An array type optical addressable potential sensor and its manufacturing method

A potential sensor and manufacturing method technology, applied in the direction of material electrochemical variables, etc., can solve the problems of unfavorable array photo-addressable potential sensor miniaturization and integration, unsatisfactory noise suppression effect, photoresist cannot be soaked for a long time, etc. Achieve the effect of being conducive to miniaturization, reducing volume and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the present invention in more detail, the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

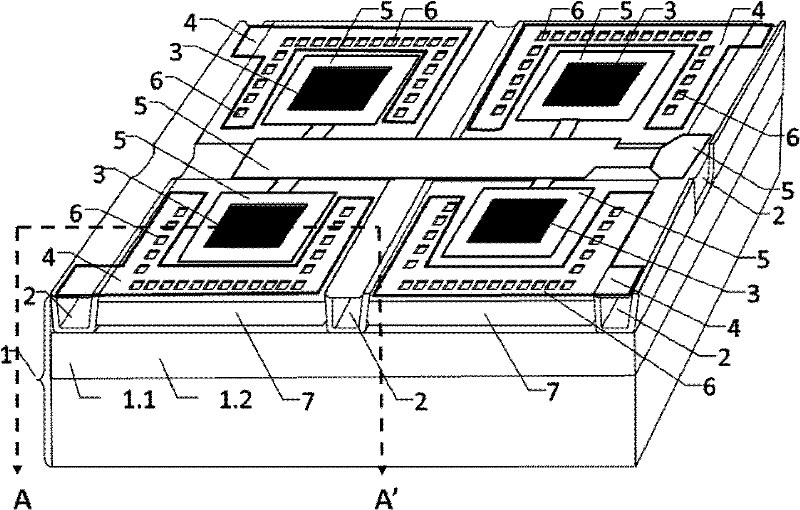

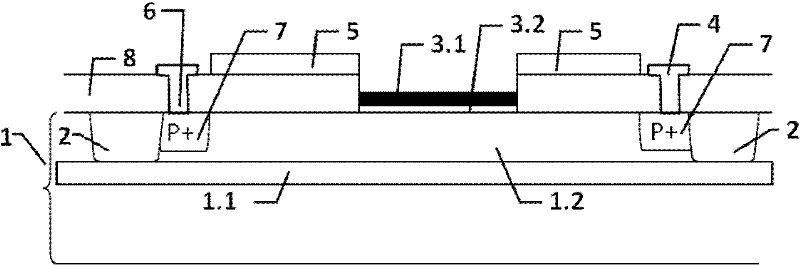

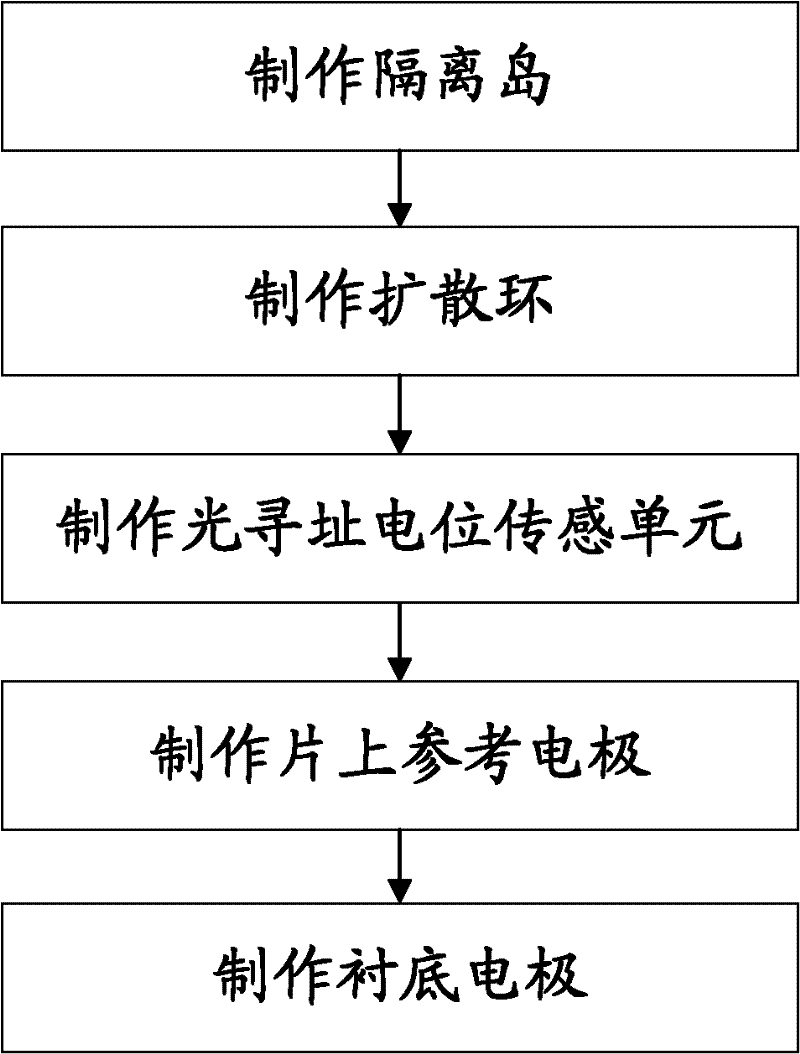

[0033] Such as figure 1 with figure 2 As shown, a 2×2 array optical addressable potential sensor includes an SOI substrate 1 and four isolation islands formed on the SOI substrate 1;

[0034] The SOI substrate 1 is provided with a silicon dioxide layer 8; the isolation island is composed of the buried oxide layer 1.1 of the SOI substrate 1 and the top silicon 1.2 provided on the SOI substrate 1 and connects the silicon dioxide layer 8 and the buried oxide layer 1.1 A ring-shaped isolation groove 2 is formed; the adjacent sides of the ring-shaped isolation groove 2 of two adjacent isolation islands merge;

[0035] A P+ diffusion ring 7 is provided on the top of the top silicon 1.2 in the isolation island, and the P+ diffusion ring 7 is connected to the annular isolati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com