In-Situ Measurement Method in Surface Quality Evaluation

A surface quality, in-situ measurement technology, applied in the direction of testing wear resistance, etc., can solve the problems of deviation of measurement results, unstable measurement results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation process of the in-situ measurement method will be described below in conjunction with the examples, and the present invention will be further described in detail. It should be understood that the examples are only for illustration of the present invention and are not intended to limit the scope of the present invention in any way.

[0027] Take a part of the workpiece to be tested as an experimental specimen, such as figure 1 As shown, the size of the specimen is 35mm×35mm×8mm, where the upper plane of the specimen is the original actual working surface of the workpiece, and the processing requirements for the rest of the specimen are: the bottom surface of the specimen is parallel to the upper plane, and the four sides of the Adjacent faces are perpendicular;

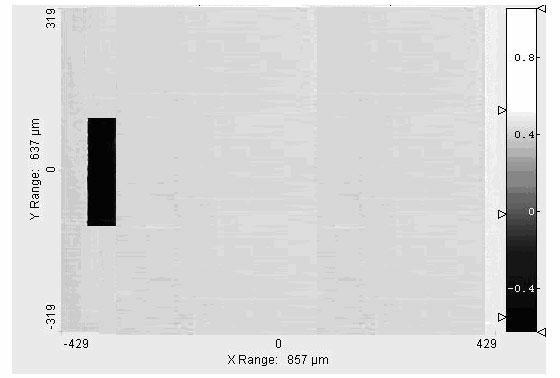

[0028] Place the test piece on the workbench of the laser engraving machine, adjust the relevant parameters of the equipment, and carve a groove on the upper plane of the test piece, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com