Electronically controlled two-way overrunning clutch

An overrunning clutch and electric control technology, applied in the direction of clutches, fluid clutches, mechanical equipment, etc., can solve the problems of complex structure, low transmission precision, no reverse gear, etc., achieve a simple and compact structure, change the traditional thinking, and respond quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

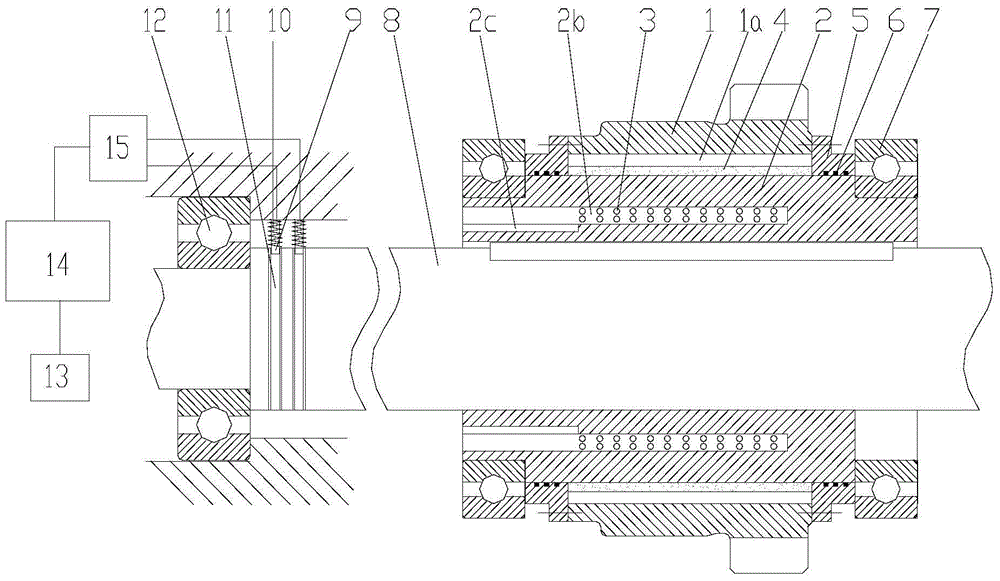

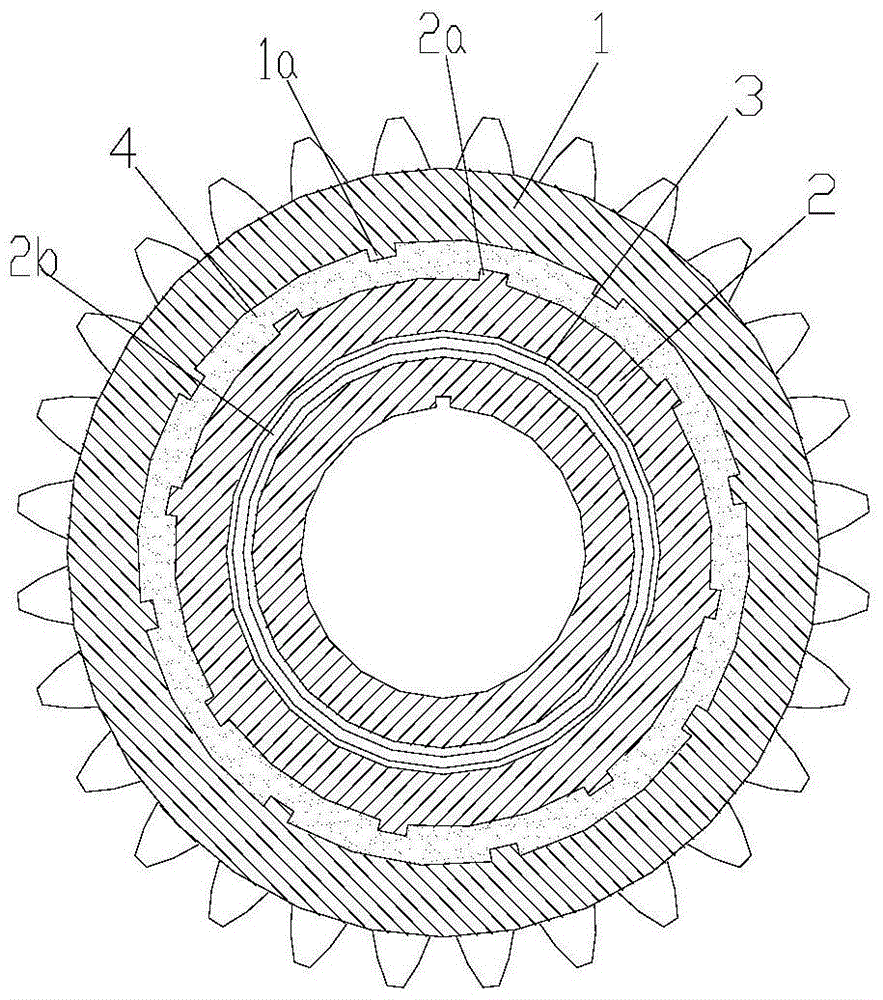

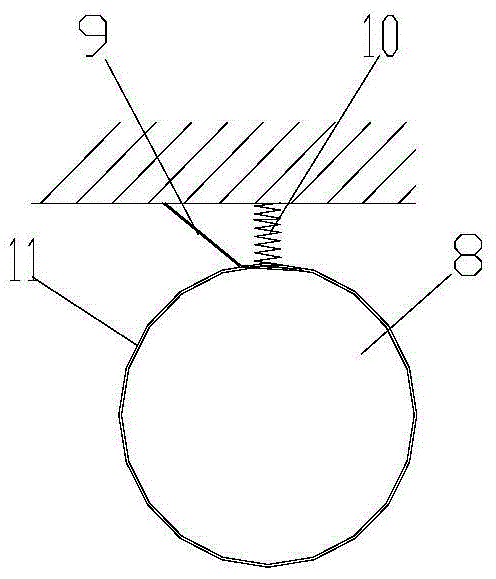

[0022] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a radial sectional view of the present invention, image 3 It is a schematic diagram of the radial structure of the conductive ring and the conductive shrapnel, as shown in the figure: the electronically controlled two-way overrunning clutch of this embodiment includes an outer ring 1 and an inner ring 2 that rotate and cooperate with each other, and the outer circle of the inner ring 2 and the outer ring 1 A sealed space is formed between the inner circles, and the sealed space is filled with magneto-rheological grease 4, and protrusions are distributed on the outer circle of the inner ring 2 and the inner circle of the outer ring 1, as shown in the figure, the protrusions 2a of the inner ring 2 and the outer circle 1 The protrusion 1a of the ring; also includes the coil 3 and the control unit acting on the magnetorheological grease 4; the coil 3 is energized to generate a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com