Heat pump pre-cooling waste heat recovery system before throttling of integrated heat pump water heater

A heat pump water heater, an integrated technology, applied in heat recovery systems, fluid heaters, energy-saving heating/cooling, etc., can solve the problems that the average energy efficiency ratio is difficult to break through, achieve lower temperature, reduce heat loss, and reduce the speed of COP value Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

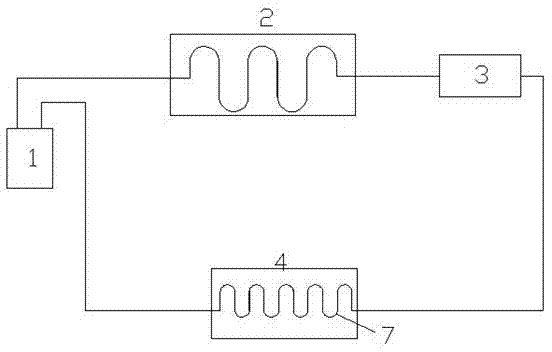

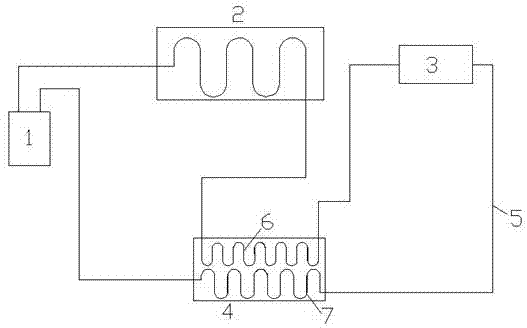

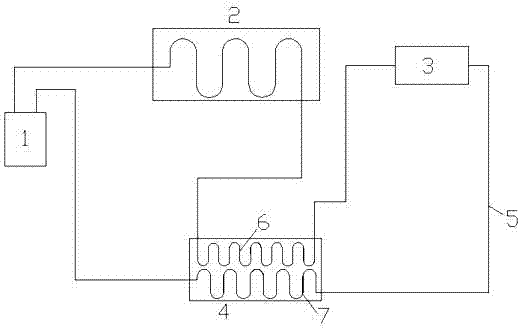

[0015] see figure 2 , the present invention is made up of compressor 1, condenser 2, throttling valve 3 and evaporator 4, is connected by pipeline 5 to form circulation therebetween, adds condensing pipe 6 in evaporator 4, and the outlet of condenser 2 passes through pipeline and evaporator The input port of the condensation pipe 6 added in 4 is connected, the output port of the condensation pipe 6 is connected with the input port of the throttle valve 3 through the pipeline, the output port of the throttle valve 3 is connected with the evaporation pipe 7 input port of the evaporator through the pipeline, and the evaporation pipe 7. The output port is connected with the input port of the compressor 1 through the pipeline, and the output port of the compressor 1 is connected with the input port of the condenser 2 through the pipeline, thus forming a heat pump circulation system.

[0016] According to the high temperature situation before the throttling after the refrigerant is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com