Dissolving heat absorption type chemical heat pump and heating or refrigerating method thereof

A chemical heat pump and heat-absorbing technology, applied in energy-saving heating/cooling, refrigerators, adsorption machines, etc., can solve the problem of inability to perform heat exchange, reliable circulation of working fluid, and inability to form the bottom temperature of the exothermic area in the high-temperature area at the bottom District and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

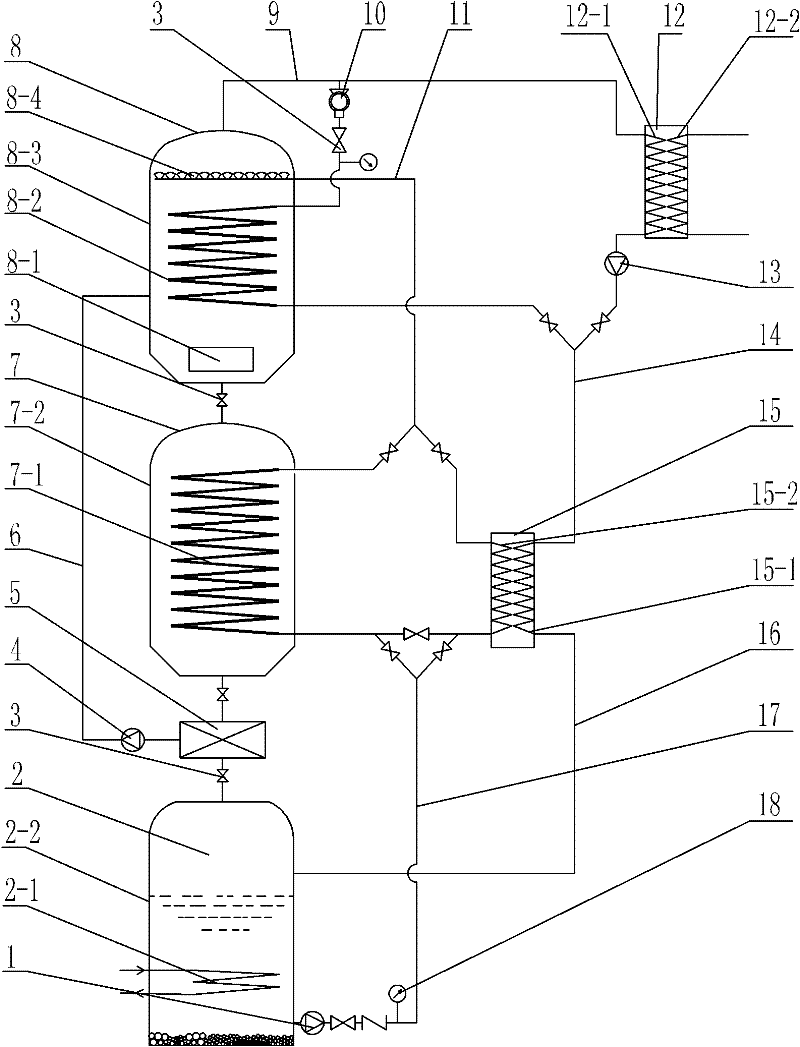

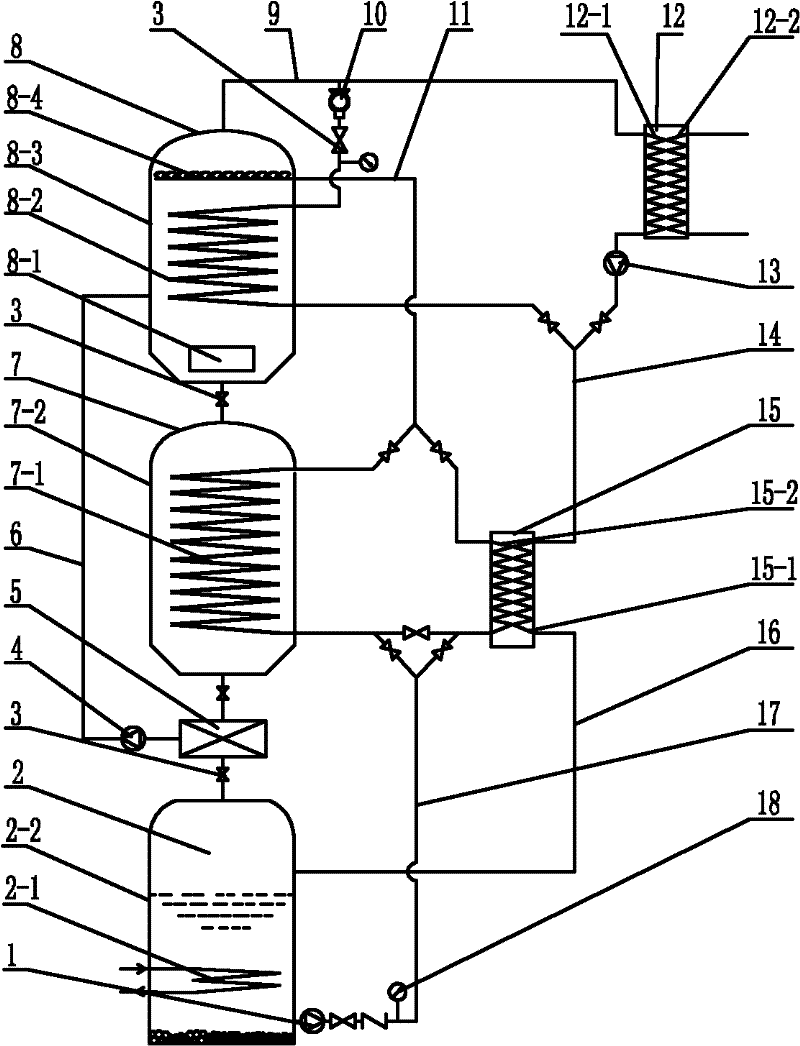

[0011] See figure 1 As shown, a kind of dissolving endothermic chemical heat pump of the present invention comprises evaporator 2, condenser 7, reactor 8, air compressor 10 and solid-liquid separator 5, circulation heat exchanger 15 and hot end heat exchanger 12. Both the circulation heat exchanger 15 and the hot end heat exchanger 12 adopt conventional plate heat exchangers. The present invention uses ammonium nitrate aqueous solution as the working medium, and the evaporator 2 includes the cold end heat exchange tube 2-1 and is arranged in the evaporation container The cold end heat exchange tube 2-1 in 2-2, the cold end heat exchange tube 2-1 communicates with the cold end user medium through the pipeline, so that the cold end user medium circulates in the cold end heat exchange tube 2-1. For heat exchange, there is an ammonium nitrate aqueous solution with a mass concentration of 47% to 54% in the evaporation container 2-2 of the present invention, which is a liquid ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com