sprocket

A sprocket and chain technology, applied in the direction of belts/chains/gears, portable lifting devices, components with teeth, etc., can solve the problems of bad influence of chain transmission devices, difficult aging, serious aging, etc., to prevent Harmful effects, reduced localized aging, reduced shattering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

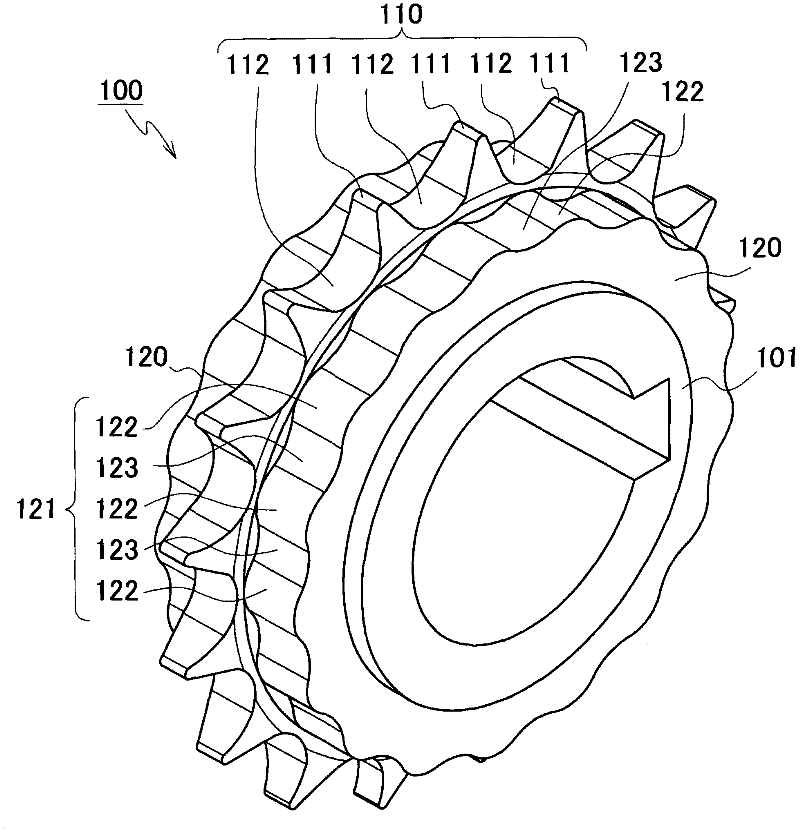

[0065] The sprocket 100 according to the first embodiment of the present invention, as Figure 1~3 As shown, a plurality of teeth 110 with tooth tips 111 and dedendums 112 are formed on the peripheral surface of the sprocket body 101, and outer peripheral surfaces 121 are provided on both sides of the sprocket body 101 to contact the chain plate of the chain. And a washer 120 made of elastic components.

[0066] On the outer peripheral surface 121 of the washer 120 located on both sides, convex portions 122 and concave portions 123 as non-cylindrical portions are alternately provided along the circumferential direction, and the convex portions 122 are formed at positions corresponding to the dedendum 112. The portion 123 is formed at a position corresponding to the tooth tip 111 . In addition, the "corresponding position" in the circumferential direction referred to in this specification means a position having the same angle as that of the sprocket 100 in the circumferential...

Embodiment 2

[0072] Compared with the first embodiment, the sprocket 200 described in the second embodiment of the present invention is only different in the washer 220, while other structures are the same. Such as Figure 4 The washer 220 of the sprocket 200 according to the second embodiment shown has an inner link plate 151 similar to the conventional washer at a position corresponding to the inner link plate 151 of the chain 150 in the width direction of the outer peripheral surface 221. The central part along the longitudinal direction contacts and presses the cylindrical surface 221U.

[0073] At a position corresponding to the outer link plate 155 of the chain 150 in the width direction on the outer peripheral surface 221 of the washer 220, there are provided convex portions 222 and concave portions 223 alternately in the circumferential direction as in the first embodiment. . The convex portion 222 is formed at a position corresponding to the tooth tip 211 , and the concave porti...

Embodiment 3

[0077] The sprocket 300 according to the third embodiment of the present invention is as follows: Figure 6 As shown, compared with the first embodiment or the second embodiment, only the radii of the convex portion 322 and the concave portion 323 of the washer 320 are different, and other structures are the same. The washer 320 of the sprocket 300 according to the third embodiment is alternately provided with convex portions 322L, 322S with different maximum radii and concave portions 323L, 323M, 323S with different minimum radii in the circumferential direction.

[0078] Accordingly, the state of the elastic material being pressed by the chain varies with each tooth of the sprocket 300, so the impact and knocking sound caused by the contact at the time of meshing are different for each tooth, thereby suppressing the vibration due to periodicity. Occurrence of resonance caused by permanent noise and shock.

[0079] In addition, only one of the maximum radius of the convex po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com