A constant-resistance energy-absorbing bolt for strengthening large-deformation rock mass

A large deformation and anti-absorption technology, applied in construction, infrastructure engineering, sheet pile walls, etc., can solve the problems of poor corrosion resistance and durability, low resistance, large exposure length, etc., to achieve good corrosion resistance and durability, production and The effect of convenient construction and increased extension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

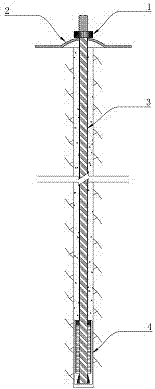

[0025] see figure 1 , the constant-resistance energy-absorbing bolt of the present invention includes a nut (1), a tray (2), a rod body (3) and a constant-resistance energy-absorbing device (4), and the constant-resistance energy-absorbing device (4) is installed on the head of the bolt, The tray (2) is installed on the tail of the anchor rod through the nut (1).

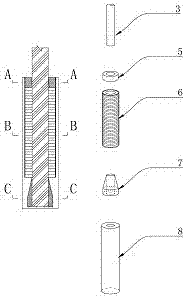

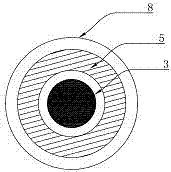

[0026] The rod body (3) is a smooth rod body with a circular cross-section, threads are provided at both ends, and the middle part is wrapped with a plastic sleeve.

[0027] join Figure 2~5 , the constant-resistance energy-absorbing device (4) is installed on the head of the anchor rod, and consists of an anchorage (5), an expandable cylinder (6), a conical cylinder (7) and a protective cover (8), and the anchor rod body ( 3) The head passes through the anchor (5) and the expandable cylinder (6) in sequence and is fixedly connected with the conical cylinder (7). The protective cover is wrapped around the anchor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com