Novel synthetic concrete material and preparation method

A technology of concrete and concrete surface, applied in the field of concrete, can solve the problems of restricting the wide application of concrete, aggravating concrete maintenance work, low tensile strength, etc., and achieve the effects of increasing ultimate elongation, reducing brittleness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

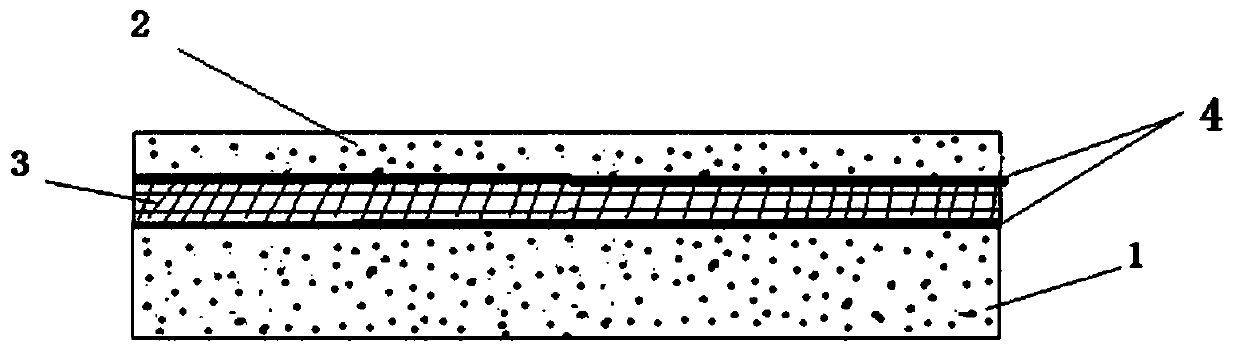

[0025] figure 1 It is a structural schematic diagram of a novel synthetic concrete material of the present invention. It can be seen from this figure that a novel synthetic concrete material of the present invention consists of a concrete body 1, a concrete surface layer 2, and a glass fiber geogrid 3 between the concrete body 1 and the concrete surface layer 2.

[0026] The fiberglass geogrid 3 is a planar grid-like material constructed on the basis of glass fibers, and the fiberglass geogrid 3 is laid between the concrete body 1 and the concrete surface 2, and the adhesive layer oil is used to 4 are fixedly connected with the concrete main body 1 and the concrete surface layer 2 respectively. In this embodiment, the thickness of the glass fiber geogrid 3 is 60-100 mm, and the thickness of the concrete surface layer 2 is 60-100 mm.

[0027] The mass of the glass fiber geogrid 3 is 0.03%-0.055% of the total mass of the new synthetic concrete material, and the mass of the adh...

Embodiment 2

[0039] Embodiment 2: The weight percentage of cement, river sand, gravel, and water is 1:2:3:0.6. The mass of the glass fiber geogrid 3 accounts for 0.055% of the total mass, and the mass of the sticky layer oil 4 accounts for 0.025% of the total mass of the new synthetic concrete material.

Embodiment 3

[0040] Embodiment 3: The weight percentage of cement, river sand, gravel, and water is 1: 1.6: 2.7: 0.5. The mass of the glass fiber geogrid 3 accounts for 0.045% of the total mass, and the mass of the sticky layer oil 4 accounts for 0.02% of the total mass of the new synthetic concrete material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com