Interchangeable wear-resistant compact spinning special-shaped suction pipe

An air suction duct, compact spinning technology, applied in the field of spinning, can solve the problems of large difference in the stability of the surface wear-resistant layer, great harm to the health of operators, environmental pollution, etc., to reduce the use cost and management cost, The effect of shortening the manufacturing process and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

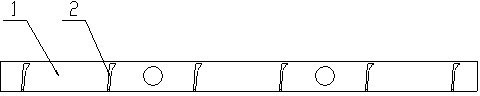

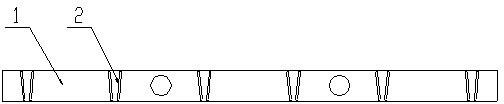

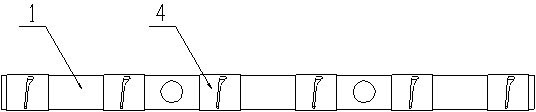

[0022] see Figure 3~Figure 5 , the present invention relates to an exchangeable wear-resistant compact spinning special-shaped suction pipe, which includes a suction pipe body 1, which is extruded or drawn from aluminum alloy or other metal materials. The front of the pipe body 1 is provided with a plurality of diversion openings 3, on which a suction hood 4 is arranged, and the suction hood 4 is fixedly connected with the suction pipe body 1, and the suction hood 4 is provided with Gathering groove 2 is arranged, and suction hood 4 is made of high-strength wear-resistant material, and suction hood 4 is made of stainless steel in the present embodiment.

[0023] The suction hood 4 can be tightly integrated with the suction pipe body 1 by means of mechanical locking, bonding with high-strength glue, welding or moulding.

[0024] see Figure 5~Figure 9 According to different requirements of the spinning process, the gathering grooves 2 provided on the suction hood 4 can be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com