Large tonnage forklift

A tonnage fork and front frame technology, which is applied in the field of large tonnage forklifts, can solve the problems of prominent safety problems, limited loading capacity, and inability to load stone blocks, and achieves the effect of less fuel consumption and large loading capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

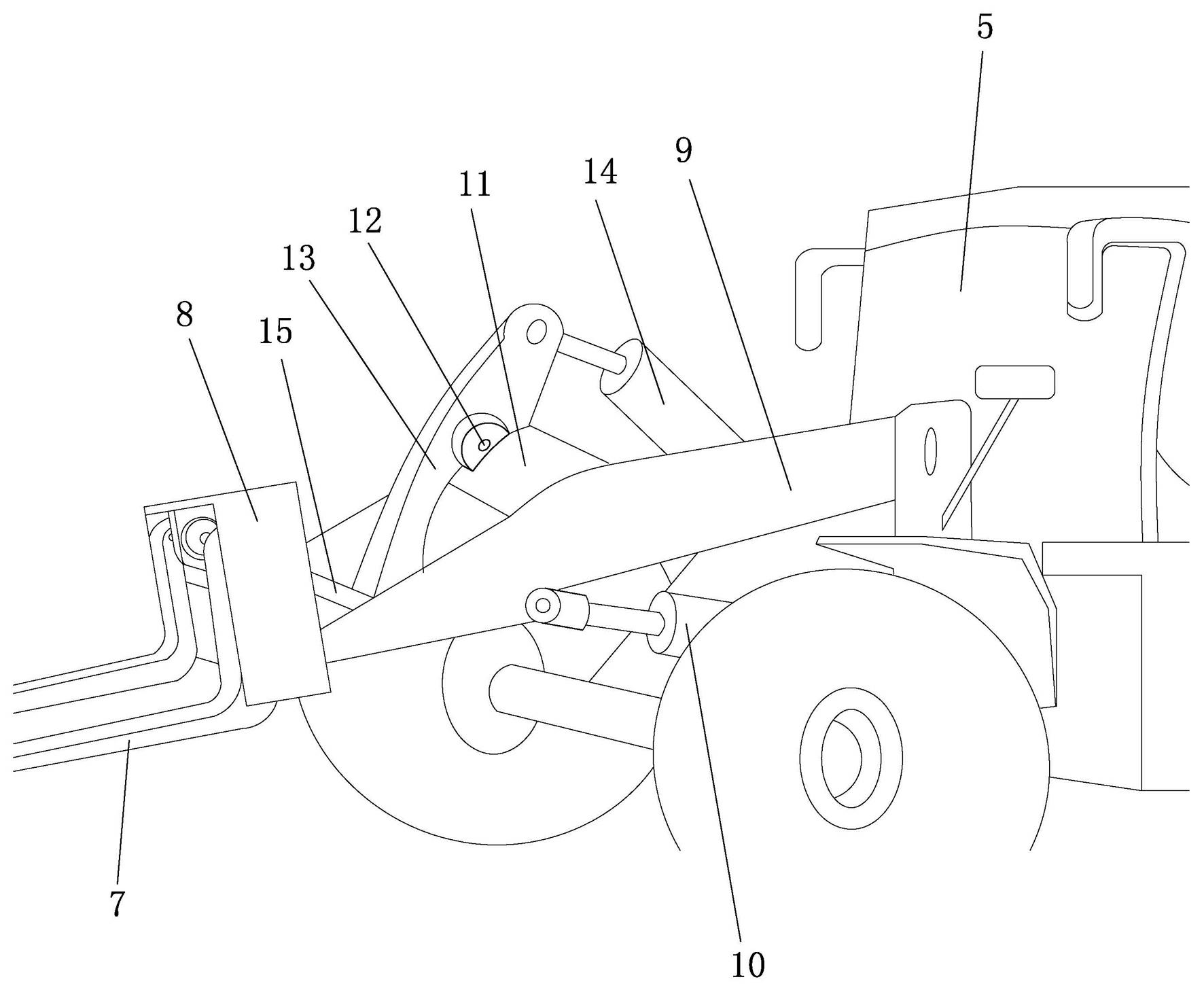

[0014] Large-tonnage forklift truck described in the present invention, such as figure 1 , 2 , 3, 4, it includes rear frame 1, counterweight 2, drive axle support shaft 3, gearbox 4, cab 5, front frame 6, fork frame 8 with double forks 7, The front frame 6 is provided with two symmetrical booms 9 connected with the cargo fork frame 8, and each boom 9 is connected with a lifting cylinder 10; The rocking arm 13 of 12, the rear end of rocking arm 13 is connected with turning oil cylinder 14, and the front end of rocking arm 13 is connected with pallet fork frame 8 through pull rod 15. The lifting cylinder 10 and the boom 9 are used to adjust the height of the double forks 7, and the turning cylinder 14, the rocking arm 13 with the rotating shaft 12 and the pull rod 15 are used to adjust the angle of the double forks 7.

[0015] The horizontal length of the two booms of the present invention is 2755 millimeters; the connection point 16 of the boom on the front frame to the conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com