A sieving machine conveying device for toner production

A sieving machine and toner technology, applied in packaging, etc., can solve the problems of easily leaking toner waste, frequent failures, leakage of finished toner, etc., and achieve the effects of saving maintenance costs, reducing waste, and controlling leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

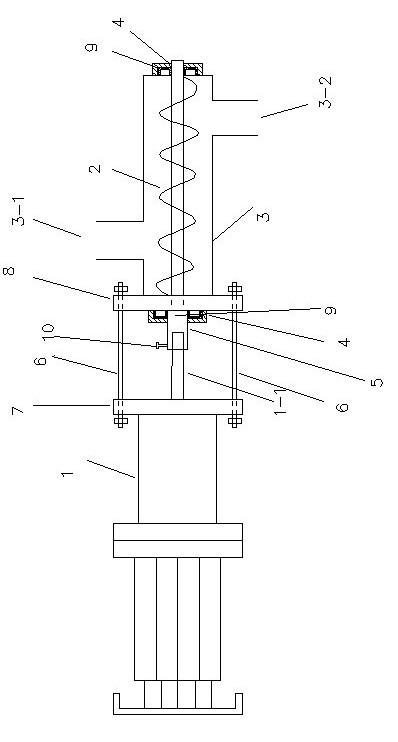

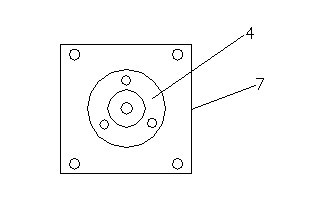

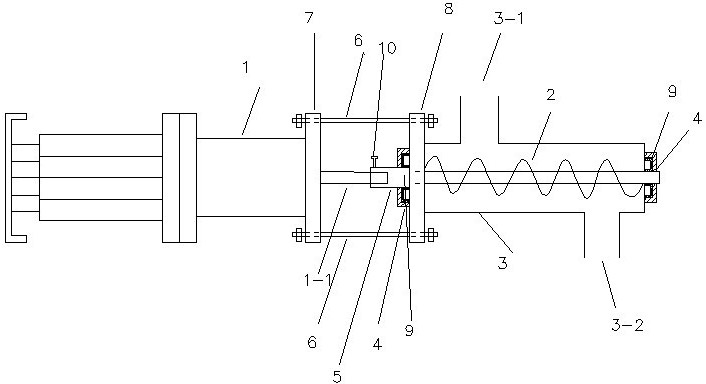

[0008] Such as figure 1 , figure 2 As shown, the conveying device of the sieving machine used for toner production includes an AC single-phase reducer 1 fixed with a reducer flange 7, a conveying screw 2, a conveying pipe 3, a shaft sleeve 4 and a connecting sleeve 5, and Including the delivery pipe flange 8 and the oil sealing ring 9. Weld and fix one end of the flange 8 of the feed pipe to one end of the feed pipe 3, place the feed screw 2 in the feed pipe 3, connect a shaft sleeve 4 equipped with an oil-containing sealing ring 9 and the end of the feed pipe 3 The other end is screwed and fixed, the other end of the feeding screw 2 passes through the feeding pipe flange 8 and is screwed and fixed with the connecting sleeve 5 arranged in another shaft sleeve 4 equipped with an oil-containing sealing ring 9 , and the reducer flange 7 It is fixedly connected with the delivery pipe flange 8 through four connecting rods 6, so that a certain space is obtained between the reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com