A welding method for double-zero aluminum foil joints

A technology of double-zero aluminum foil and welding method, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of insufficient welding strength, adhesion between pad and aluminum foil, and unsatisfactory effect, and achieve overall quality improvement, The effect of reducing welding defects and cleaning the welding area without contamination

Active Publication Date: 2011-12-21

JIANGSU DAYA ALUMINUM

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The problem of fixing the welding lap was solved. The main problem was the adhesion between the pad and the aluminum foil during welding. The applicant had tried to smear the pad with base oil or re-weld the aluminum foil, but the effect was not ideal, mainly because the weld seam was weak. Seriously, the welding strength cannot meet the requirements at all

Method used

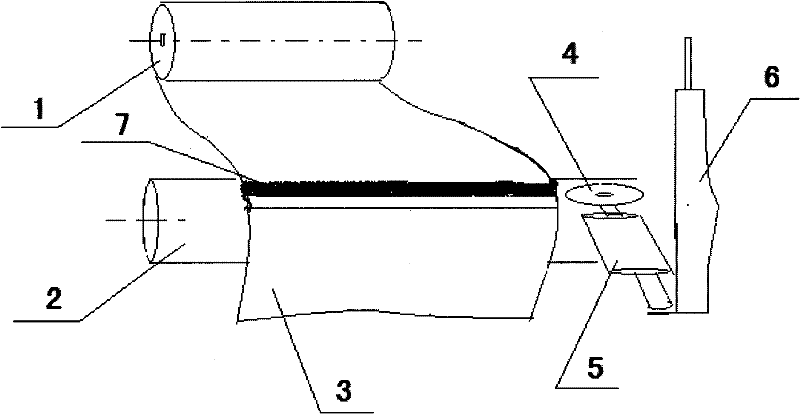

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

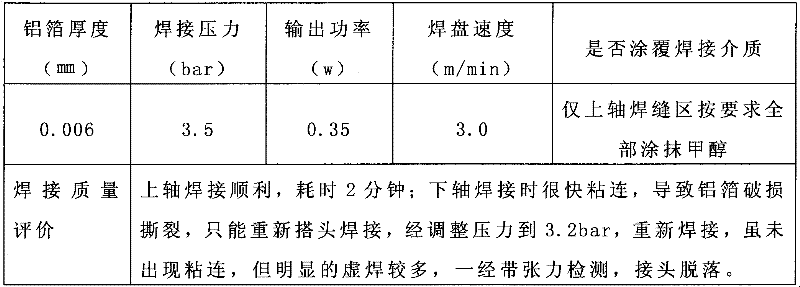

Embodiment 1

[0032]

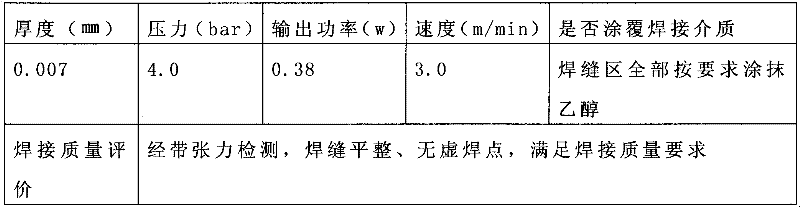

Embodiment 2

[0034]

Embodiment 3

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a double-zero aluminum foil connector welding method. The upper part and the lower part of a double-zero aluminum foil connector are separated after precise rolling and dual combination and are respectively lapped on an upper anvil roller and a lower anvil roller coated by a welding medium, and lapping head parts are reserved; double-zero aluminum foils on an upper rollingshaft and a lower rolling shaft are respectively lapped on the upper double-zero aluminum foil and the lower double-zero aluminum foil through lapping joints, and the welding medium is coated betweenthe double-zero aluminum foil on the upper rolling shaft and the upper double-zero aluminum foil and between the double-zero aluminum foil on the lower rolling shaft and the lower double-zero aluminum foil; the joints are fixed, parameters of the welding process are adjusted, a welding machine is started, the lapping head areas of the double-zero aluminum foils are coated by the welding medium, aweld seam with a smooth surface is formed after a welding plate passes through the lapping head areas coated by the welding medium, and the welding medium adopts a volatile organic solvent. The double-zero aluminum foil can be effectively prevented from being bonded with the ultrasonic welding plate during welding, the weld seam can be maintained smooth, the welding area is clean and pollution-free, and anhydrous ethyl alcohol is preferred to be used as the welding medium.

Description

technical field [0001] The invention belongs to the technical field of non-ferrous metallurgical processing, and in particular relates to a welding method for double-zero aluminum foil joints which uses welding medium to improve welding efficiency and effect during the welding process. Background technique [0002] Double-zero aluminum foil generally refers to aluminum foil with a thickness of less than 0.009mm. It can be described as "thin as a cicada's wing and can be broken by blowing bombs". It has light-shielding, fresh-keeping, and anti-corrosion properties. Lining materials are combined with other packaging materials such as plastics and paper to enhance the strength of the packaging materials. Aluminum foil is required to have good formability, continuity and a bright and clean surface during use, and it is usually delivered in an annealed soft state. [0003] In the composite process of aluminum foil and other packaging materials, once the tape is broken, the compo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K31/02B23K35/362

Inventor 贾建新刘文中

Owner JIANGSU DAYA ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com