Device for scraping and cutting on semiconductor device chip glass passive film and using method thereof

A glass passivation, device chip technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

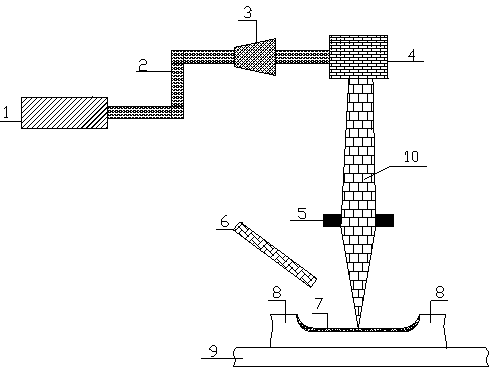

[0032] Such as figure 1 As shown, the device of the present invention for scribing on the glass passivation film of a semiconductor device chip includes a laser 1 capable of generating a violet laser beam 10, an optical transmission channel 2 for the optical transmission of the violet laser beam 10, and diverging the violet laser beam 10. The beam expander 3, the deflection device 4 that changes the parallel direction of the violet laser beam 10, the optical focusing device 5 that focuses the divergent violet laser beam 10, and the blowing exhaust device that blows away the dust generated during the scribing process 6. Protect the glass passivation film 7 on the surface of the single-table semiconductor device chip and the operating platform 9 for placing the single-table semiconductor device chip 8, the laser 1 is connected to the optical transmission channel 2, and the beam expander 3 and the deflection device 4 are set On the optical transmission channel 2 , the optical fo...

Embodiment 2

[0045] Such as figure 1 As shown, the structure of the device of the present invention for scribing on the glass passivation film of the semiconductor device chip is the same as that of Embodiment 1.

[0046] The above-mentioned scribing device performs scribing on a single-mesa semiconductor device chip with a thickness of 300 μm, and its use method includes the following steps:

[0047] a. First adjust the crystal temperature value by 0.1°C each time, and measure the power value with a power measuring device to find the crystal temperature value suitable for the normal operation of the crystal to be 25°C. At the same time, ensure that the temperature and humidity of the working environment are stable, and ensure that the laser 1 works normally and stably;

[0048] b. Adjust the horizontal polarizer of the optical transmission channel 2 to ensure that the violet laser beam 10 is horizontal from the laser emission hole to the entrance of the beam expander 3;

[0049] c. Adju...

Embodiment 3

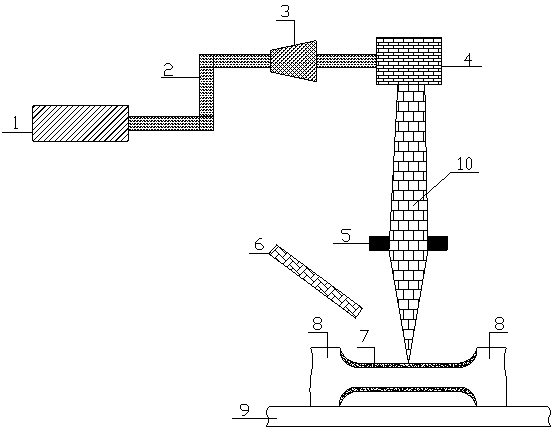

[0058] Such as figure 2 As shown, the device of the present invention for scribing on the glass passivation film of a semiconductor device chip includes a laser 1 capable of generating a violet laser beam 10, an optical path transmission channel 2 for the optical path transmission of the violet laser beam, and a beam expander for diverging the violet laser beam Device 3. The deflection device for changing the parallel direction of the purple laser beam 10. 4. The optical focusing device for focusing the divergent purple laser beam. The glass passivation film 7 on the surface of the mesa semiconductor device chip 8 and the operating platform 9 on which the double mesa semiconductor device chip 8 is placed, the laser 1 is connected to the optical transmission channel 2, the beam expander 3 and the deflection device 4 are placed on the optical transmission On the channel 2 , the optical focusing device 5 is arranged on both sides of the violet laser beam 10 , and the air blowing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com