High-frequency pulse power supply for ultra-fine micro-EDM machine tools

A technology for processing machine tools and high-frequency pulses, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve problems such as limiting the scope of application, and achieve the effect of improving maintenance efficiency, stable performance, and high program security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

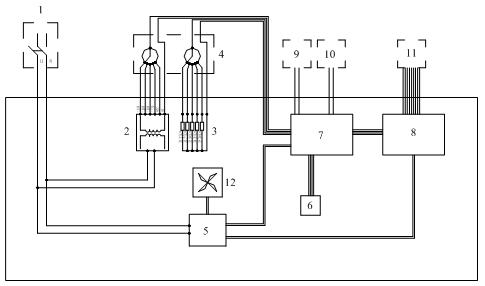

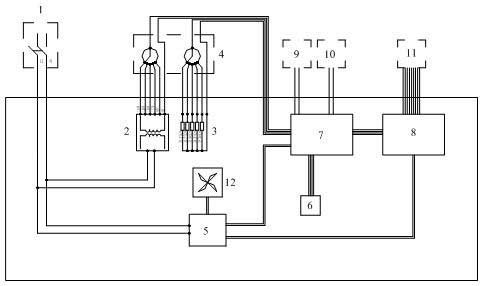

[0029] figure 1 It is an overall structure diagram of the present invention. like figure 1 As shown, the present invention at least includes a multi-speed transformer 2 , a multi-speed resistance 3 , a switching power supply 5 , a digital display DC voltmeter 6 , a high-frequency discharge circuit module 7 , a main control module 8 and a fan 12 . In actual use, the components that can be selected and connected according to needs include a control switch 1 , a multi-level voltage resistance adjustment switch 4 , an external voltmeter 9 , an external ammeter 10 and a host computer 11 .

[0030] like figure 1 As shown, the control switch 1 controls the power on and off of the switching power supply 5 and the multi-speed transformer 2 . The external multi-level voltage resistance adjustment switch 4 correspondingly adjusts the voltage of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com