Electromagnetic clamping device for mechanical milling head

A technology of clamping device and milling head, which is applied in positioning devices, metal processing mechanical parts, clamping and other directions to achieve the effects of improving processing accuracy, economical cost, and improving processing range and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

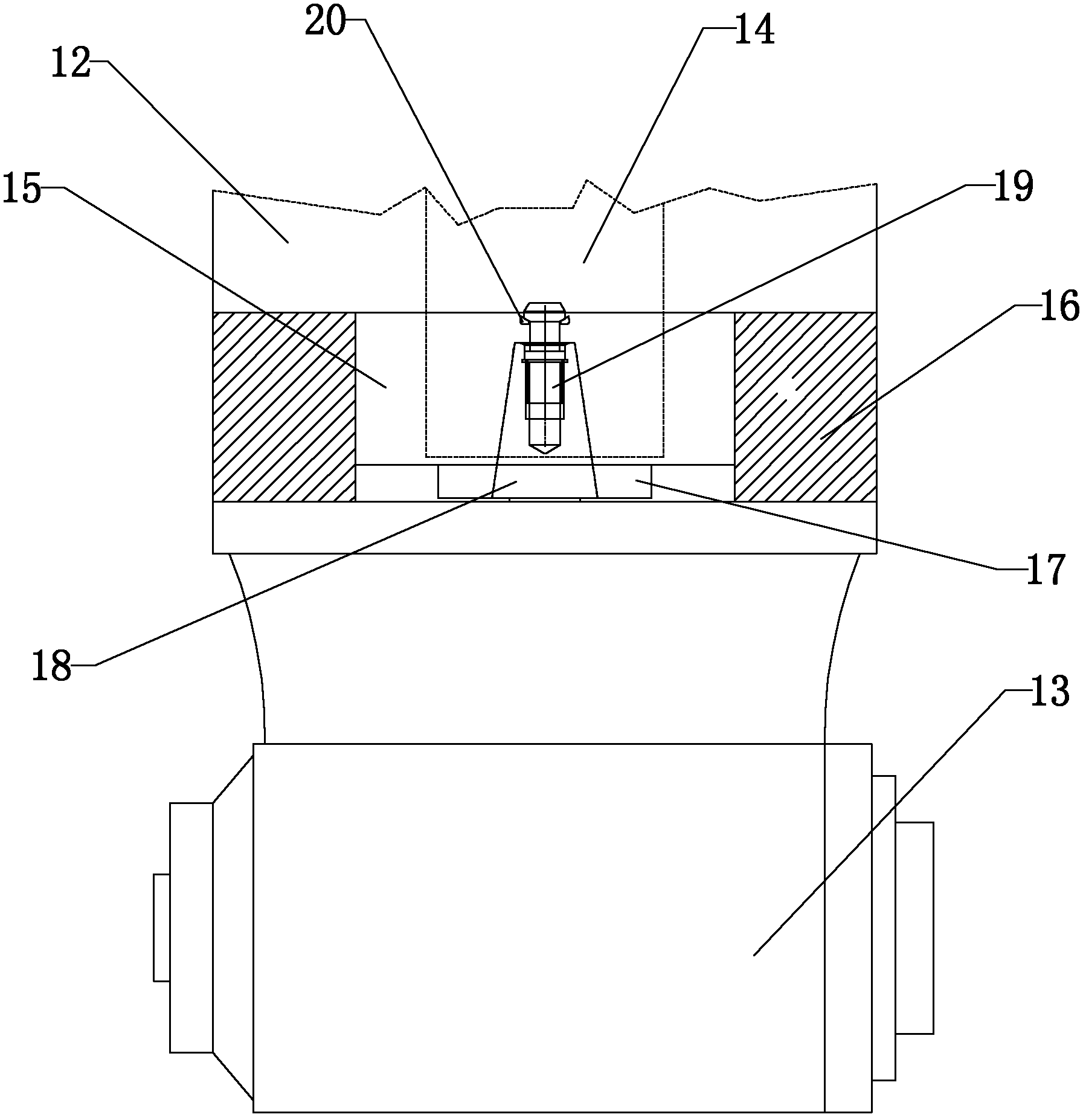

[0018] Such as Figure 3-4 As shown, an electromagnetic clamping device for a mechanical milling head described in the embodiment of the present invention includes a ram 12 and a mechanical milling head 13, the bottom of the ram 12 is provided with a protrusion 15, and the ram 12 and the protrusion The inside of 15 is provided with a main shaft 17, one end of the main shaft 17 is connected to the clamping system 14, the other end of the main shaft 17 is provided with a tapered handle 18, and the top of the tapered handle 18 is provided with a pull claw 20, and the bottom of the protrusion 15 is provided with a mechanical The top of the milling head 13 and the mechanical milling head 13 are provided with a pull stud 19 with an integrated structure, the pull stud 19 is fixed by the pull claw 20, and an electromagnet 16 positioned outside the protrusion 15 is arranged below the ram 12 .

[0019] During use, move upwards until the clamping system 14 clamps the pull stud 19 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com