An aluminum fin stamping die

A stamping die and aluminum fin technology, applied in perforation tools, forming tools, manufacturing tools, etc., can solve the problems of high production cost, poor product quality, cracks around the perforation of aluminum foil, etc., to reduce production costs and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

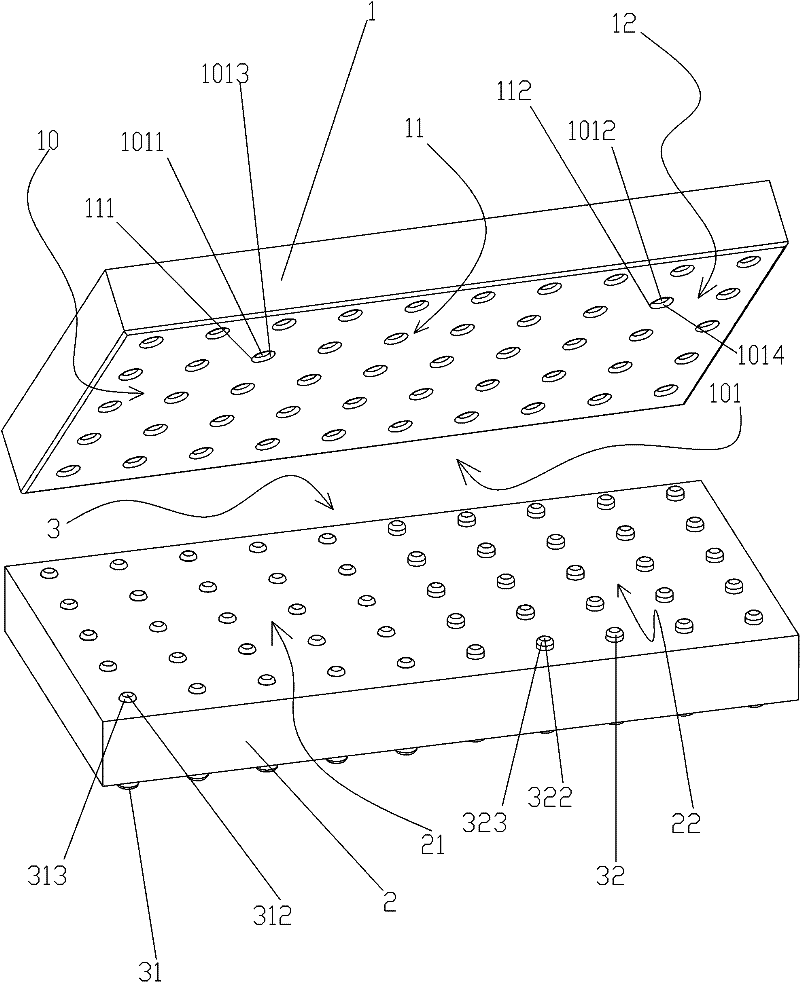

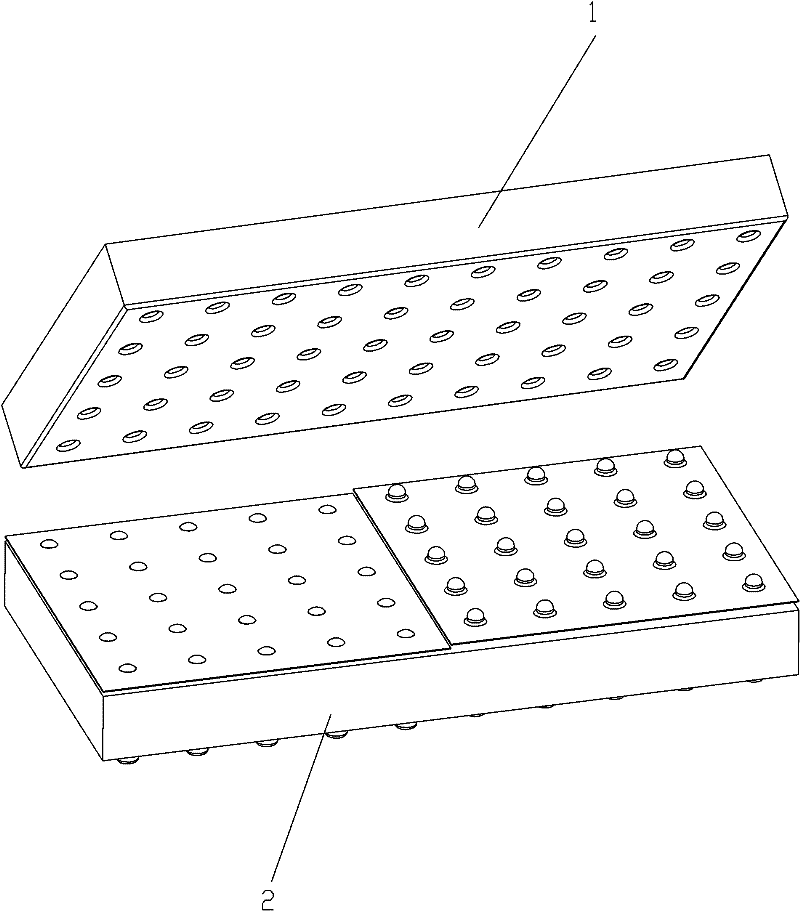

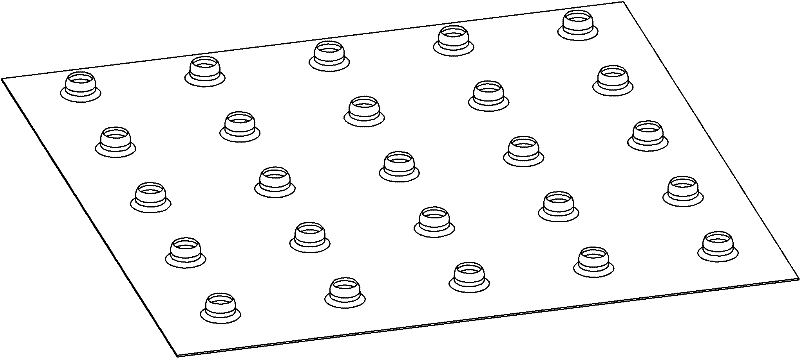

[0021] A hot aluminum fin stamping die, comprising an upper template 1 and a lower template 2, characterized in that: the lower template 2 is equipped with a ball head punch 3 protruding from the lower template 2, and the upper template 1 is provided with a circular die cavity 101 in which the ball-tipped punch 3 can be inserted correspondingly.

[0022] The upper template 1 is equipped with a die body 11 , and the die cavity 101 is set in the die body 11 .

[0023] The upper template 1 includes a first step area 10 of an upper die and a second step area 12 of an upper die, and the die body 11 includes a first Step die body 111 and the second step die body 112 installed in the second step area 12 of the upper mold, the die cavity 101 includes a The first step die cavity 1011 in the die body 111 and the second step die cavity 1012 arranged in the second step die body 112, the first step die cavity 1011 and the second step die cavity 1012 The lower cavity of the second step di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com