Device for descaling by high-pressure water

A high-pressure water descaling and high-pressure water technology, applied in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of poor scale removal effect, impact on production quality, high labor intensity, etc. Efficiency and tube forging production efficiency, improve inner surface quality, avoid labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

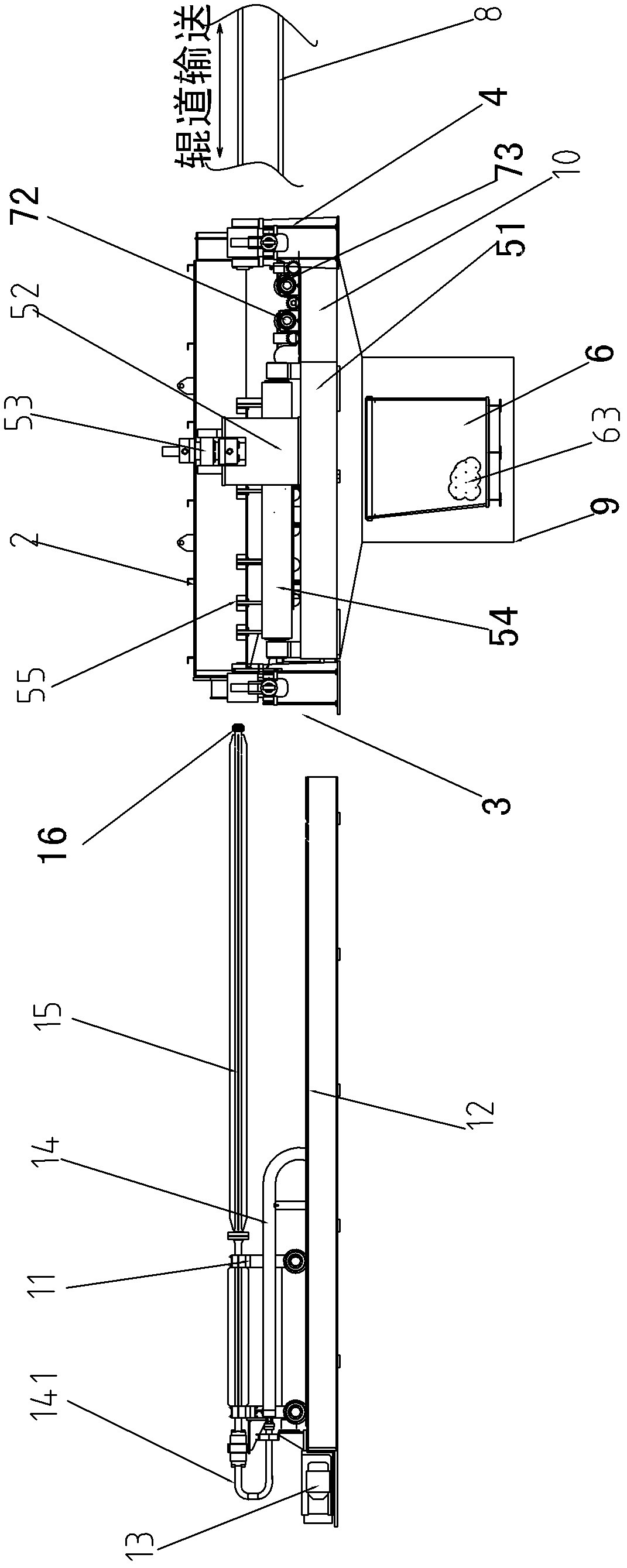

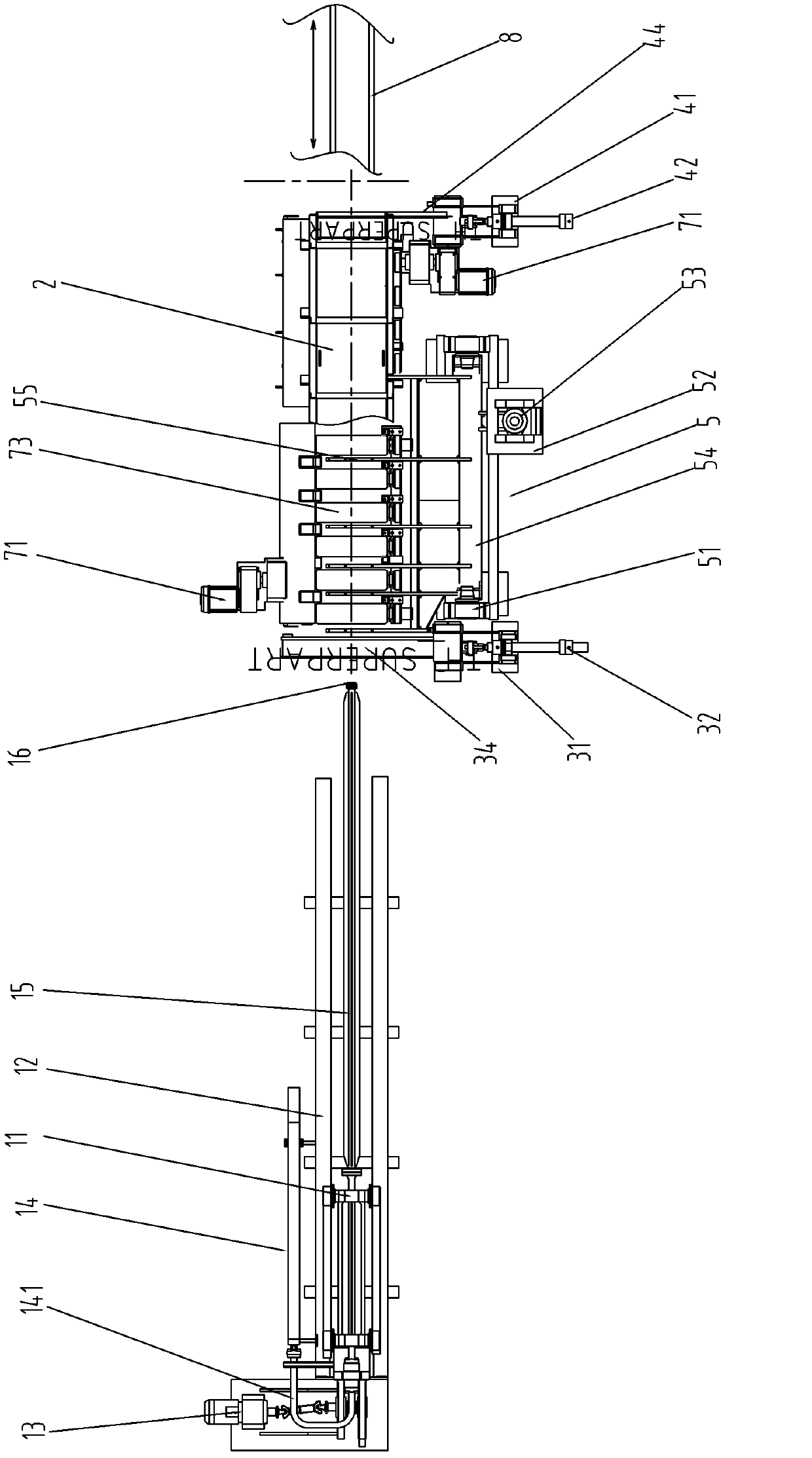

[0022] Such as figure 1 , 2 As shown, the high-pressure water descaling equipment of the present invention includes a frame 10, a high-pressure water delivery device, a shield 2, a left baffle closing device 3, a right baffle closing device 4, an inlet and outlet roller table, a centering device 5, an oxidation Skin collection device6.

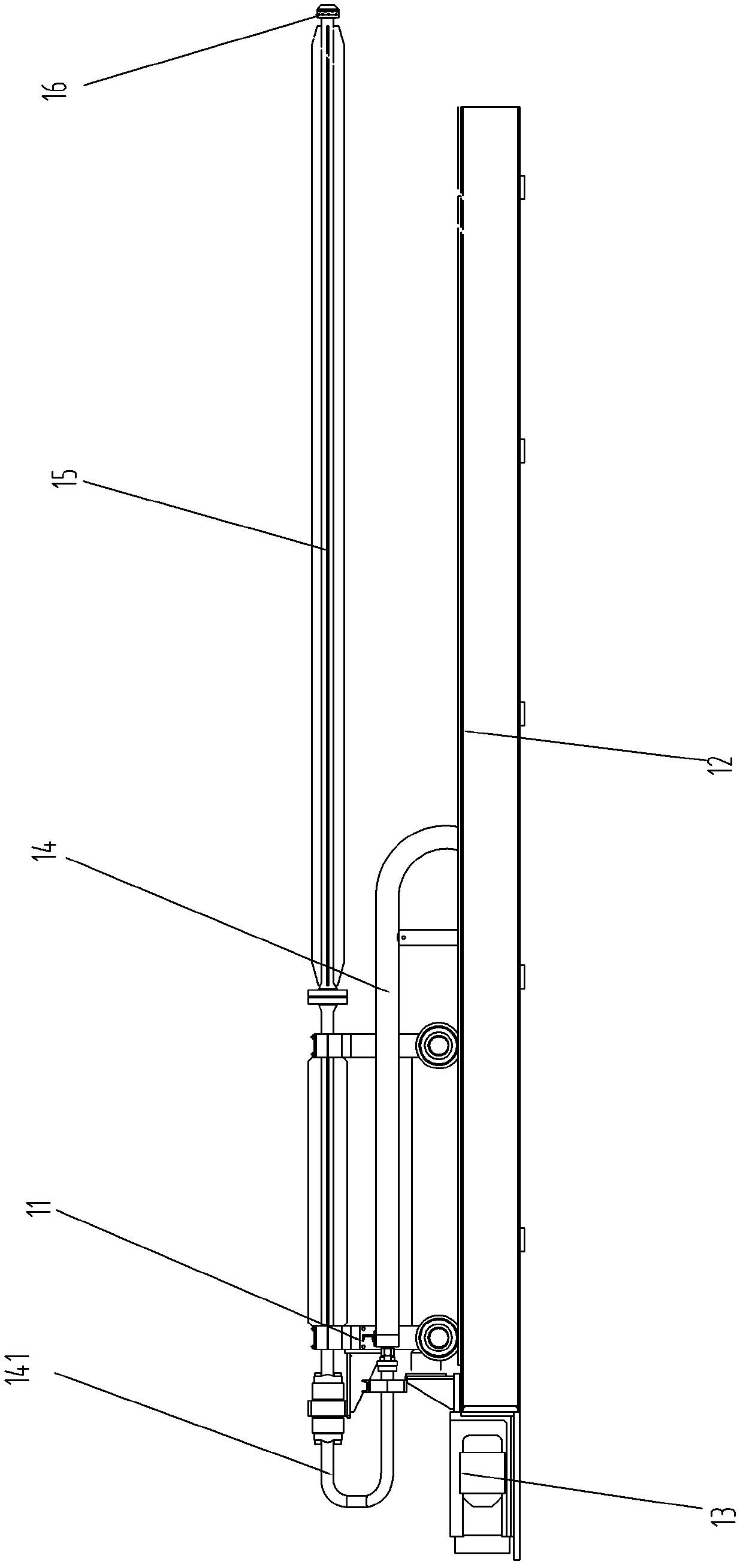

[0023] combine image 3 As shown, the high-pressure water delivery device is located on the left side of the shield, including a trolley 11, a track 12, a geared motor 13, a tank chain 14, a high-pressure water pipe 15, and a nozzle 16. The trolley 11 is located on the track 12, and the geared motor 13 and the trolley 11 The wheel shaft is connected by sprocket chain transmission, and the reduction motor 13 is a frequency conversion reduction motor, which can realize the forward and backward movement of the dolly 11. The reduction motor 13 has a rotary encoder and a brake, which can be positioned accurately. The tank chain 14 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com