Materials for Organic Electroluminescent Devices

A technology of general formula and compound, applied in the field of materials for organic electroluminescent devices, can solve the problems of low efficiency, blocking vapor deposition source, difficult realization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

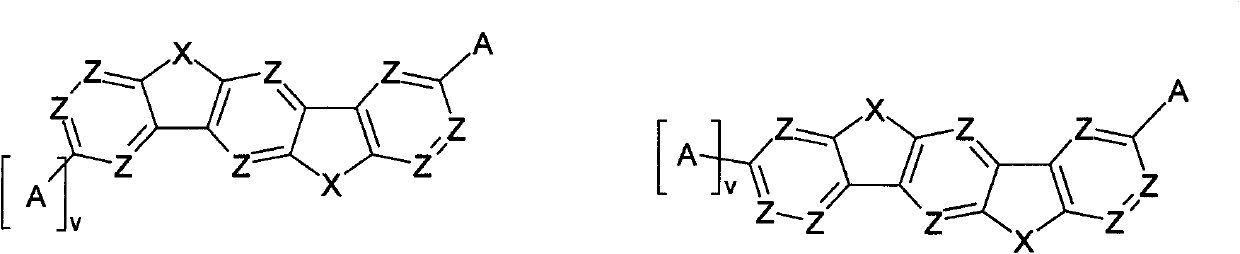

Image

Examples

Embodiment 1

[0146] a) Synthesis of thioethers

[0147]

[0148] 200g (732mmol) 2-bromo-9,9-dimethyl-9H-fluorene, 122.9g (732mmol) 2-methylsulfanylphenylboronic acid and 202g (950mmol) K 2 CO 3 Suspended in 850ml THF and 850ml water, the mixture was washed with N 2 After saturation, 3.3 g (2.9 mmol) of tetrakis(triphenylphosphine)palladium(0) were added and the mixture was heated at the boil for 2 hours. The mixture was poured into 3 L of a 1:1:1 mixture of water / MeOH / 6M HCl, the beige precipitate was filtered off with suction, washed with water and dried. according to 1 The product content determined by H-NMR was about 95%, and the total yield was 190 g (82%).

[0149] b) oxidation

[0150]

[0151] First 196 g (619.3 mmol) of the compound from a) were introduced under protective gas into 2.3 L of glacial acetic acid and 250 ml of dichloromethane and cooled to 0°C. To this solution was added dropwise 1.1 L (619 mmol) of 30% H 2 o 2 solution, and the mixture was stirred overn...

Embodiment 2-9

[0161] Examples 2-9: Fabrication of OLEDs

[0162] The inventive OLEDs are produced by the general method according to WO 04 / 058911, which is adapted to the conditions described here (layer-thickness variation, materials used).

[0163] Results for various OLEDs are given in Examples 2 to 9 below. A glass plate coated with structured ITO (indium tin oxide) forms the matrix of the OLED. For improved processing, 20 nm of PEDOT (poly(3,4-ethylenedioxy-2,5-thiophene), applied by spin coating from water, purchased from H.C. Starck, Goslar, Germany) was applied to the substrate superior. The OLED consists of the following sequential layers: substrate / PEDOT 20nm / HIL1 5nm / hole transport layer (HTM) 20, 110 or 200nm / NPB 20nm / emissive layer (EML) 30 or 40nm / electron transport layer (ETM) 20nm and finally of the cathode.

[0164] Materials other than PEDOT were applied by thermal vapor deposition in a vacuum chamber. The emitting layer here always consists of a matrix material (host...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com