Hydrothermal preparation method of copper-doped zinc oxide composite lithium iron phosphate cathode material

A technology of composite lithium iron phosphate and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of restricting commercial development and low electronic and ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

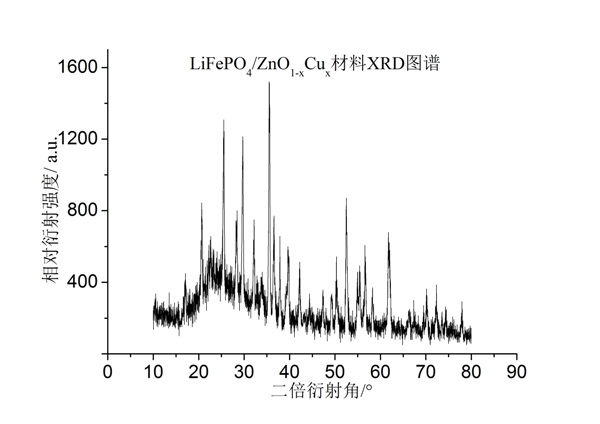

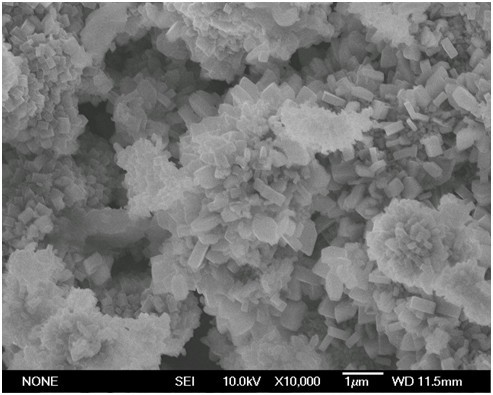

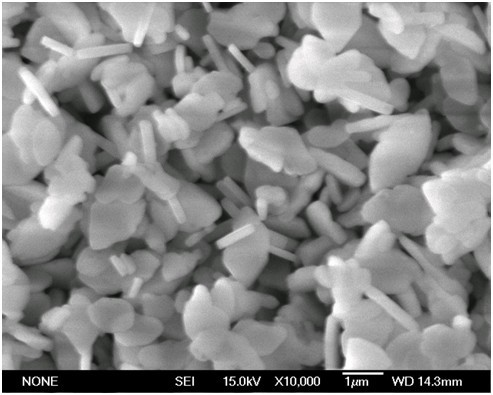

Image

Examples

Embodiment 1

[0018] [1] Take 10ml of 1.5mol / L LiOH solution, mix 0.5mol / L H 3 PO 4 10ml of the solution was slowly dropped into the LiOH solution dropwise, and fully stirred in an ice-water bath for 1 hour to obtain a white colloidal solution A.

[0019] [2] Another 0.5mol / L of Zn(Ac) 2 Solution 1ml, 0.01mol / L CuCl 2 Solution 1ml, 0.5mol / L polyethylene glycol solution 0.5ml, 1.5mol / L lithium hydroxide solution 1ml, mixed in an ice-water bath and continued to stir for 2 hours to obtain a white cloudy solution B.

[0020] [3] In the case of vigorous stirring, slowly add B solution to A, and continue to fully stir for 2 hours to form a mixed solution C.

[0021] [4] Take 0.5mol / L FeSO 4 Solution 10ml, the ferrous sulfate solution was quickly added to the mixed solution C, and stirred for 1min to form a dark green mixed solution D.

[0022] [5] After passing the mixed solution D into nitrogen, move it into the reaction kettle, react at 180°C for 16 hours, take samples after natural coolin...

Embodiment 2

[0024] The steps are the same as those in Example 1, except that the lithium source in [1] is LiCl.

Embodiment 3

[0026] The step is the same as that in Example 1, except that the lithium source in [1] is LiCH 3 COO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com