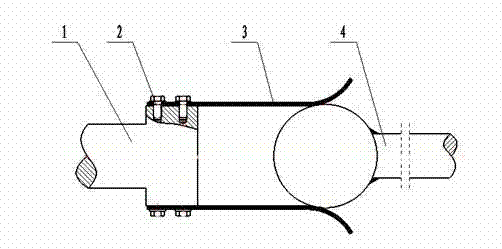

A kind of high-voltage isolating switch with touch finger function and its preparation method

A high-voltage isolating switch and contact finger technology, applied in electrical switches, air switch parts, contact meshing and other directions, can solve the problems of difficult heat dissipation, poor product quality, fatigue failure of parts, etc., to achieve high short-circuit current capacity, reduce The number of maintenance and the effect of improving the anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

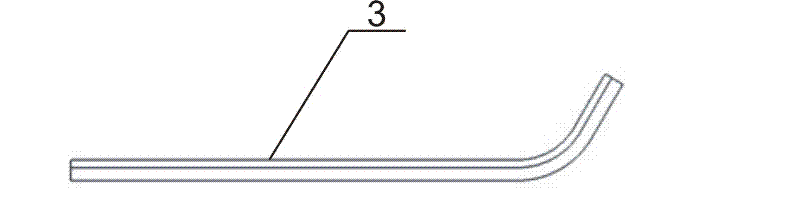

Embodiment 1

[0056] The CuCr alloy ingot purchased in the market is sawed and blanked, and then the billet is heated to 850°C in a box-type resistance furnace; the ingot is forged into a billet with a cross-section of 20×7mm; the billet is subjected to solution treatment at a temperature of 980°C ; Then carry out initial rolling, and roll the billet into a strip with a thickness of 3.5 mm; after the initial rolling, carry out aging treatment on the strip, the aging temperature is 450 ° C, the aging time is 6 hours, and the sample after aging is air-cooled; the strip is finished rolled Form a thin strip with a thickness of 3.0mm; saw the thin strip into a blank with a length of 180mm, and prepare a self-supporting contact finger part after composite forming by bending and pressing ribs and composite forming by bending and punching; the contact finger part is suitable for 10kV~500kV High voltage isolating switchgear.

Embodiment 2

[0058] The CuCr alloy ingot purchased in the market is sawed and cut, and then the billet is heated to 850°C in a box-type resistance furnace; the ingot is hot-rolled into a billet with a cross-section of 20×7mm; the billet is solidified at a temperature of 980°C treatment; then preliminary rolling is carried out, and the billet is rolled into a strip with a thickness of 3.5mm; after preliminary rolling, the strip is subjected to aging treatment, the aging temperature is 450°C, the aging time is 6h, and the sample after aging is air-cooled; the strip is subjected to A thin strip with a thickness of 3.0mm is prepared by drawing; the thin strip is cut into a blank with a length of 180mm by using a shearing die, and after composite forming by bending and embossing and composite forming by bending and punching, a self-supporting finger part is prepared; the new The finger parts are suitable for 10kV~500kV high voltage isolating switchgear.

Embodiment 3

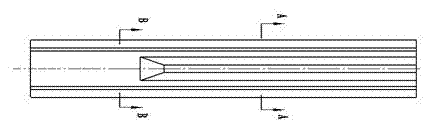

[0060] The composite forming of bending and embossed ribs according to the present invention adopts a special forming mold, including a lower die base b5, a screw 6, a die backing plate 7, a die 8, a guide post or a guide sleeve 9, an upper die base a10, a screw c11, a screw d12, mold handle 13, punch backing plate 14, punch fixing plate 15 and punch 16.

[0061] A die backing plate 7 is arranged between the upper die base c10 and the lower die base d5, and a punch 16 is arranged on the die base 7, and the punch 16 is connected with the upper die base a10 through a punch fixing plate 15.

[0062] The bending and punching composite forming of the present invention adopts a special forming mold, including a lower die base d17, a lower backing plate 18, a die backing plate 19, a punching punch fixing plate 20, a bending die 21, a die plate 22, and a guide post Or guide sleeve 23, punch 24, upper backing plate 25, upper die base c26, screw

[0063] e27, mold handle 28, punching r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com