A kind of anti-adhesive paper preparation method with well-tac-toe groove structure

A technology of anti-sticking paper and tic-tac-toe, which is applied in the field of light industry papermaking, can solve the problems of high manufacturing cost and large amount of silicone oil used for anti-sticking paper, and achieve the effects of reducing production costs, good anti-sticking performance, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Use a corona treatment machine to treat the surface of the backing paper of the release paper with a power of 600W for 100s.

[0029] (2) Mix polyethylene and isocyanate-modified polyethylene uniformly in a mass ratio of 1:0.1, first heat the bridge at a temperature of 180°C, then increase the temperature to 280°C, and apply a pressure of 10Mpa after melting It is extruded and kept at a temperature of about 320°C when laminating. After coating, the coated paper is obtained, and the coating amount is 10g / m 2 .

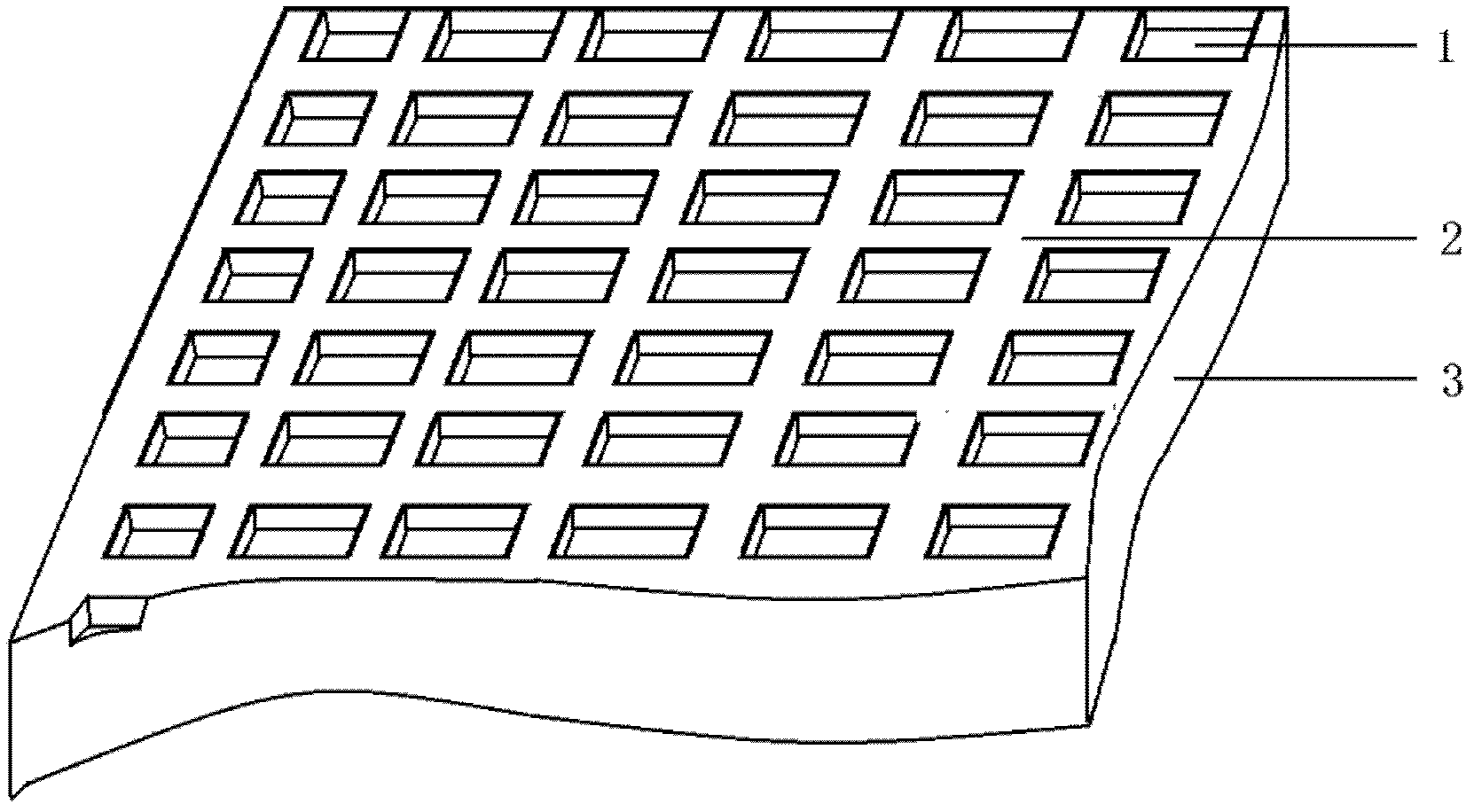

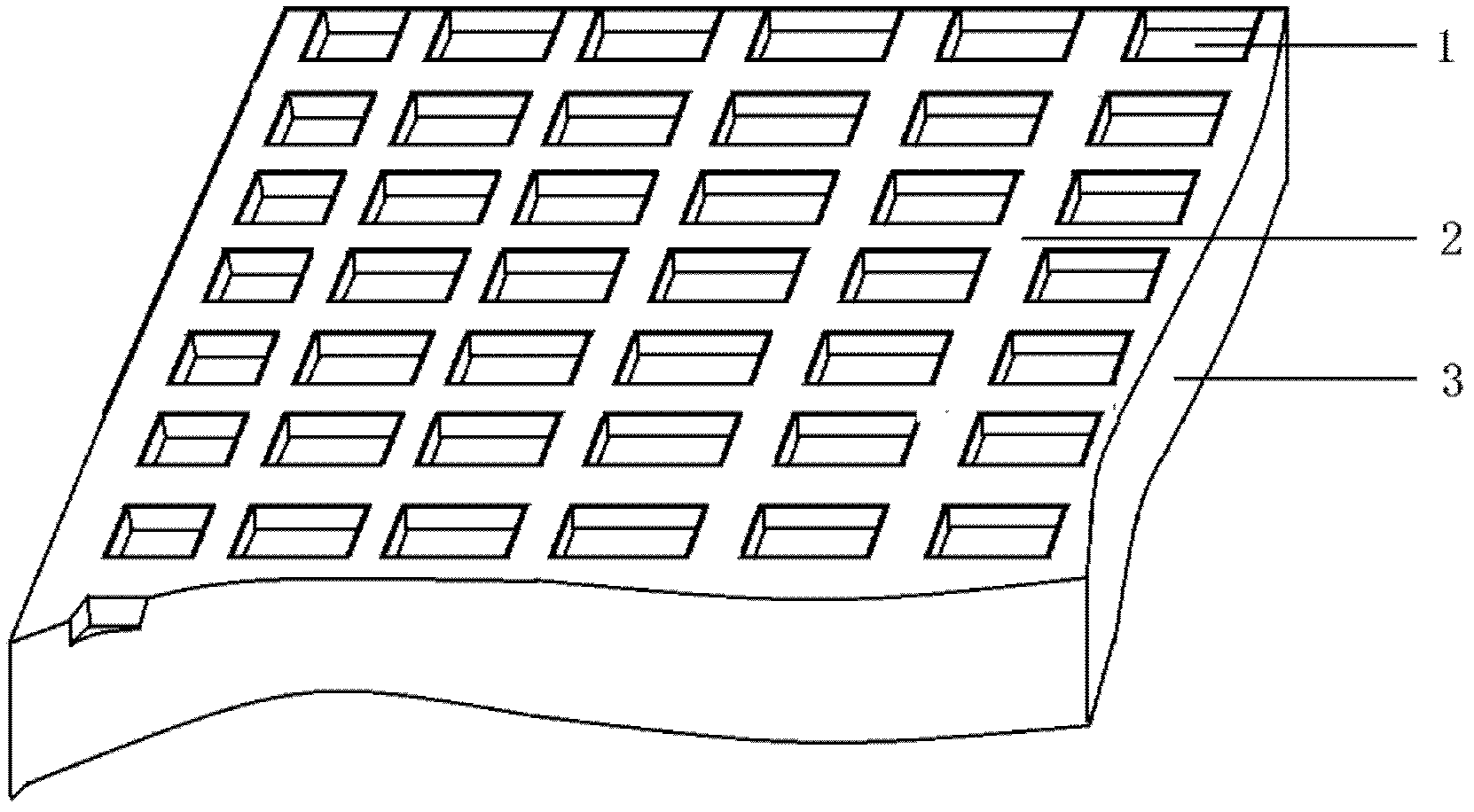

[0030] (3) The conveyor belt sends the coated paper to the roller with a convex module at a conveying speed of 60m / min for rolling.

[0031] After rolling, grooves appear on the surface of the coated paper. The size of the groove is 15mm×15mm, the depth of the groove is 1.8mm, and the width of the well-shaped side on the side is 12mm. Cool the fluted coated paper.

[0032] (4) Add methyl silicone oil to 1.0g / m 2 The amount of dry silicon coated evenly o...

Embodiment 2

[0035] (1) Use a corona treatment machine to treat the surface of the backing paper of the release paper with a power of 800W for 100s.

[0036] (2) Mix polyethylene and isocyanate-modified polypropylene evenly in a mass ratio of 1:0.2, first heat and bridge at a temperature of 250°C, then increase the temperature to 300°C, and apply a pressure of 20Mpa after melting It is extruded and kept at a temperature of about 380°C when laminating. After coating, the coated paper is obtained, and the coating amount is 6g / m 2 .

[0037] (3) The conveyor belt sends the coated paper to the rollers with convex modules at a conveying speed of 100m / min for rolling.

[0038] After rolling, grooves appear on the surface of the coated paper. The size of the groove is 15mm×15mm, the depth of the groove is 0.6mm, and the width of the well-shaped side of the side is 10mm. Cool the fluted coated paper.

[0039] (4) Add methyl hydrogen silicone oil at 1.5g / m 2 The amount of dry silicon coated e...

Embodiment 3

[0042] (1) Use a corona treatment machine to treat the surface of the backing paper of the release paper with a power of 800W for 100s.

[0043] (2) Mix polyethylene and isocyanate-modified polyethylene evenly in a mass ratio of 1:0.15, first heat the bridge at a temperature of 200°C, then increase the temperature to 350°C, and apply a pressure of 16Mpa after melting It is extruded and kept at a temperature of about 330°C during coating. After coating, the coated paper is obtained. The amount of coating is 20g / m 2 .

[0044] (3) The conveyor belt sends the coated paper to the rollers with convex modules at a conveying speed of 80m / min for rolling.

[0045] After rolling, grooves appear on the surface of the coated paper. The size of the groove is 15mm×15mm, the depth of the concave-convex groove is 1.5mm, and the width of the well-shaped side on the side is 11mm. Cool the fluted coated paper.

[0046] (4) Add methyl vinyl silicone oil at 2g / m 2 The amount of dry silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com