Preparation method and device of a nanofiber composite light-transmitting material

A technology of light-transmitting materials and nanofibers, which is applied in fiber processing, conjugated synthetic polymer rayon, non-woven fabrics, etc., can solve the problems of low reinforcing fiber content, complex parameters, unstable process, etc. The effect of enhanced tensile mechanical properties, undisturbed light transmission, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

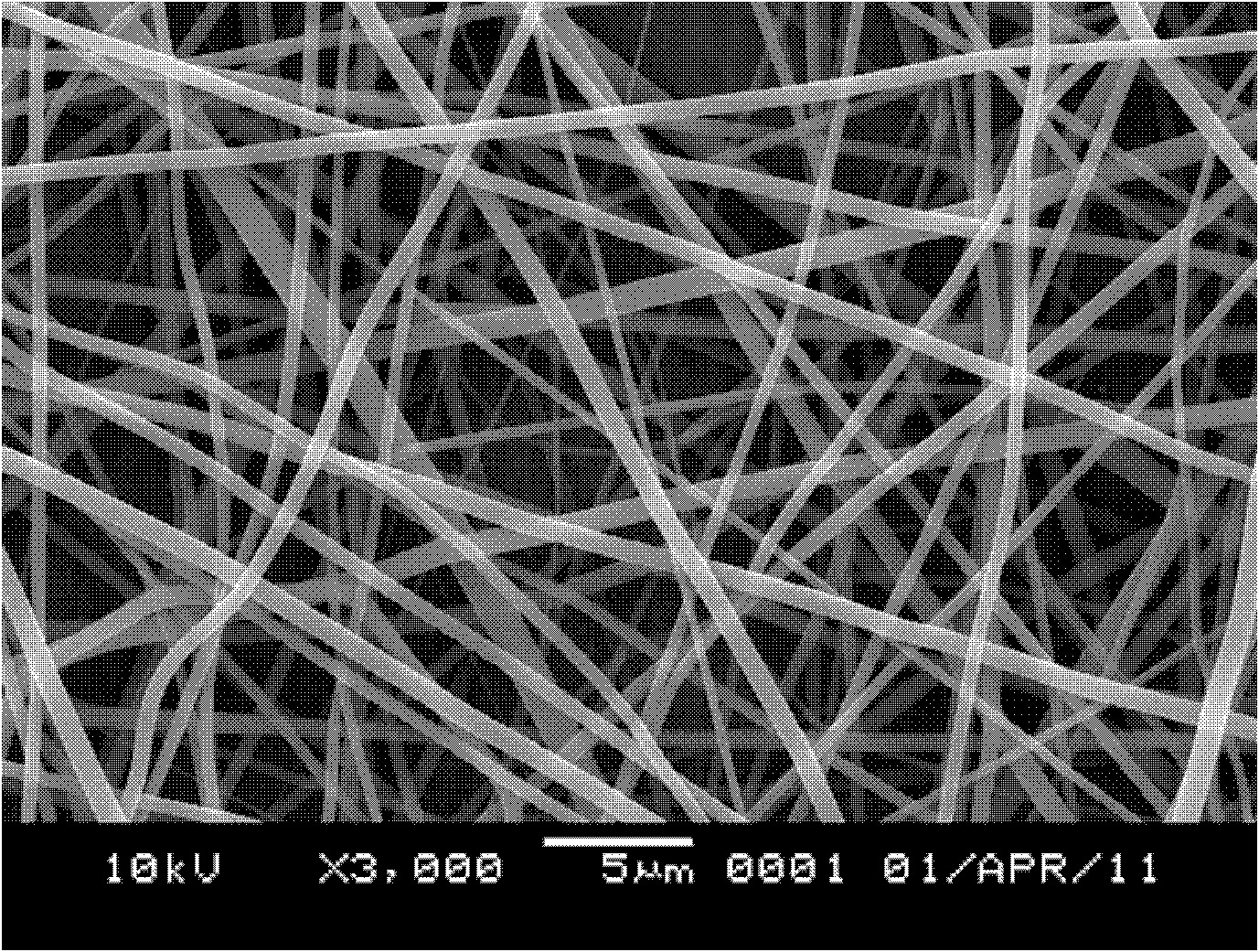

Image

Examples

Embodiment l

[0026] Weigh 0.8g of PA-6 and 4g of PMMA with an electronic analytical balance and dissolve them in 10g and 16g of trifluoroethanol respectively, stir for 24h until completely dissolved, and obtain PA-6 enhancements with a concentration of 8% (solute gram / solvent gram) respectively. Fibrous material spinning solution and 25% (solute gram / solvent gram) PMMA light-transmitting matrix material spinning solution.

[0027] Such as figure 1 Shown is a schematic diagram of a uniform blending device. Spinnerets 2 are installed on the left and right sides of the receiving drum 1, and the supply rates of the spinning light-transmitting matrix material and the reinforcing material stock solution are respectively controlled by a micro-injection pump 3. A voltage is applied between the receiving drums 1 through a high-voltage power supply 4, a stable jet is formed between the spinneret 2 and the receiving drum 1, and the left reinforcing material spinneret 2 is reciprocated to collect the...

Embodiment 2

[0029] Weigh 3g PA-6 and 3g PMMA with an electronic analytical balance and dissolve them in 20g and 10g of trifluoroethanol respectively, stir for 24h until completely dissolved, and obtain PA-6 reinforcing fibers with a concentration of 15% (solute gram / solvent gram) respectively Material spinning solution and 30% (solute gram / solvent gram) PMMA light-transmitting matrix material spinning solution.

[0030]The conditions for uniform blending are as follows: the voltage of the transparent base material is 1 kV, the electric field or receiving distance is 2 cm, the diameter of the spinneret is 1 μm, and the supply rate of spinning dope is 0.1 mL / h; the voltage of the reinforcing material is 20 kV, and the electric field or receiving distance is 4cm, the diameter of the spinneret is 1.2μm, the supply rate of PA-6 spinning solution is 0.2mL / h; the rotation speed of the drum collection device is 1rpm, the ambient temperature is 20°C, and the relative humidity of the environment is ...

Embodiment 3

[0032] Weigh 1g PA-6 and 3g PMMA with an electronic analytical balance and dissolve them in 10g and 10g of trifluoroethanol respectively, stir for 24h until completely dissolved, and obtain PA-6 reinforcing fibers with a concentration of 10% (solute gram / solvent gram) respectively Material spinning solution and 30% (solute gram / solvent gram) PMMA light-transmitting matrix material spinning solution.

[0033] The conditions for uniform blending are as follows: the voltage of the transparent base material is 100kV, the electric field or receiving distance is 50cm, the diameter of the spinneret is 0.1mm, and the supply rate of spinning dope is 20mL / h; the voltage of the reinforcing material is 80kV, and the electric field or receiving distance is 60cm, the spinneret diameter is 0.2mm, the supply rate of PA-6 spinning dope is 18mL / h; the rotating speed of the drum collection device is 10000rpm, the ambient temperature is 60°C, and the relative humidity of the environment is 80%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com