Manufacturing process of smooth roughened electrolytic copper foil

A manufacturing process, electrolytic copper foil technology, applied in the field of copper foil manufacturing, can solve the problems of increasing the complexity of copper foil process, product short circuit, open circuit, and increasing processing cost, so as to shorten the production process, reduce short circuit and open circuit rate, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

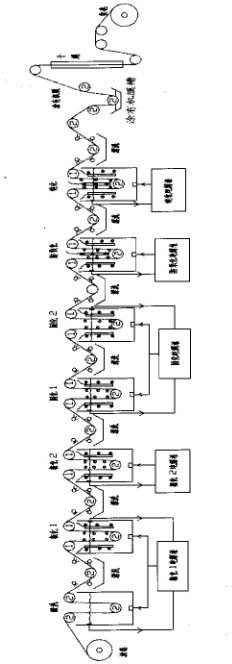

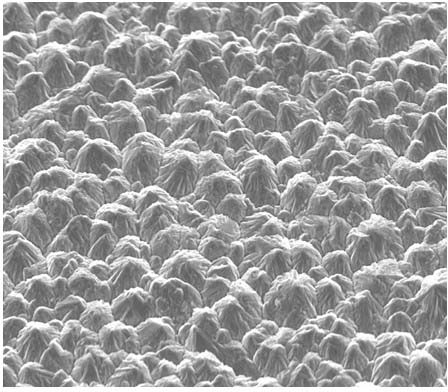

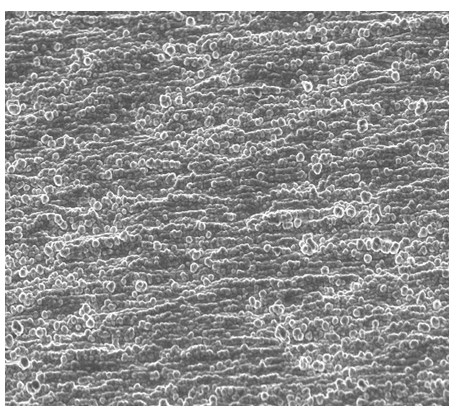

[0020] See figure 1 The first embodiment of the present invention provides the manufacturing process of the roughened electrolytic copper foil (that is, the manufacturing method of the roughened electronic copper foil) is obtained by changing the normal surface treatment method and process of copper foil. The smooth surface is roughened. The production method is to pass the raw foil (unsurface-treated electrolytic copper foil) through the surface treatment equipment, and go through the pickling process, the first step of smoothing, the second step of smoothing, and the smoothing. The first step of curing, the second step of smooth curing, the double-sided anti-oxidation step, the double-sided passivation step, and the smooth coating of coupling agent are completed in a total of eight steps, all of which are concentrated in one surface treatment equipment. The manufacturing method of smooth roughening electronic copper foil uses the raw foil of conventional high-precision electro...

no. 2 approach

[0034] Refer to the manufacturing method of Example 1 to prepare copper foil products. The manufacturing method of the glossy roughened electronic copper foil provided by the second embodiment of the present invention is obtained by changing the normal surface treatment method and process of copper foil. The surface is roughened. The production method is to pass the raw foil (unsurface-treated electrolytic copper foil) through the surface treatment equipment, and go through the pickling process, the first process of smoothing the surface, the second process of smoothing the surface, and the curing of the smooth surface. The first process, the second process of smooth curing, the double-sided anti-oxidation process, the double-sided passivation process, and the smooth coating of coupling agent process are completed in a total of eight consecutive processes, all of which are concentrated in one surface treatment equipment. The manufacturing method of smooth roughening electronic c...

no. 3 approach

[0047] Refer to the manufacturing method of Example 1 to prepare copper foil products. The third embodiment of the present invention provides a method for manufacturing a roughened electronic copper foil by changing the normal surface treatment method and process of copper foil. The surface is roughened. The production method is to pass the raw foil (unsurface-treated electrolytic copper foil) through the surface treatment equipment, and go through the pickling process, the first process of smoothing the surface, the second process of smoothing the surface, and the curing of the smooth surface. The first process, the second process of smooth curing, the double-sided anti-oxidation process, the double-sided passivation process, and the smooth coating of coupling agent process are completed in a total of eight consecutive processes, all of which are concentrated in one surface treatment equipment. The manufacturing method of smooth roughening electronic copper foil uses the raw fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com