Biological column leaching device

A column leaching and biological technology, applied in the direction of improving process efficiency, etc., can solve the problems of low equipment processing capacity, high production cost of leaching, low requirements and low utilization, etc., to achieve increased solid-liquid contact area and simple structure , Improve the effect of growth and metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

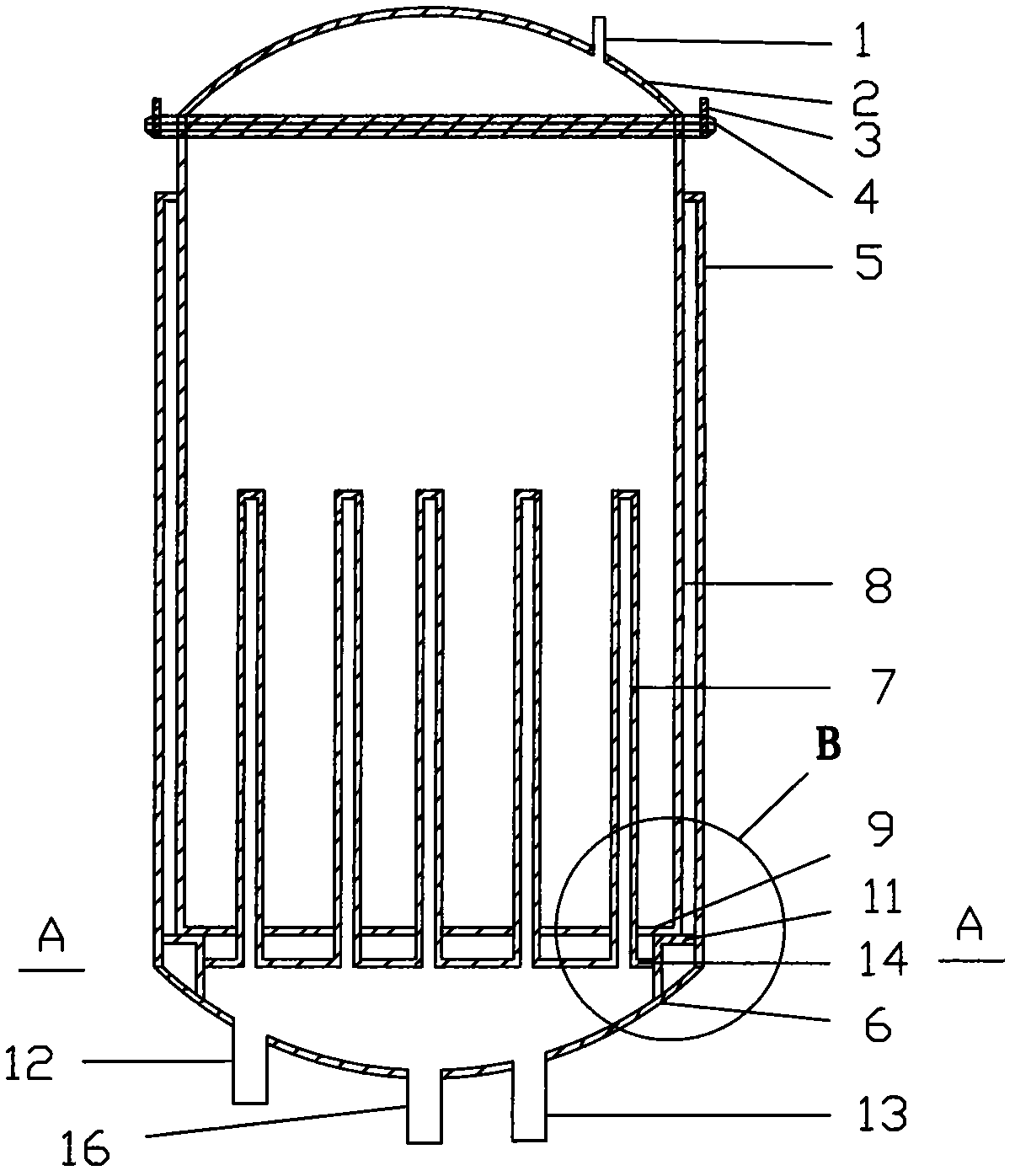

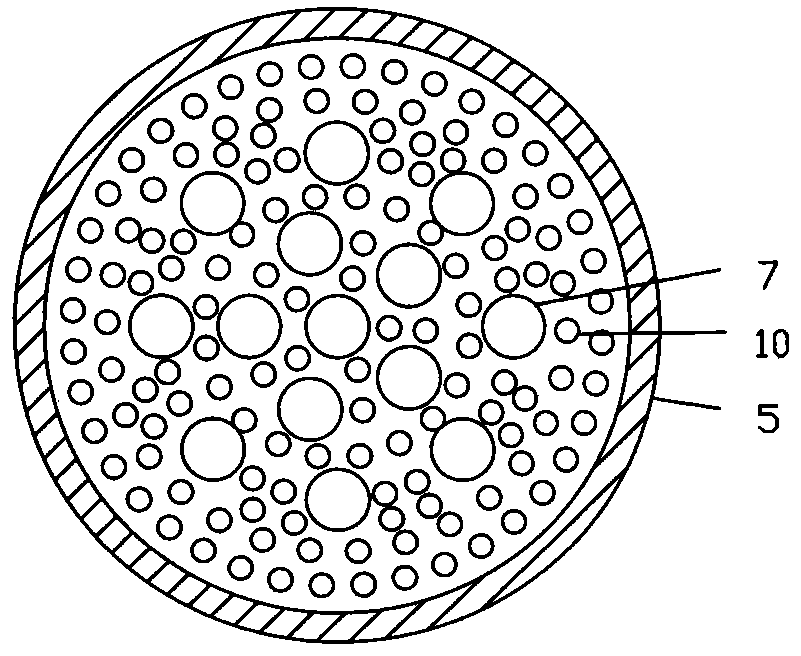

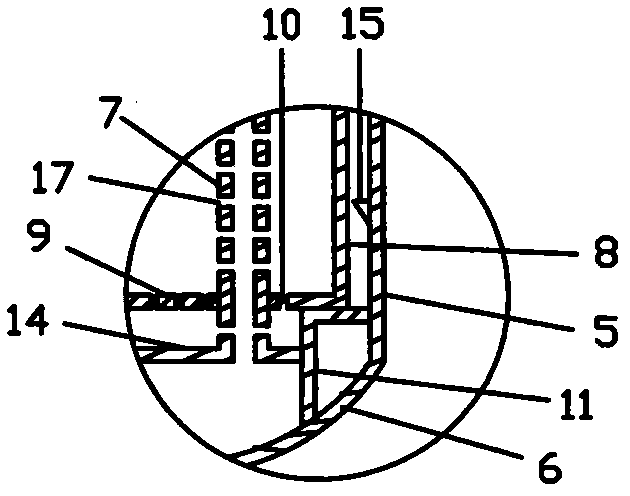

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , The present invention is suitable for bioleaching of various metals in biometallurgy. The device includes three main parts, an outer jacket 5 , an inner cylinder 8 and a cylindrical ventilation pipe 7 .

[0022] The outer jacket 5 is cylindrical, the bottom of the outer jacket 5 is a spherical bottom 6, and the lower part of the spherical bottom 6 has a circular sampling port 12, an air inlet 13, and a discharge port 16. The top of the outer jacket 5 and the inner cylinder 8 There is a sealing ring at the contact point, the inner cylinder 8 can slide up and down along the outer jacket 5, the upper part of the spherical bottom 6 has a support 11, the support 11 is used to support the inner cylinder 8 before the first lifting, and the support 11 is installed There is a fixed base plate 14, the base plate 14 has a vent hole, the vent hole is provided with a cylindrical vent pipe 7, the top of the cylindrical vent pipe 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com