A kind of environment-friendly high-solid varnish and preparation method thereof

A high-solids, environmentally friendly technology, applied in coatings and other directions, can solve the problems of low solids, air pollution, and low varnish fullness, and achieve the effects of solving inventory pressure, improving fullness, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

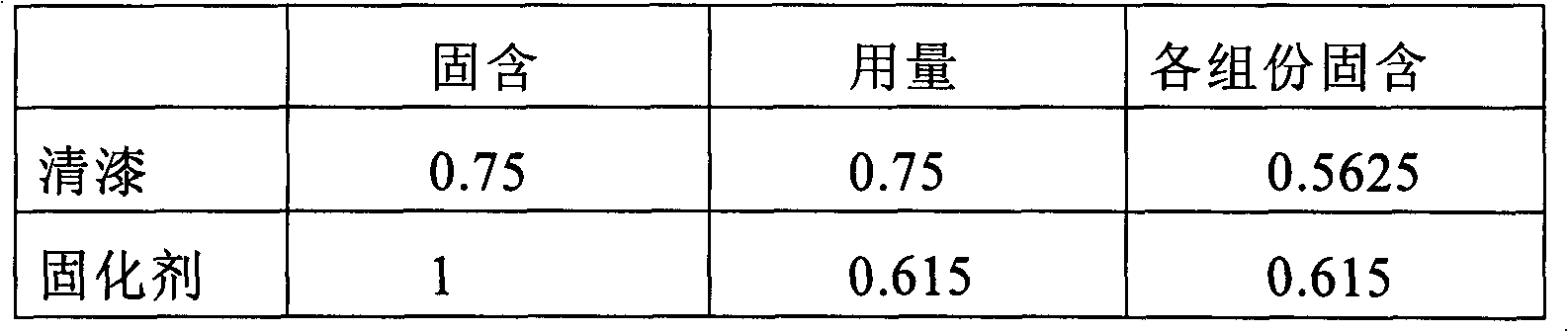

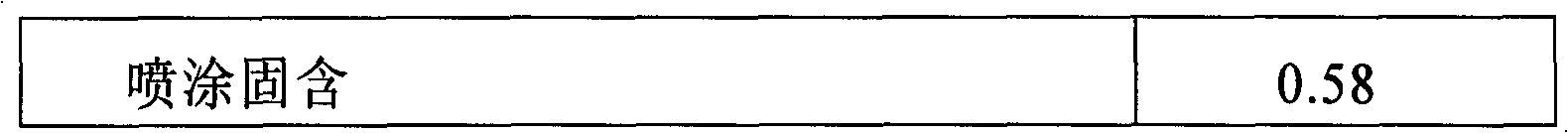

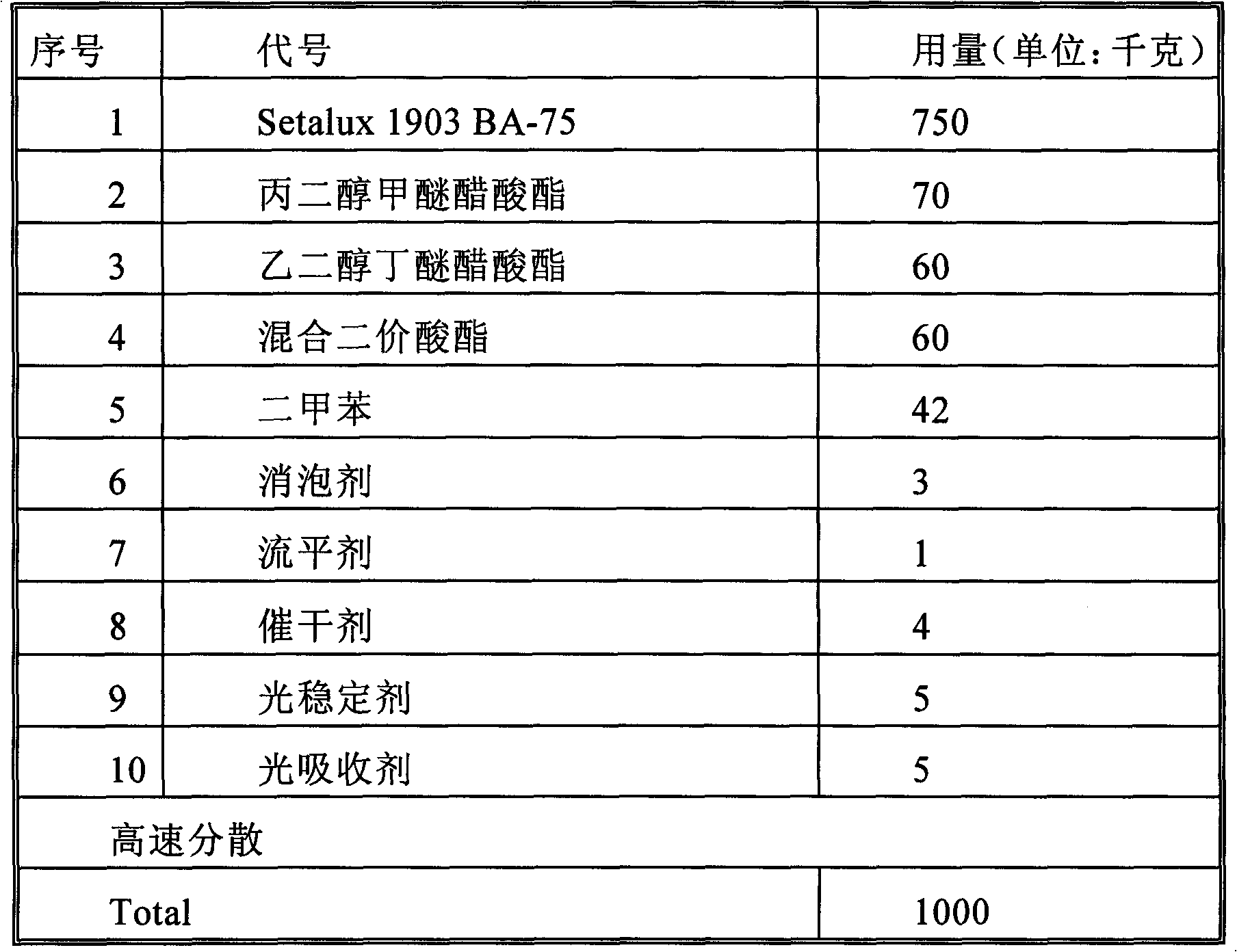

[0039] Component A

[0040]

[0041] Add resin, solvent a, defoamer, leveling agent, drier, light stabilizer, and light absorber into the tank according to the formula requirements, stir at a speed of 800-1200 rpm on a high-speed disperser, and keep the temperature at 30-45°C, the time is 20-30 minutes, check the cleanliness of the varnish, there are no obvious particles, the viscosity is tested with 4 cups, adjusted to the range of 60-90 seconds, and filtered to obtain component A.

[0042] Component B

[0043]

[0044]

[0045] According to the formula requirements, add the purchased curing agent and solvent b into the tank, stir on a high-speed disperser at a speed of 800-1200 rpm, keep the temperature at 30-45°C, and take 20-30 minutes to prepare the curing agent. Check the cleanliness of the curing agent, if there are no obvious particles, filter to obtain component B.

[0046] Mix components A and B in a volume ratio of 2:1 to obtain an environmentally friendl...

Embodiment 2

[0048] Component A

[0049]

[0050] Add resin, solvent a, defoamer, leveling agent, drier, light stabilizer, and light absorber into the tank according to the formula requirements, stir at a speed of 800-1200 rpm on a high-speed disperser, and keep the temperature at 30-45°C, the time is 20-30 minutes, check the cleanliness of the varnish, there are no obvious particles, the viscosity is tested with 4 cups, adjusted to the range of 60-90 seconds, and filtered to obtain component A.

[0051] Component B

[0052]

[0053] According to the formula requirements, add the purchased curing agent and solvent b into the tank, stir on a high-speed disperser at a speed of 800-1200 rpm, keep the temperature at 30-45°C, and take 20-30 minutes to prepare the curing agent. Check the cleanliness of the curing agent, if there are no obvious particles, filter to obtain component B.

[0054] Mix components A and B in a volume ratio of 2:1 to obtain an environmentally friendly high-solid...

Embodiment 3

[0056] Component A

[0057]

[0058]

[0059] Add resin, solvent a, defoamer, leveling agent, drier, light stabilizer, and light absorber into the tank according to the formula requirements, stir at a speed of 800-1200 rpm on a high-speed disperser, and keep the temperature at 30-45°C, the time is 20-30 minutes, check the cleanliness of the varnish, there are no obvious particles, the viscosity is tested with 4 cups, adjusted to the range of 60-90 seconds, and filtered to obtain component A.

[0060] Component B

[0061]

[0062] According to the formula requirements, add the purchased curing agent and solvent b into the tank, stir on a high-speed disperser at a speed of 800-1200 rpm, keep the temperature at 30-45°C, and take 20-30 minutes to prepare the curing agent. Check the cleanliness of the curing agent, if there are no obvious particles, filter to obtain component B.

[0063] Mix components A and B in a volume ratio of 2:1 to obtain an environmentally friendl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com