Device and method for foam separation of polysaccharides in Polyporus polysaccharide extract

A technology for foam separation and polysaccharide polysaccharide, which is applied in the chemical industry and can solve the problems of large consumption of ethanol and increased energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments.

[0014] 1. Extraction of Polyporus polysaccharide

[0015] After drying and pulverizing the Polyporus polysaccharides, the Polyporus polysaccharides were extracted according to the extraction time of 5 minutes, temperature of 75°C, solid-liquid ratio (solid material: distilled water) 1:20 (g / ml), pH=9, and microwave power of 400W; The mixture was centrifuged to remove the residue, and the extract was used for later use.

[0016] 2. Preparation of crude polysaccharide

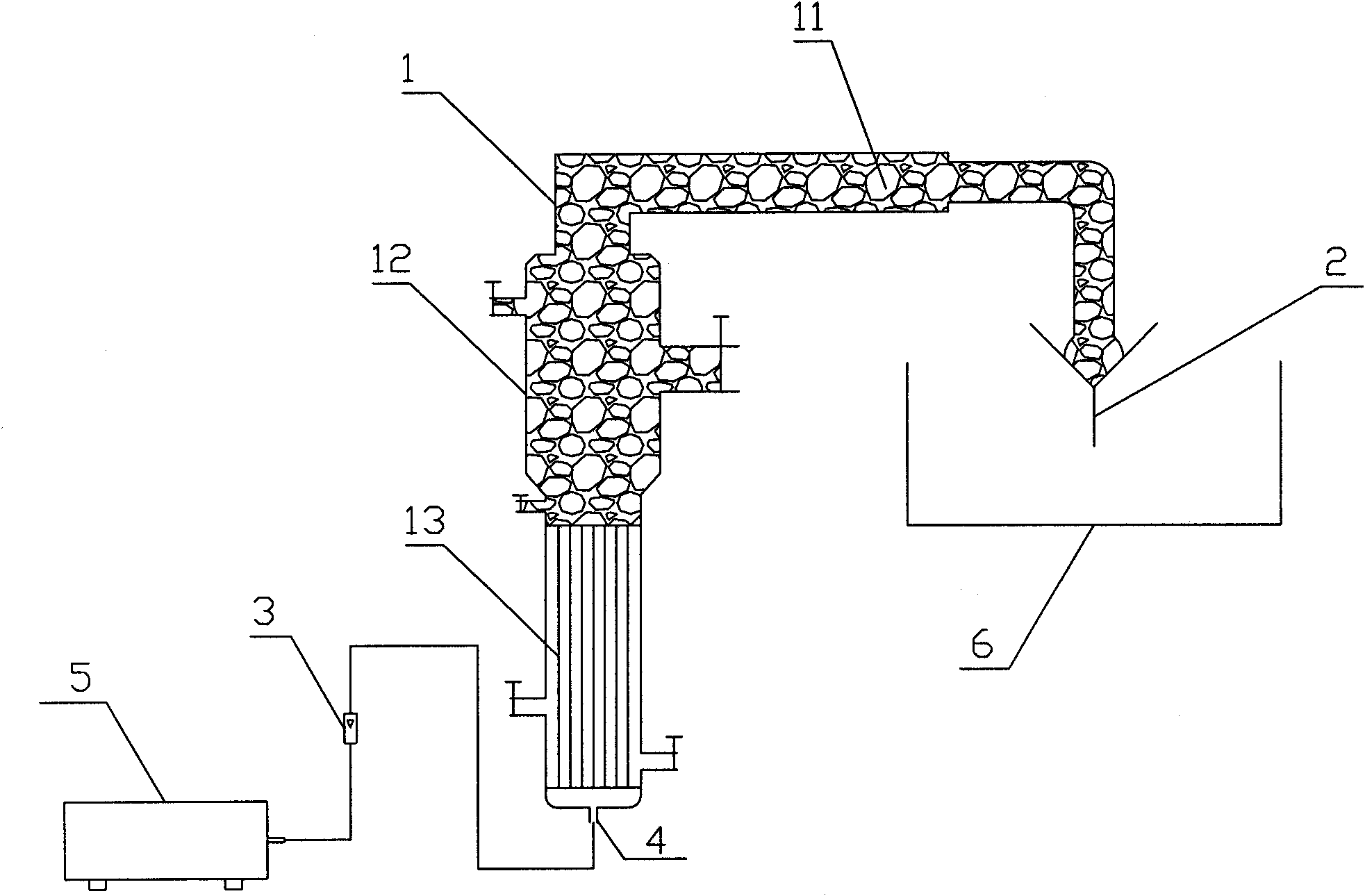

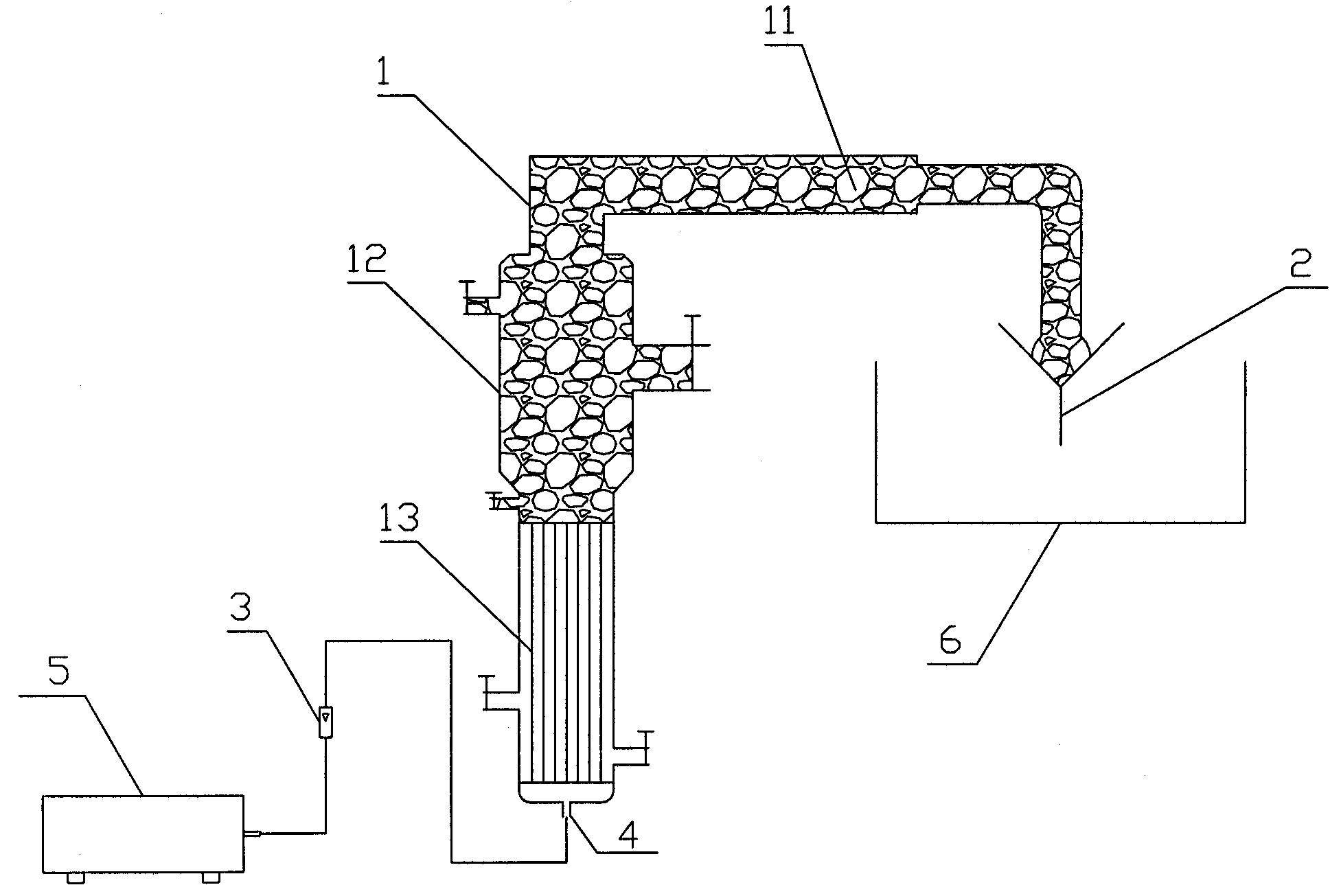

[0017] The present invention adopts the intermittent foam separation method to separate polysaccharides in the extract, and the device includes a foam separation tower 1, an air supply system (comprising an air compressor 5 and a rotameter 3), and a foam collector 2.

[0018] Foam separation tower 1 can adopt internal diameter to be 0.12m, the plexiglass column of height 1.3m;

[0019] The foam separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com