A method for preparing self-substrated sno2 nanorod arrays

A nanorod array and substrate technology, applied in the field of semiconductor nanomaterial preparation, can solve the problems of ineffective contact between the array and the substrate, inability to achieve miniaturized construction, complicated preparation process, etc., and achieve excellent gas-resistance sensitivity performance and equipment requirements. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh a certain amount of SnCl 4 ·5H 2 Stir O (0.1M), NaOH (1M) until dissolved in 10mL deionized water, weigh the surfactant sodium dodecyl sulfate (SDS) 0.33M, dissolve it with 20mL n-heptane and 5mL n-pentanol Basic Sn 4+ The solution is mixed into a uniform white microemulsion system. Stir for 30 minutes to make SnO 2 Nanocrystals nucleate and self-assemble into SnO with the assistance of the system 2 thin layer substrate;

[0027] The above system was transferred to a 50mL polytetrafluoroethylene hydrothermal reaction kettle, and hydrothermally reacted at 220°C for 24 hours; due to the SnO 2 Anisotropy of crystal growth, growing as vertically aligned arrays of nanorods on the substrate. After the reaction was completed, it was naturally cooled to room temperature, washed and filtered with deionized water and ethanol, and dried to obtain a white powder.

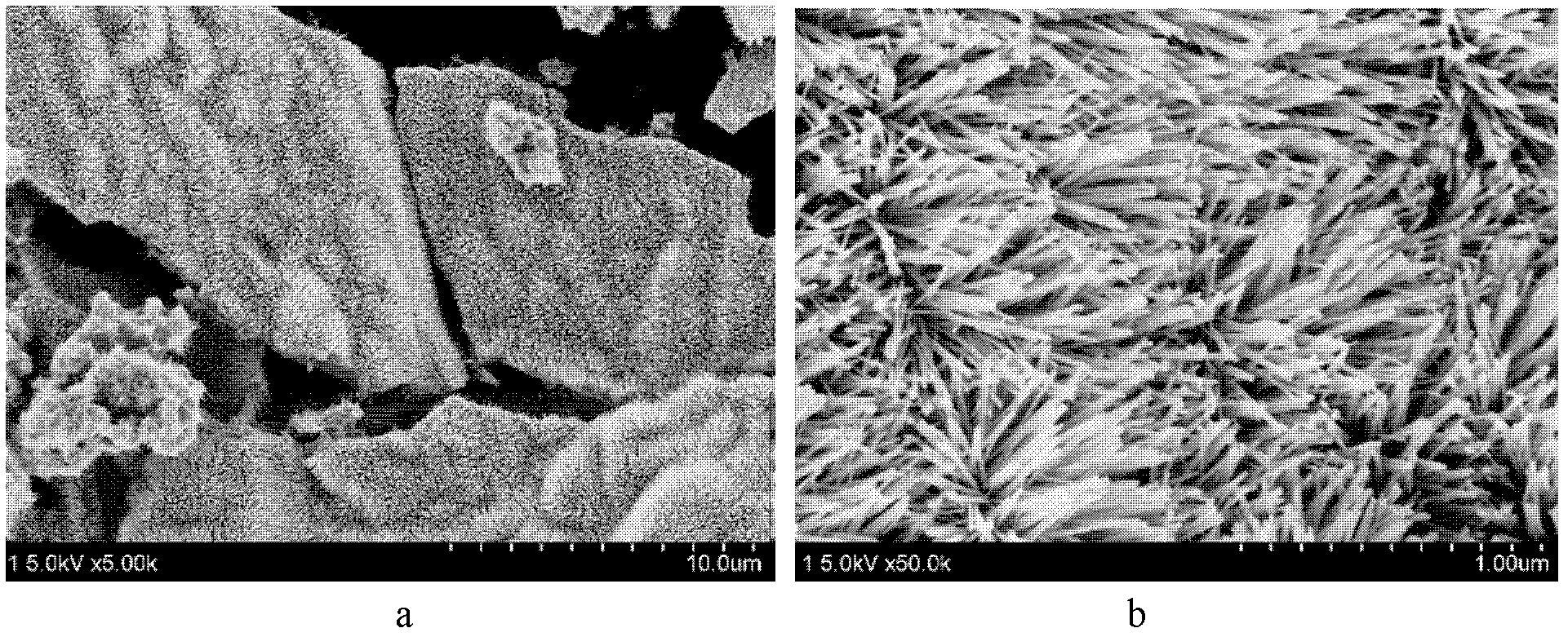

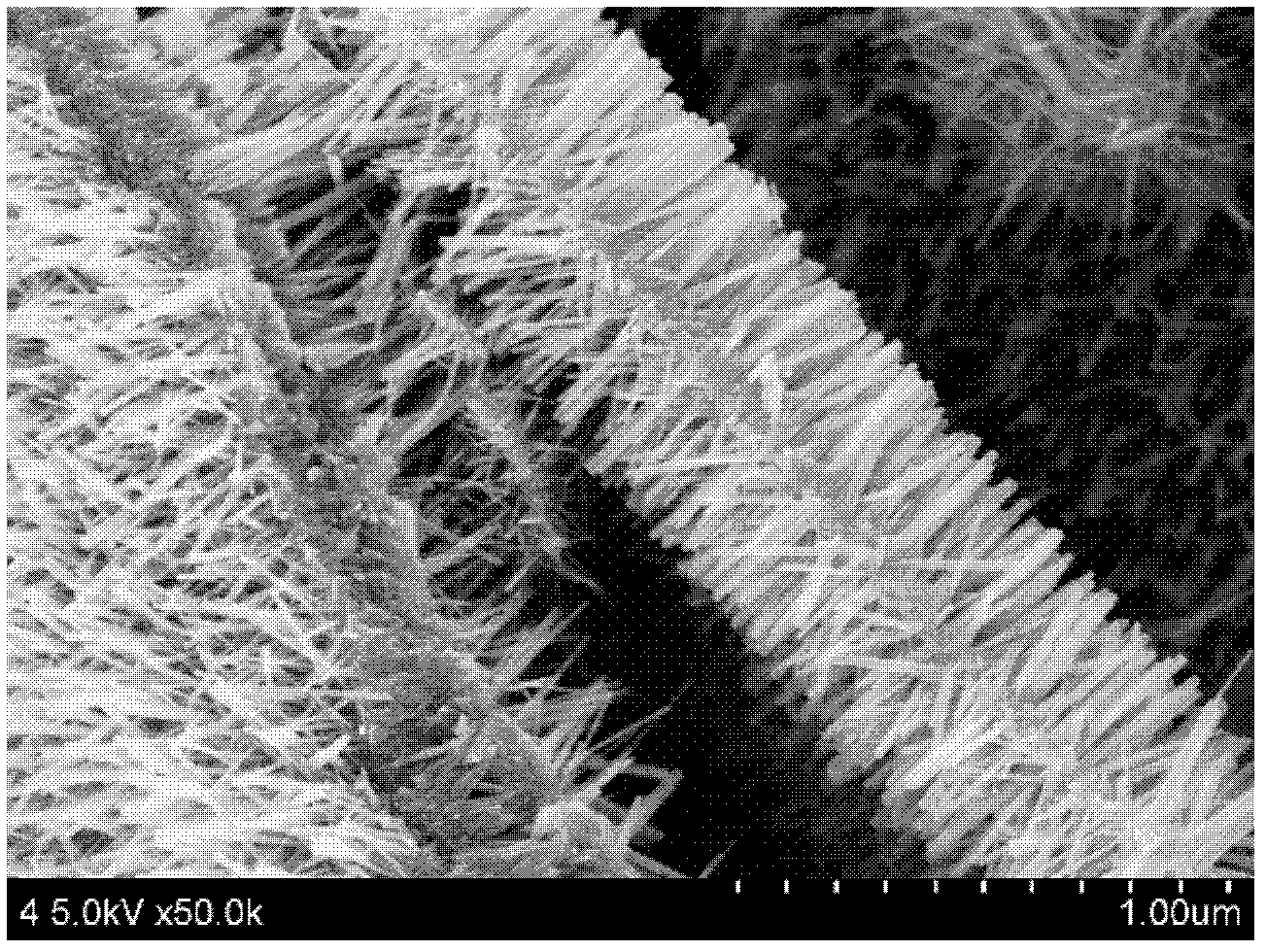

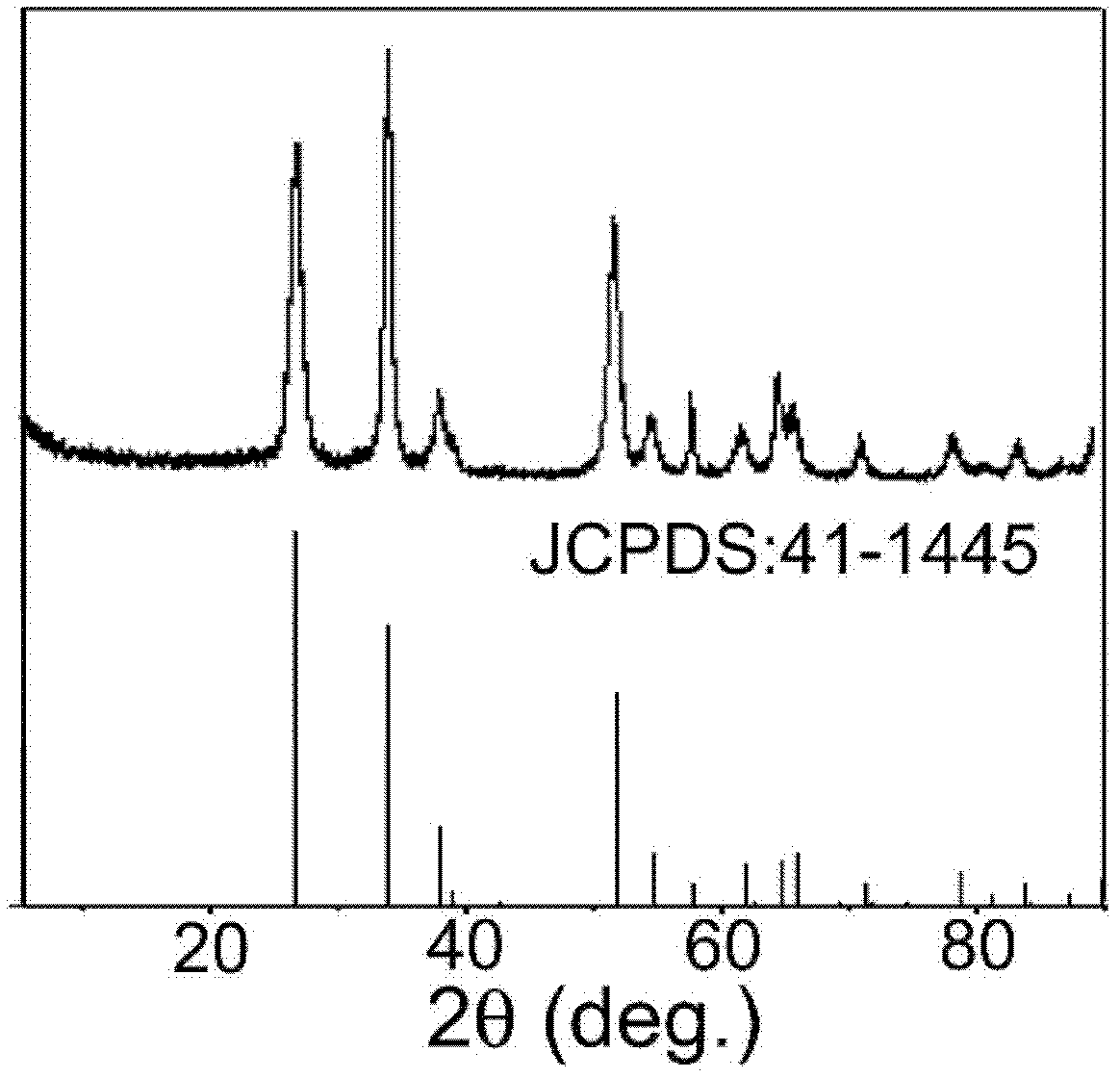

[0028] The scanning electron microscope (SEM) photos of the obtained sample surface are as follows: figu...

Embodiment 2

[0032] Weigh a certain amount of SnCl 4 ·5H 2Stir O (0.1M), NaOH (1M) until dissolved in 10mL deionized water, weigh the surfactant sodium dodecyl sulfate (SDS) 0.33M, dissolve it with 20mL n-heptane and 5mL n-pentanol Basic Sn 4+ The solution is mixed into a uniform white microemulsion system.

[0033] After stirring for 30 minutes, the obtained system was transferred to a 50 mL polytetrafluoroethylene hydrothermal reaction vessel, and subjected to a hydrothermal reaction at 220° C. for 6 hours, and grew into a vertically aligned nanorod array on the substrate. After the reaction was completed, it was naturally cooled to room temperature, the white precipitate was washed and filtered with deionized water and ethanol, and a white powder was obtained after drying.

[0034] Scanning electron microscopy (SEM) tests confirmed the growth of SnO 2 The nanorods are shorter in length, only 200nm arrays.

Embodiment 3

[0036] Weigh a certain amount of SnCl 4 ·5H 2 O (0.1M), NaOH (1M) were stirred until they were dissolved in 10mL of deionized water, and the surfactant sodium dodecyl sulfate (SDS) 0.16M was weighed, and dissolved with 20mL of n-heptane and 5mL of n-pentanol. Basic Sn 4+ The solution is mixed into a uniform white microemulsion system. Stir for 30 minutes to make SnO 2 Nanocrystals nucleate and self-assemble into SnO with the assistance of the system 2 Thin base.

[0037] The above system was transferred to a 50 mL polytetrafluoroethylene hydrothermal reaction kettle, and hydrothermally reacted at 220° C. for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, washed and filtered with deionized water and ethanol, and dried to obtain a white powder.

[0038] Scanning electron microscopy (SEM) tests confirmed that the array's several nanorod heads were bonded together. This shows that the reduction of the amount of surfactant SDS makes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com