Preparation method of nano SAPO-31 molecular sieve

A technology of SAPO-31 and molecular sieve, which is applied in the field of preparation of SAPO-31 molecular sieve, can solve problems such as miscellaneous crystals in products, and achieve the effects of shortening crystallization time, improving selectivity, and high acid site density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

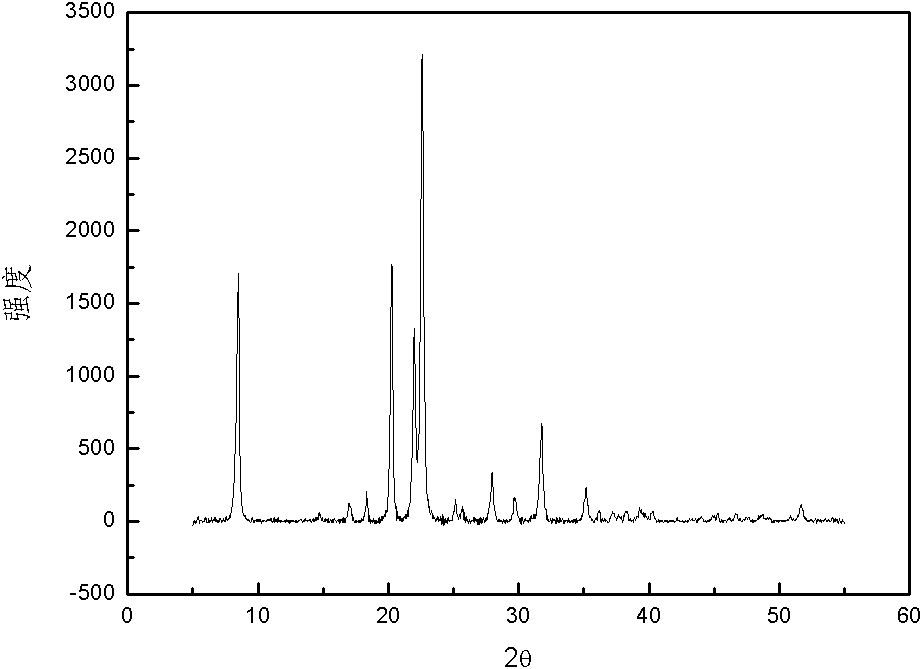

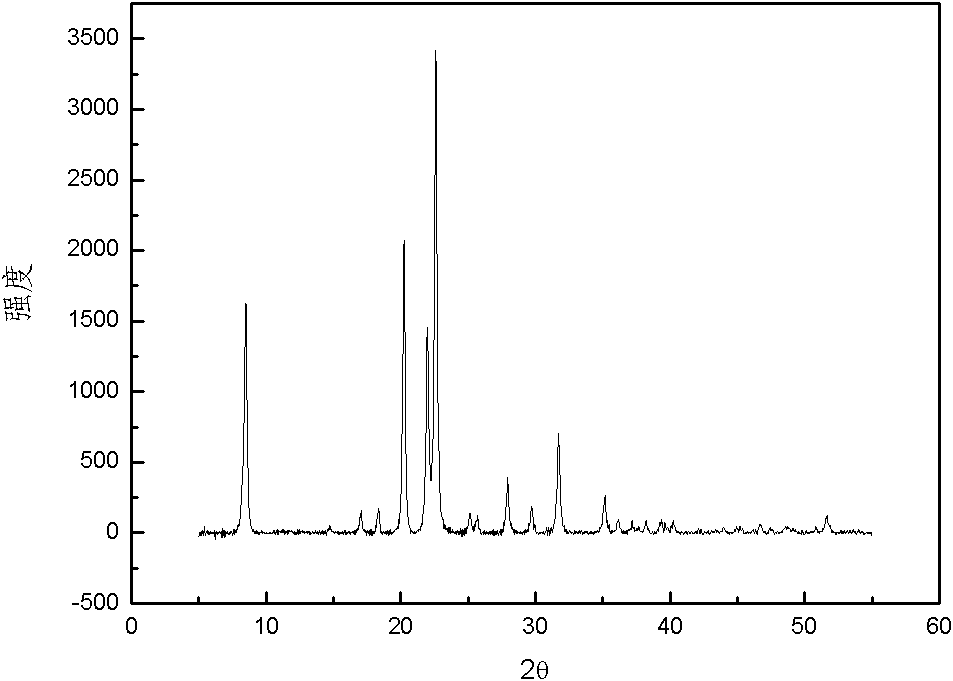

Image

Examples

specific Embodiment approach 1

[0007] Specific embodiment one: This embodiment provides a kind of preparation method of pure phase nanometer SAPO-31 molecular sieve, specifically is finished according to the following steps:

[0008] 1. Preparation of the initial gel: Phosphoric acid solution with a mass fraction of 85%, aluminum isopropoxide with a mass fraction of 24.8%, fumed silica (Cab-O-Sil M-5), and dioxane with a mass fraction of 98.3% Add n-butylamine and HF solution with a mass fraction of 40% into deionized water in sequence, and stir fully at 400-1000r / min for 0.5-3h to obtain the initial gel; 2. Forming: the initial gel prepared in step 1 Place the glue in a crystallization kettle, crystallize at 130-200°C for 3-36 hours, then cool to room temperature, and put the crystallized product in a drying oven after centrifugal filtration and washing, and dry at 100°C-200°C 8h to 36h, put the dried crystallized product in a muffle furnace, and roast at 500-650°C for 2h-8h to obtain nano-SAPO-31 molecula...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass fraction of the phosphoric acid solution added in step one is 85% and the mass fraction is 24.8% aluminum isopropoxide mass ratio is 1:( 16~1.9), the mass fraction of the added mass fraction is 85% phosphoric acid solution and the mass ratio of fumed silica (Cab-O-Sil M-5) is 1:(0.05~0.28), the mass fraction of the added The mass ratio of 85% phosphoric acid solution to 98.3% di-n-butylamine is 1:(0.7~0.9), and the added mass fraction is 85% phosphoric acid solution and 40% HF solution The mass ratio of the added phosphoric acid solution with a mass fraction of 85% and deionized water is 1:(3.2~4). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and one of specific embodiments one to two is: the mass fraction of the phosphoric acid solution added in step 1 is 85% and the mass ratio of aluminum isopropoxide of 24.8% is 1:1.8, the added mass fraction is 85% phosphoric acid solution and the mass ratio of fumed silica (Cab-O-Sil M-5) is 1:0.15, the added mass fraction is 85% phosphoric acid Solution and mass fraction are that the mass ratio of the di-n-butylamine of 98.3% is 1:0.8, and the mass fraction of adding is that the mass ratio of the phosphoric acid solution of 85% and the HF solution of 40% is 1:0.02, so The mass ratio of the added phosphoric acid solution with a mass fraction of 85% to deionized water is 1:3.5. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com