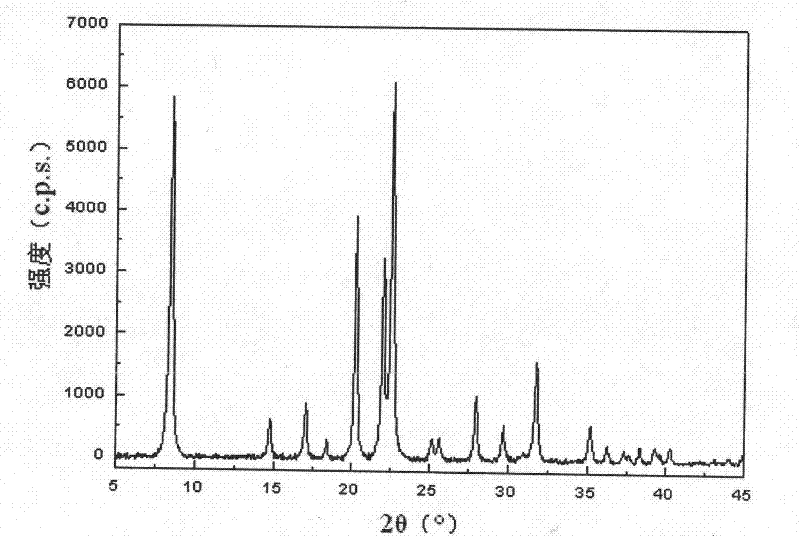

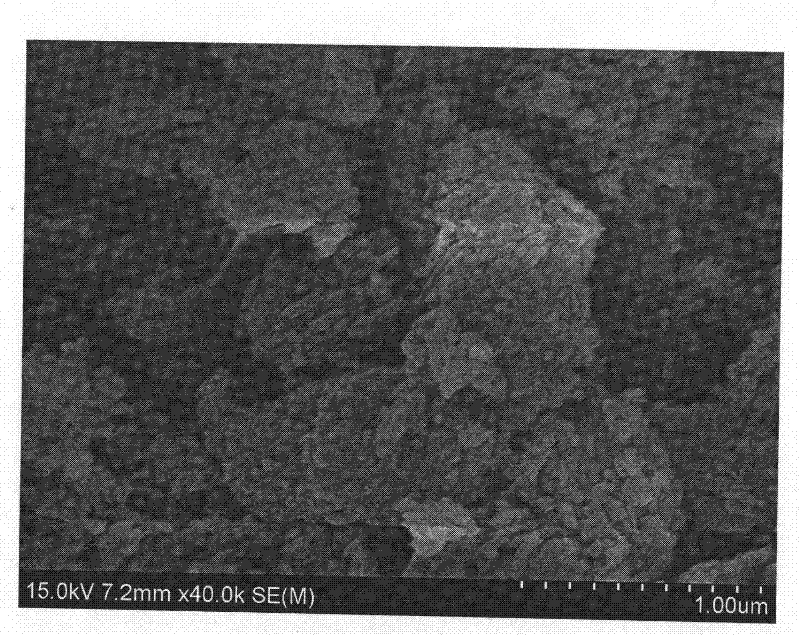

Method for synthesizing SAPO-31 molecular sieves through microwave heating

A technology of SAPO-31 and microwave heating, which is applied in the field of preparation of SAPO-31 molecular sieve, can solve the problems of long crystallization time, expensive templating agent, miscellaneous crystals in the product, etc., and achieve shortened crystallization time and controllable acidity Strong, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] The specific embodiment one: a kind of microwave heating synthesis method of SAPO-31 molecular sieve of the present embodiment is carried out according to the following steps: one, by phosphoric acid: water: di-n-butylamine: aluminum isopropoxide: silicon aerosol=1: 3~ 4: 0.6~1: 1.5~2: 0.02~0.3 The ratio of parts by weight weighs phosphoric acid, water, di-n-butylamine, aluminum isopropoxide and silicon aerosol, first adds phosphoric acid into water, stirs for 3min~10min, Obtain a phosphoric acid solution; 2. Under stirring conditions, add di-n-butylamine to the phosphoric acid solution obtained in step 1, and stir for 10 minutes to 20 minutes to obtain a mixed solution; 3. Under stirring conditions, add silicon aerosol and isopropyl Add the aluminum alkoxide to the mixed solution obtained in step 2, stir for 50min to 150min to obtain a gel; 4, put the gel obtained in step 3 in a reaction kettle, and heat it with a microwave with a power of 500W to 700W, at 130 to Cryst...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, by phosphoric acid: water: di-n-butylamine: aluminum isopropoxide: silicon aerosol=1: 3.2~3.8: 0.7~0.9: 1.6 Phosphoric acid, water, di-n-butylamine, aluminum isopropoxide and silicon aerosol are weighed in a ratio of parts by weight of ˜1.9:0.05˜0.28. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: this embodiment is different from specific embodiment one or two: in step one, by phosphoric acid: water: di-n-butylamine: aluminum isopropoxide: silicon aerosol=1: 3.5: 0.8: 1.8: 0.15 The ratio of parts by weight of phosphoric acid, water, di-n-butylamine, aluminum isopropoxide and silicon aerosol was weighed. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com