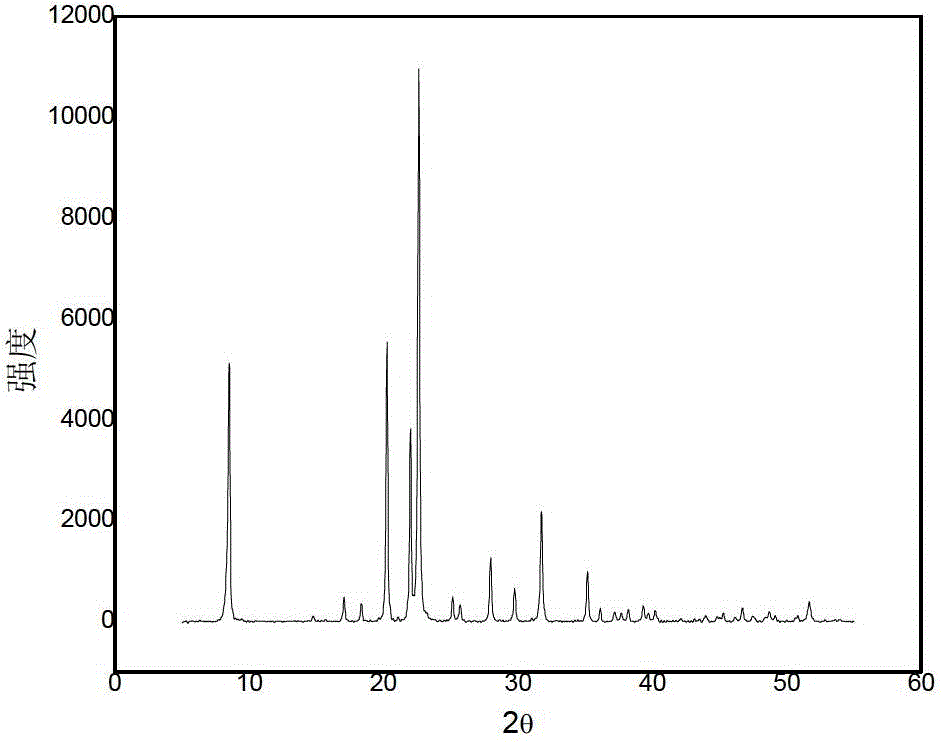

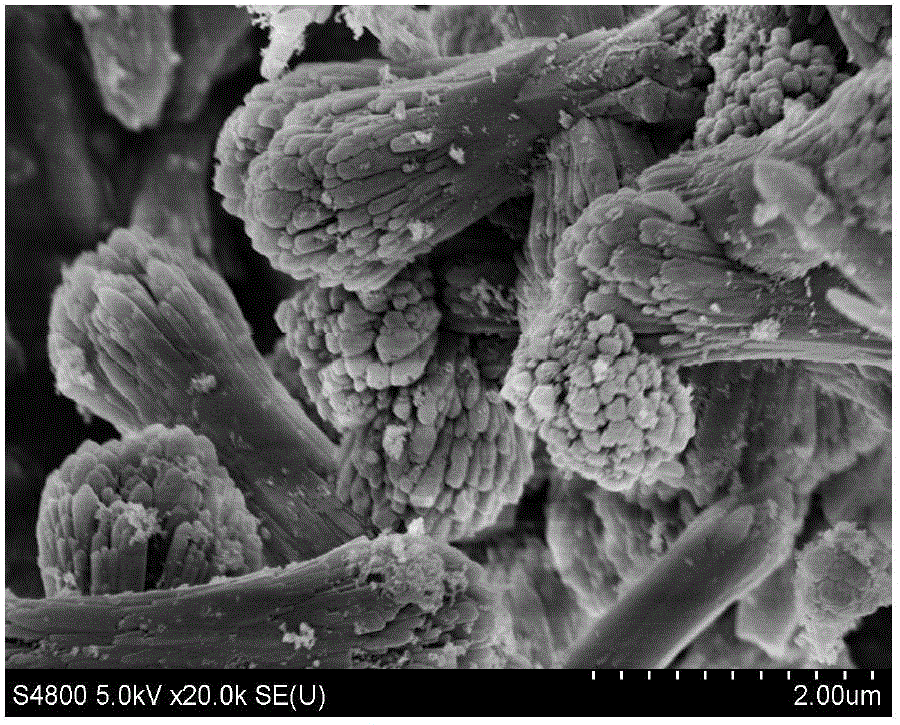

A method for synthesizing sapo-31 molecular sieve nanocrystals with double templates

A technology of SAPO-31 and double templating agent, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, nanotechnology, etc., can solve the problem of miscellaneous crystals, long crystallization time and large grain size in products etc. to achieve the effects of fewer structural defects, shorter crystallization time, and higher density of acidic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a method for synthesizing nanometer SAPO-31 molecular sieves with double templates, specifically as follows:

[0032] 1. Preparation of the initial gel: the mass fraction is 85% phosphoric acid solution, the mass fraction is 24.8% aluminum isopropoxide, silica aerosol, the mass fraction is 98.3% di-n-butylamine and the mass fraction is 95% The mixed solution of di-n-propylamine and the HF solution with a mass fraction of 40% were sequentially added to deionized water, fully stirred at 400-1000r / min for 0.5-3h, and the initial gel was obtained; 2. Crystallization: the The prepared initial gel was placed in a crystallization kettle, crystallized at 130-200°C for 3-36 hours, then cooled to room temperature, and the crystallized product was centrifugally filtered and washed, then put into a drying oven, and cooled at 100°C- Dry at 200°C for 8-36 hours, place the dried crystallized product in a muffle furnace, and roast at 500-650°C for 2-12 h...

Embodiment 2

[0037] The difference between this embodiment and Example 1 is that the mass ratio of the phosphoric acid solution with a mass fraction of 85% and the aluminum isopropoxide with a mass fraction of 24.8% added in step one is 1:(1.6~1.9); The mass fraction of adding is 85% phosphoric acid solution and the mass ratio of silicon dioxide aerosol is 1:(0.05 ~ 0.28); the mass fraction of adding is 85% phosphoric acid solution and mass fraction is 98.3% The mass ratio of butylamine is 1:(0.3~0.9); The mass fraction of adding is that the mass fraction of 85% phosphoric acid solution and mass fraction is 1:(0.3~0.9) of the di-n-propylamine mass ratio of 95%; The added mass fraction is 85% phosphoric acid solution and the mass ratio of 40% HF solution is 1:(0.01 ~ 0.05); the added mass fraction is the mass ratio of 85% phosphoric acid solution and deionized water It is 1: (3.2~4). Others are the same as in Example 1.

Embodiment 3

[0039] One of the differences between this embodiment and Embodiments 1 to 2 is that the mass ratio of the phosphoric acid solution with a mass fraction of 85% and the aluminum isopropoxide with a mass fraction of 24.8% added in step 1 is 1:1.8; The mass fraction of the phosphoric acid solution added is 85% and the mass ratio of silicon dioxide aerosol is 1:0.15; the mass fraction of the added phosphoric acid solution and the mass fraction of 98.3% is the mass The ratio is 1:0.4; the mass fraction of the added phosphoric acid solution and the mass fraction of 95% is 1:0.4; the added mass fraction is the phosphoric acid solution of 85% and the mass fraction The mass ratio of the HF solution with a fraction of 40% is 1:0.02; the mass ratio of the added phosphoric acid solution with a mass fraction of 85% to deionized water is 1:3.5. Other is identical with embodiment 1~2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com