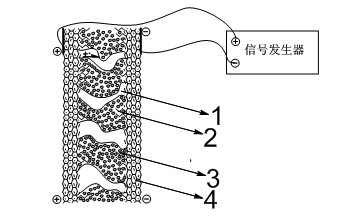

Graphene-ion exchange polymer electric actuator as well as manufacturing method and application thereof

An ion exchange, electric actuator technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of small force output and actuation of artificial muscle materials. The performance output is unstable and the cost is high. It achieves the effect of good compatibility, improved electric actuation performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1.Hummers synthesizes graphene monomolecular film

[0056] Add 250mL of 98% concentrated sulfuric acid to a 2L flask and cool it to 0°C with the cooling liquid in the low-temperature cooling circulating liquid pump, add 10g of natural flake graphite, 5g of NaNO 3 and 30g KMnO4 powder, control the temperature of the reaction solution at 10-15°C, and stir for more than 12 hours. The reaction at this stage is called a low-temperature reaction. Remove the low-temperature cooling circulating liquid pump, place the beaker in a warm water bath pre-heated to about 35°C, and continue stirring for 30 minutes when the temperature of the reaction solution rises to about 35°C, and the medium-temperature reaction is completed. Finally, carry out high-temperature reaction, that is, add 460mL deionized water during stirring, and when the temperature of the reaction solution rises to about 100°C, continue to stir and react for 30 minutes, remove the stirrer and warm water bat...

Embodiment 2

[0059] Embodiment 2. Vapor deposition (CVD) graphene monomolecular film

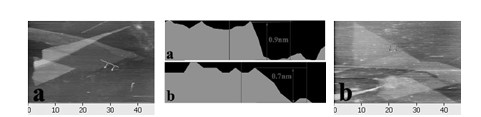

[0060] Use 25 micron thick copper foil as the substrate, maintain the growth temperature at 950-1000°C, feed methane and hydrogen, the gas flow rate is 25 sccm methane, 10 sccm hydrogen, after 15 minutes of growth, turn off the methane, and quickly cool down to room temperature under the protection of 10 sccm hydrogen gas flow , to obtain a copper / graphene monomolecular film. The sample was placed in FeCl 3 Remove the copper foil from the solution (0.1Mol / L), take a little clear liquid and disperse it on the mica surface for AFM analysis. The results show that the thickness of the graphene monomolecular film is between 0.3-0.9nm. The graphene monomolecular film is analyzed by total reflection infrared. The result shows: 1600cm -1 The strong absorption peaks of graphene appear on the left and right.

Embodiment 3

[0061] Embodiment 3. The sulfonation of graphene monomolecular film

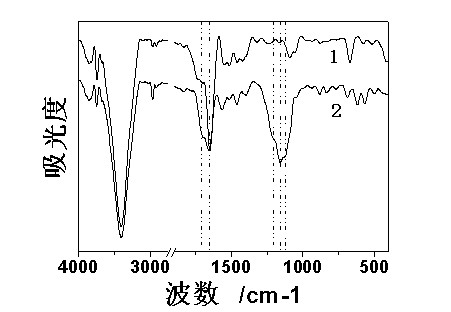

[0062] At 0°C, take 50 mg of graphene oxide monomolecular membrane aqueous solution, add 200 mg of azobenzenesulfonic acid, react for 2 hours, collect sulfonated graphene oxide precipitate, wash, dry, and do IR analysis ( figure 2 ). 1600cm -1 The left and right absorption peaks come from graphene itself; at 1060-1365cm -1 There are infrared absorption peaks of C-O, C-O-C, and O-H, at 1698cm -1 The absorption peak of C=O appeared at , indicating that graphene exists in an oxidized state; at 1208cm -1 and 1150cm -1 A strong sulfonic acid absorption peak appeared at , indicating that the benzenesulfonic acid groups had been coupled on graphene.

[0063] Put the copper / graphene monomolecular film grown by CVD into the azobenzenesulfonic acid solution and incubate for 2 hours, take out the substrate, and do total reflection infrared (ATR), the result: 1600cm -1The left and right absorption peaks come from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com