A Conveyor Belt Online Monitoring System and Method Based on Machine Vision

A machine vision and monitoring system technology, applied in conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems of lack of comprehensive detection of conveyor belt fault detection, achieve safe and reliable operation, achieve predictive maintenance, improve The effect of detection efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

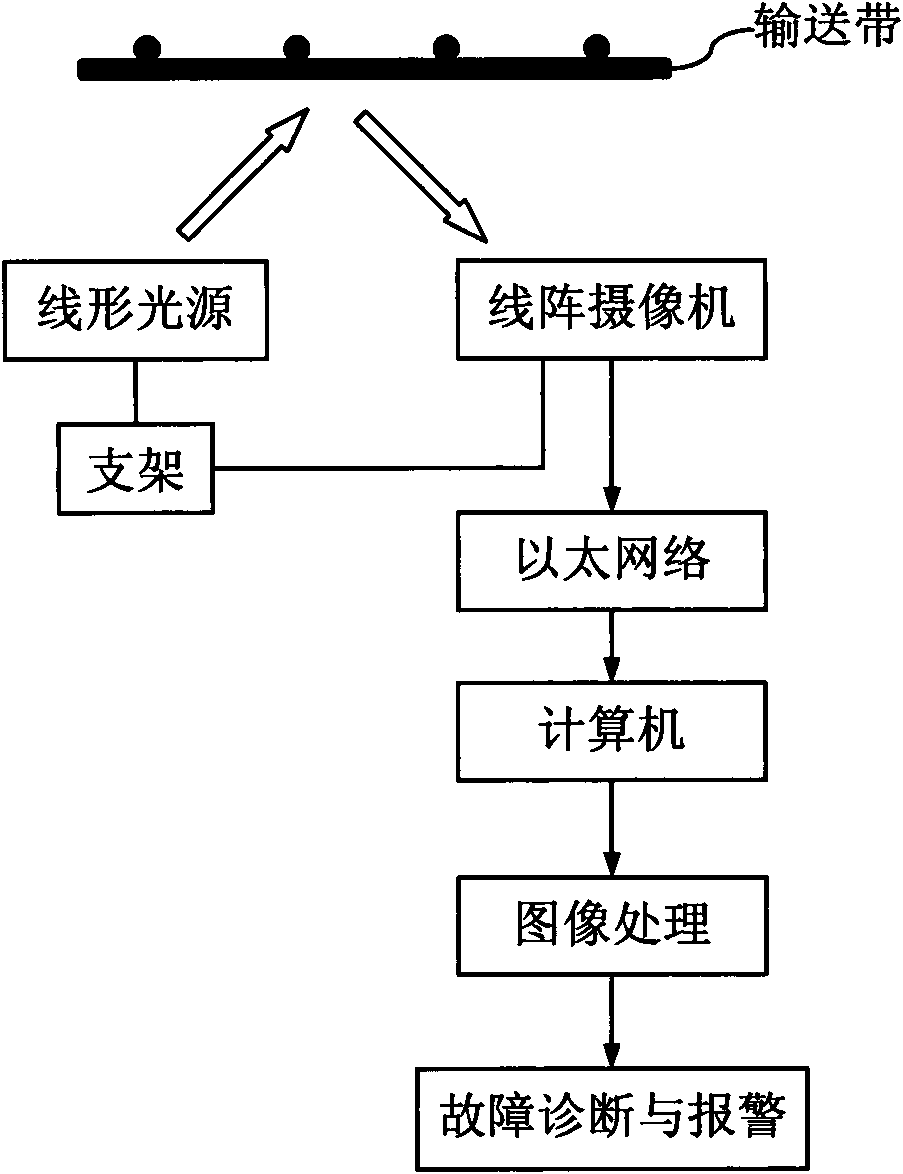

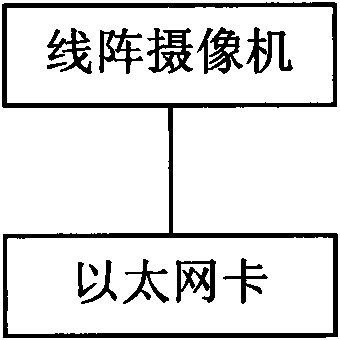

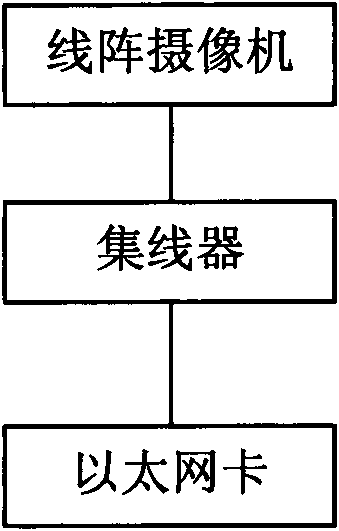

[0048] In this embodiment, an industrial-grade linear array CCD camera and a Gigabit Ethernet network are taken as examples for illustration. The schematic diagram of the conveyor belt online monitoring system is as follows: Figure 9 shown. The number of pixels of the industrial-grade linear array CCD camera can be selected according to actual needs.

[0049] The image information of the conveyor belt is collected in real time by an industrial-grade linear array CCD camera, and the image information of the conveyor belt is transmitted to the computer through the Gigabit Ethernet network, and the computer is used to process the running image of the conveyor belt, thereby realizing the monitoring and monitoring of the running state of the conveyor belt. Troubleshooting. For example: for an industrial-grade linear array CCD camera with 2048 pixels and a working line frequency of 19kHz, when monitoring a conveyor belt running at a speed of 6m / s, it will generate 37.1MB of image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com