Method for preparing mulberry leaf beverage by virtue of enzymatic transformation of flavonoids from mulberry leaves

A technology of mulberry leaf flavonoids and enzymatic conversion, applied in food preparation, application, food science, etc., to achieve the effect of high-tech content, sweet and sour taste, and large market development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

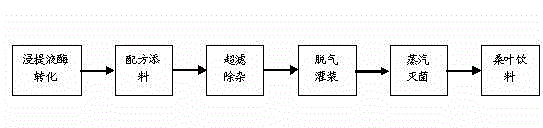

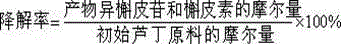

Method used

Image

Examples

Embodiment 1

[0032] The formula of this embodiment is: based on 100 kg of product, 10 kg of enzymatic hydrolyzate of mulberry leaf extract, 7 kg of sucrose, 0.10 kg of citric acid, 0.125 kg of vitamin C, 0.01 kg of black tea essence, 1.5 kg of honey, and the rest are pure water.

[0033] The preparation process of this example is as follows: take fresh mulberry leaves, add pure water at a volume ratio of 1:5 kg / L, and then extract at 100 °C for 1 h to obtain a mulberry leaf extract. The columnar reactor with immobilized glycosidase was used for enzymatic hydrolysis reaction. The reaction temperature was 20 °C and the reaction time was 72 h. After the reaction, the enzymatic hydrolysis solution of mulberry leaf extract was obtained. Add sucrose and citric acid according to the recipe, stir and dissolve, then add honey, black tea essence and vitamin C, and stir evenly. The ultrafiltration membrane removes impurities, and then degasses and fills. Then raise the temperature to 95°C ± 2°C, an...

Embodiment 2

[0036] The formula of this embodiment is: based on 100 kg of product, 15 kg of enzymolysis solution of mulberry leaf extract, 4 kg of sucrose, 0.50 kg of citric acid, 0.125 kg of vitamin C, 0.01 kg of black tea essence, 0.5 kg of honey, and the rest are pure water.

[0037]The preparation process of this example is as follows: take fresh mulberry leaves, add pure water at a volume ratio of 1:50 (kg / L), and then extract at 60°C for 12 hours to obtain a mulberry leaf extract, and use a pump to transport the mulberry leaf extract through filling A columnar reactor with immobilized glycosidase was used for enzymatic hydrolysis reaction. The reaction temperature was 70 °C and the reaction time was 10 h. After the reaction, the enzymatic hydrolysis solution of mulberry leaf extract was obtained. Add sucrose and citric acid according to the recipe, stir and dissolve, then add honey, black tea essence and vitamin C, and stir evenly. The ultrafiltration membrane removes impurities, an...

Embodiment 3

[0040] The formula of this embodiment is: based on 100 kg of product, 12 kg of enzymolysis solution of mulberry leaf extract, 5.5 kg of sucrose, 0.18 kg of citric acid, 0.01 kg of black tea essence, 1.5 kg of honey, 0.125 kg of vitamin C, and the rest are pure water.

[0041] The preparation process of this example is as follows: take fresh mulberry leaves, add pure water at a volume ratio of 1:30 (kg / L), and then extract at 80°C for 6 h to obtain a mulberry leaf extract, and use a pump to transport the mulberry leaf extract through The columnar reactor filled with immobilized glycosidase was used for enzymatic hydrolysis reaction, the reaction temperature was 40 °C, and the reaction time was 24 h. After the reaction, the enzymatic hydrolysis solution of mulberry leaf extract was obtained. Add sucrose and citric acid according to the recipe, stir and dissolve, then add honey, black tea essence and vitamin C, and stir evenly. The ultrafiltration membrane removes impurities, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com