Method and apparatus for manufacturing electronic assemblies, electronic assemblies manufactured by the method or in the apparatus

A technology of equipment and electronic components, which is applied in the manufacture of electronic assembly and equipment. The use of this or in the field of electronic assembly manufactured in this equipment can solve the problem of expensive construction of RFID semiconductor components, and achieve the effect of increasing production and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

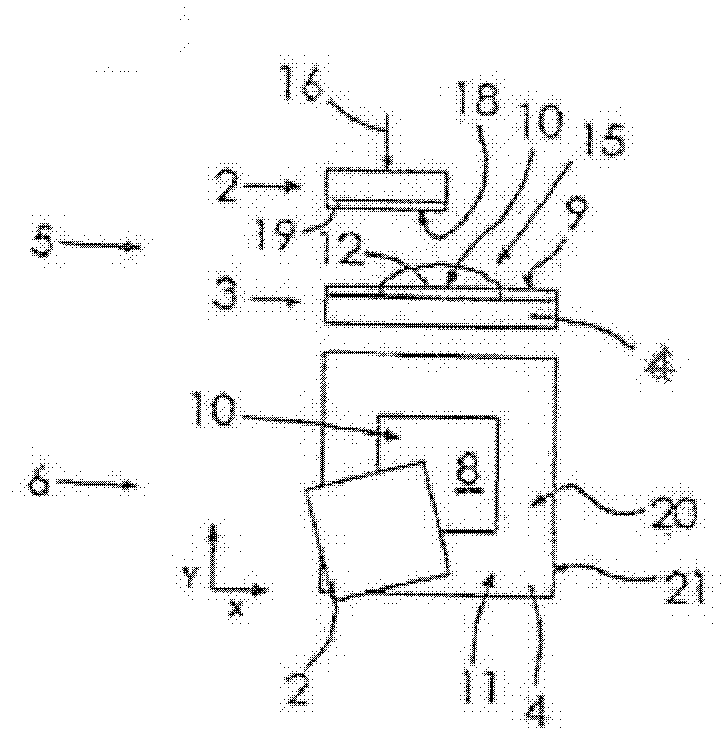

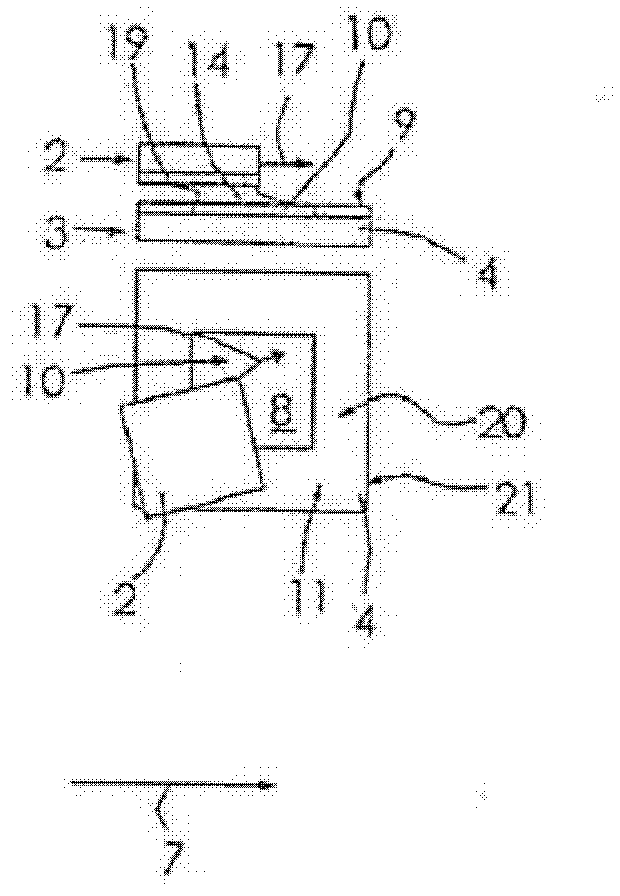

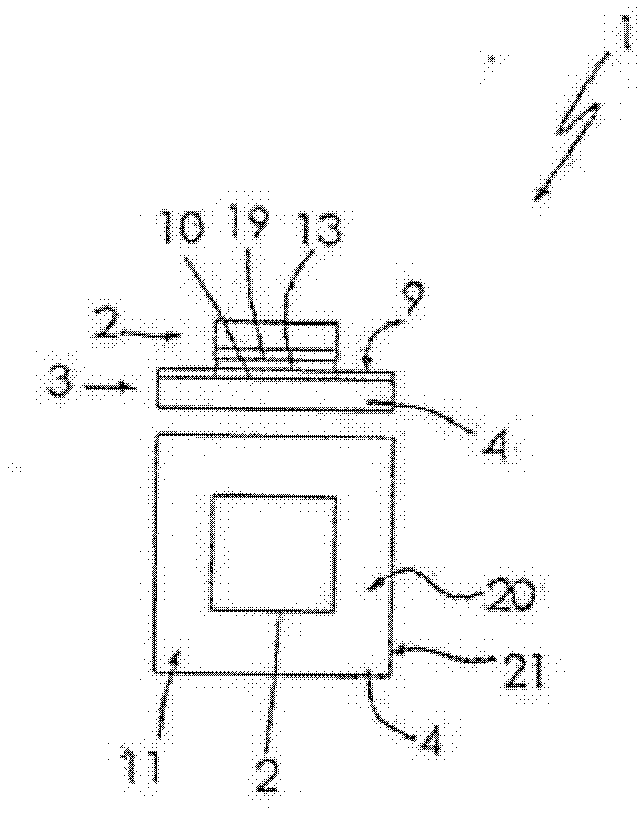

[0096] Shown in the figure is an example of a process chain of the above-mentioned method (variation method), in particular also for roller-to-roll processing of flexible substrates to flexible carriers (substrates) filled with small electronic components.

[0097] exist Figure 1 to Figure 3 In the method flow shown in, in order to produce semiconductor element 1 (see image 3 ), the chip 2 is placed contactlessly as an electronic component on a carrier substrate 3 , here in the form of a flexible film substrate 4 .

[0098] Will Figure 1 to Figure 3 split into upper side view Figure 5 and the plan view shown under this upper side view Image 6 , and proceed from left to right in the direction of arrow 7.

[0099] figure 1 It is a square fingerprint (footprint) area 8 formed on the film substrate 4 , and the area shape of the fingerprint area is adapted to the area shape of the chip 2 . Chip 2 is an electrical or electronic component part.

[0100] The surface 9 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com