Process technology and equipment for granulating blast-furnace slag and utilizing waste heat

A blast furnace slag and granulation technology, which is applied in the fields of ironmaking, blast furnace slag granulation and waste heat utilization technology and equipment, can solve the problems of slow cooling speed, lower use value, lower cement additive activity, etc., and reduce water quenching flow rate. , power reduction, the effect of saving new water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

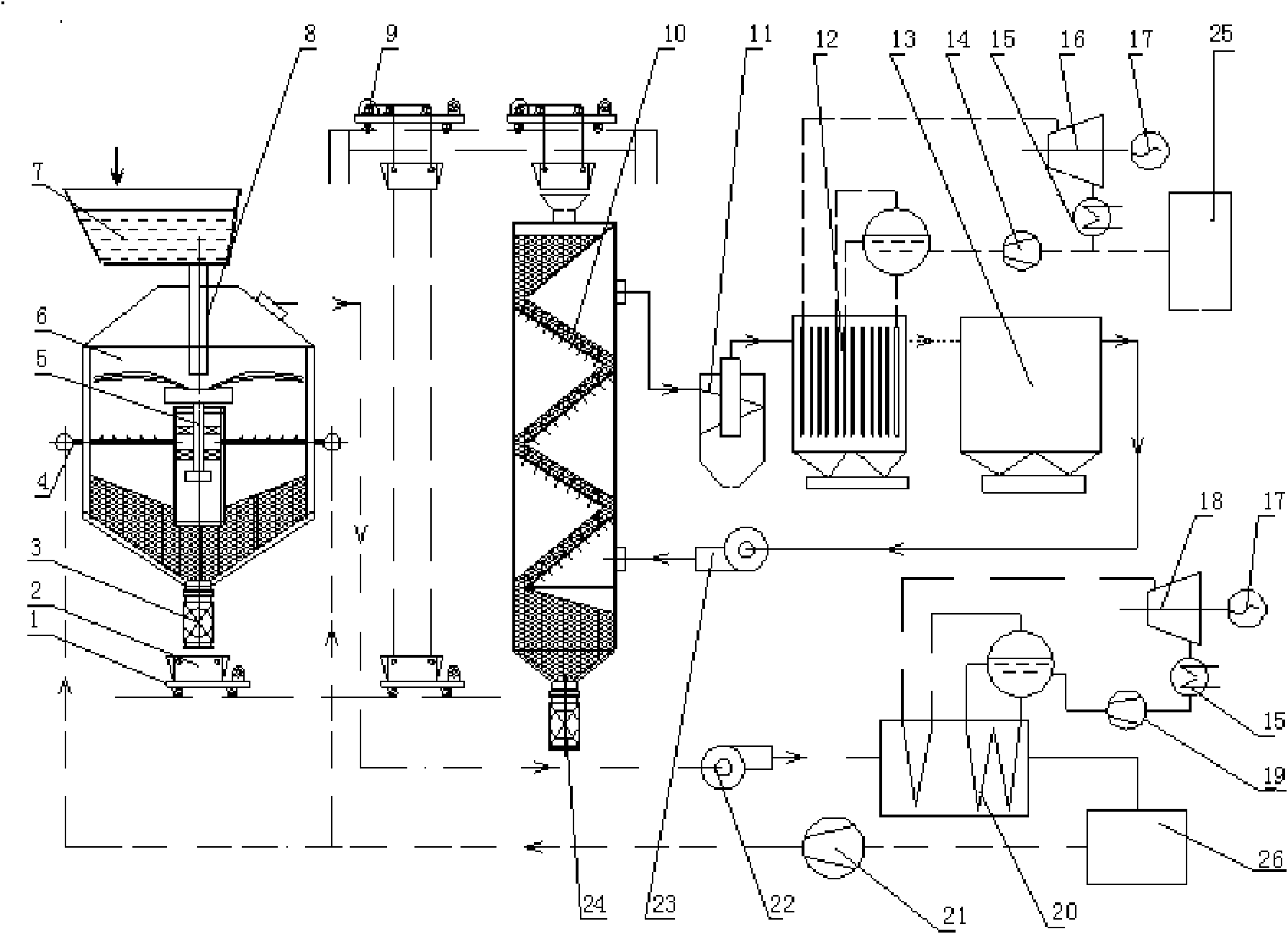

[0015] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

[0016] The specific implementation of the technical solution of the present invention includes the following two points at its core: one is that the high temperature section of the blast furnace slag above 800-1000 ° C requires high cooling speed, and adopts centrifugal granulation and water spray cooling to generate a normal pressure of 200 ° C Steam, and then use the organic media method that is especially suitable for waste heat recovery at around 200°C to recover the waste heat contained in the atmospheric pressure steam at 200°C to generate organic steam for power generation; the second is the low-temperature section of the blast furnace slag below 800-1000°C, using low-temperature Folded plate heat exchanger with flow resistance and circulating air cooling to generate hot circulating air above 600°C, and then use waste heat boiler method to reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com