Composite body of aluminum or aluminum alloy and plastic and manufacturing method thereof

A production method and technology of aluminum alloy, applied in metal material coating technology, electrolytic coating, polyester coating, etc., can solve problems such as limited application, aging and fracture of adhesive, and influence of operator proficiency, so as to broaden the scope of application and strengthen the binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

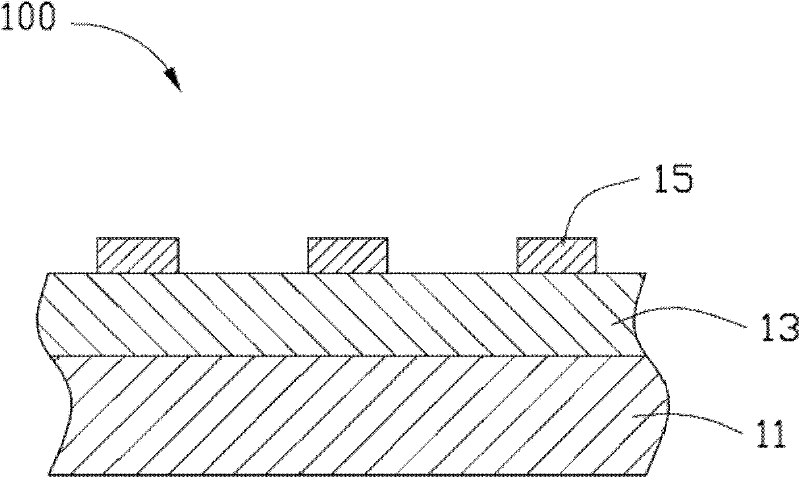

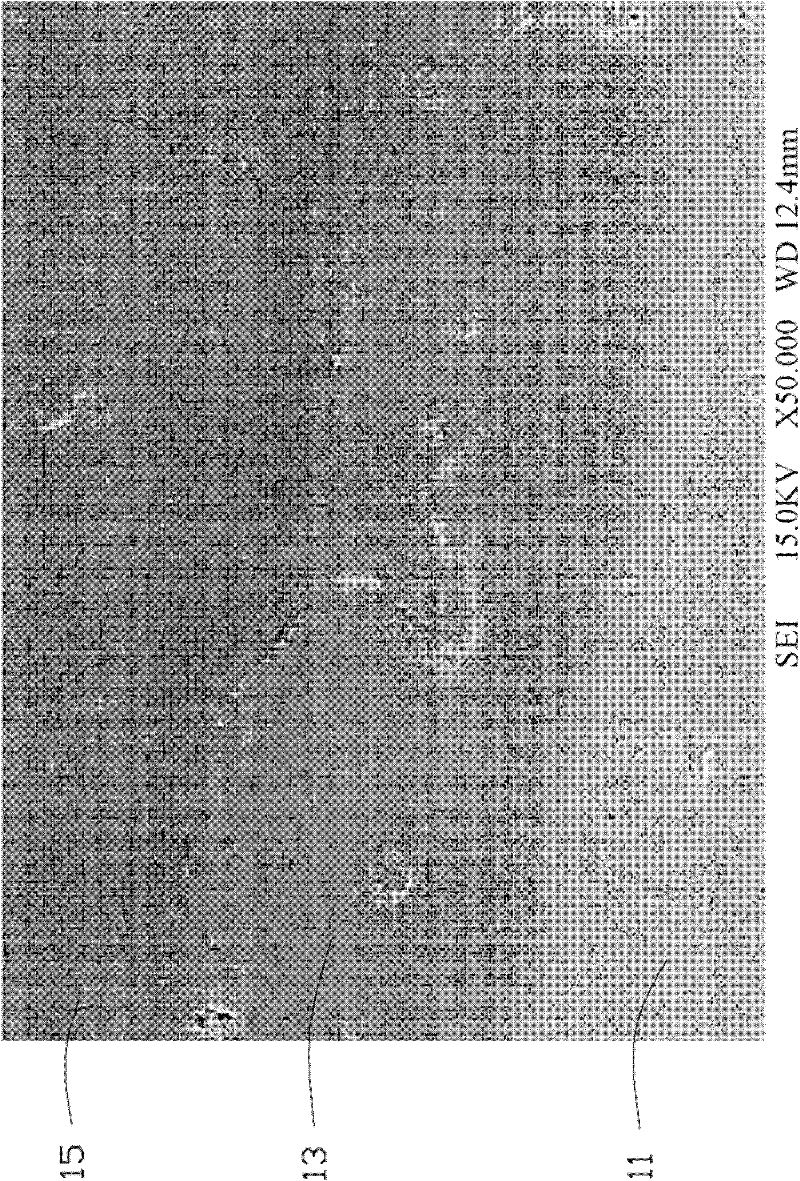

[0024] see figure 1 A composite 100 of aluminum or aluminum alloy and plastic in a preferred embodiment of the present invention includes an aluminum or aluminum alloy substrate 11, an anodized film 13 formed on the surface of the aluminum or aluminum alloy substrate 11, and the anodized film 13 Several plastic parts 15 combined.

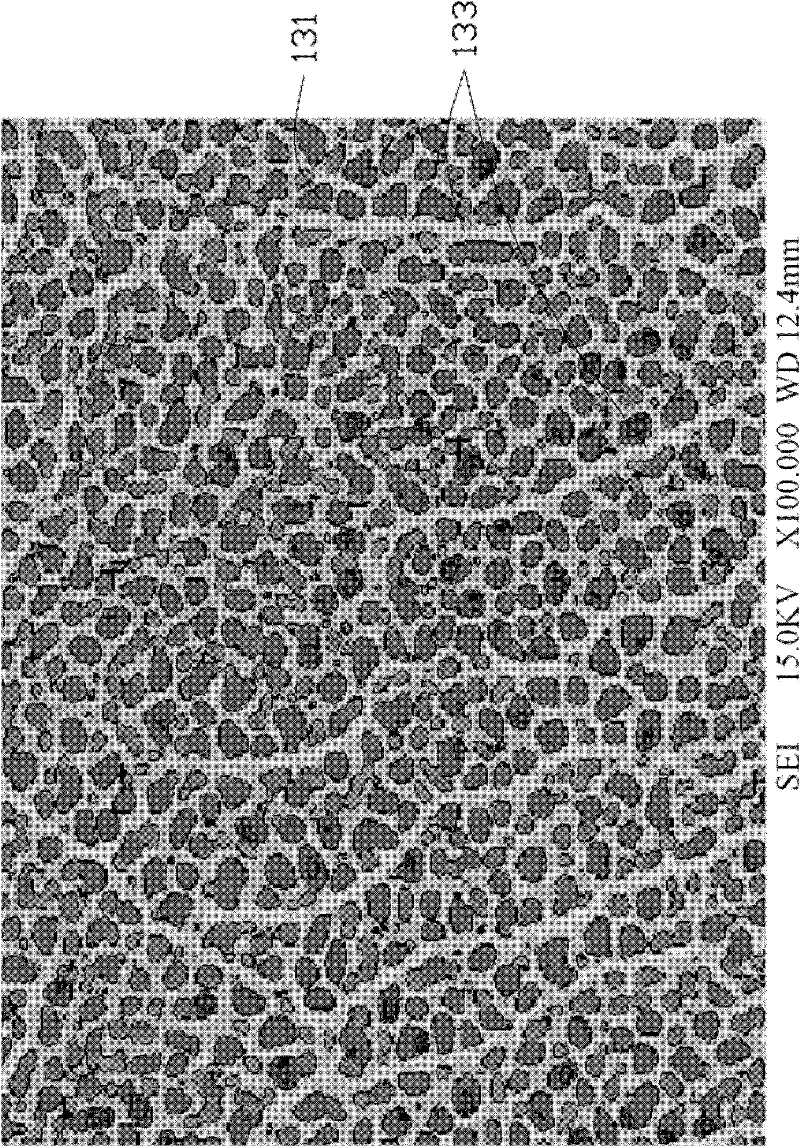

[0025] The anodized film 13 is an aluminum oxide film formed by anodizing the aluminum or aluminum alloy substrate 11 . see figure 2 As shown, the anodized film 13 is formed with several nanopores 131, and the average diameter of the several nanopores 131 is about 30-60 nm. The plurality of nanopores 131 can enhance the binding force between the plurality of plastic parts 15 and the anodized film 13 . From figure 2 It can be seen that the distribution of the plurality of nanopores 131 is relatively uniform, and some dendritic membrane ridges 133 are also formed in some areas on the surface of the anodized film 13, and the plurality of membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com