A large-volume electron-rich phosphine ligand catalyst and its preparation method and application

A catalyst and system technology, applied in the field of large-volume electron-rich phosphine ligand catalyst and its preparation, can solve the problems of not obtaining high-yield and high-molecular-weight polymers and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

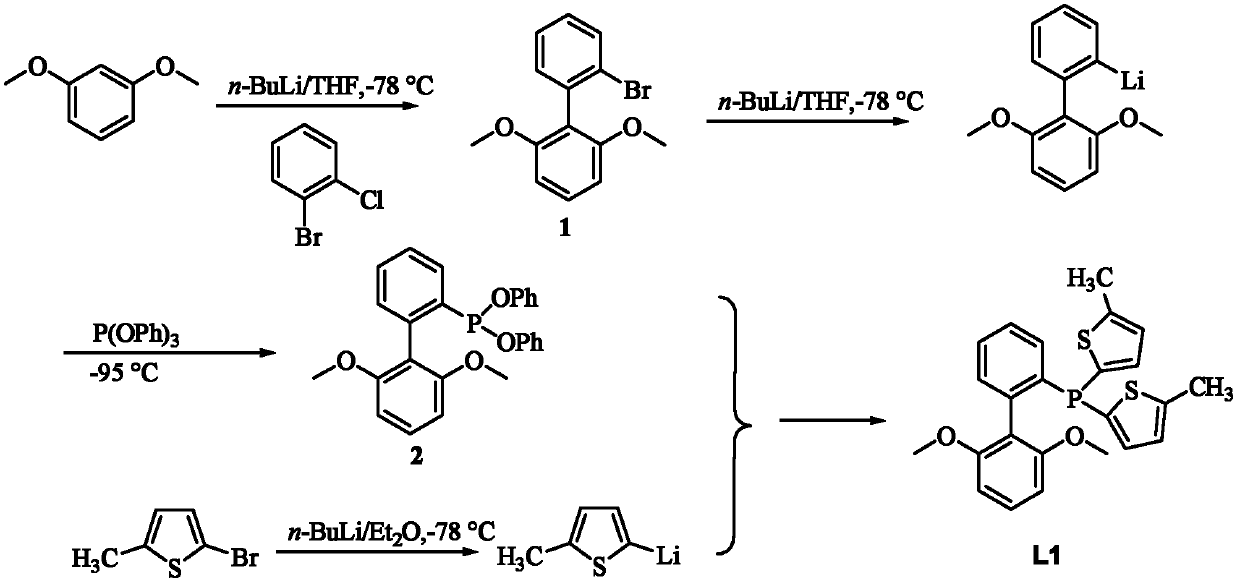

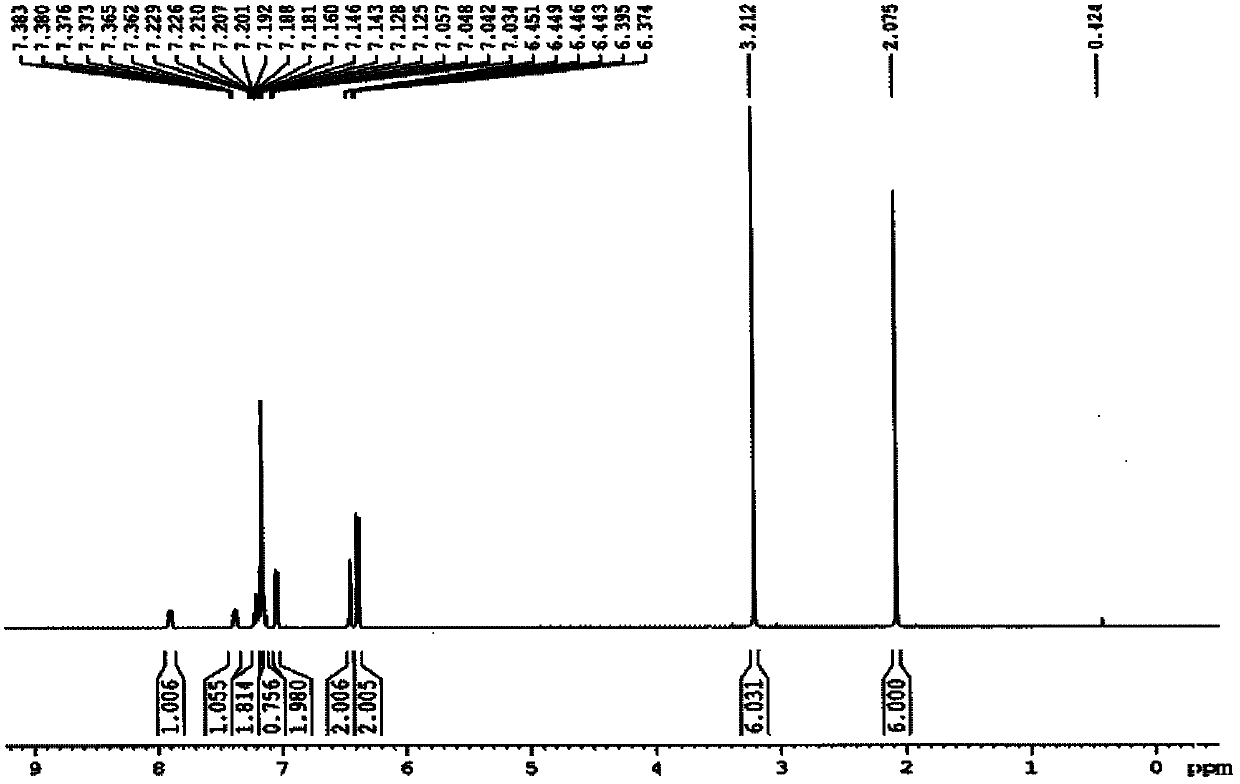

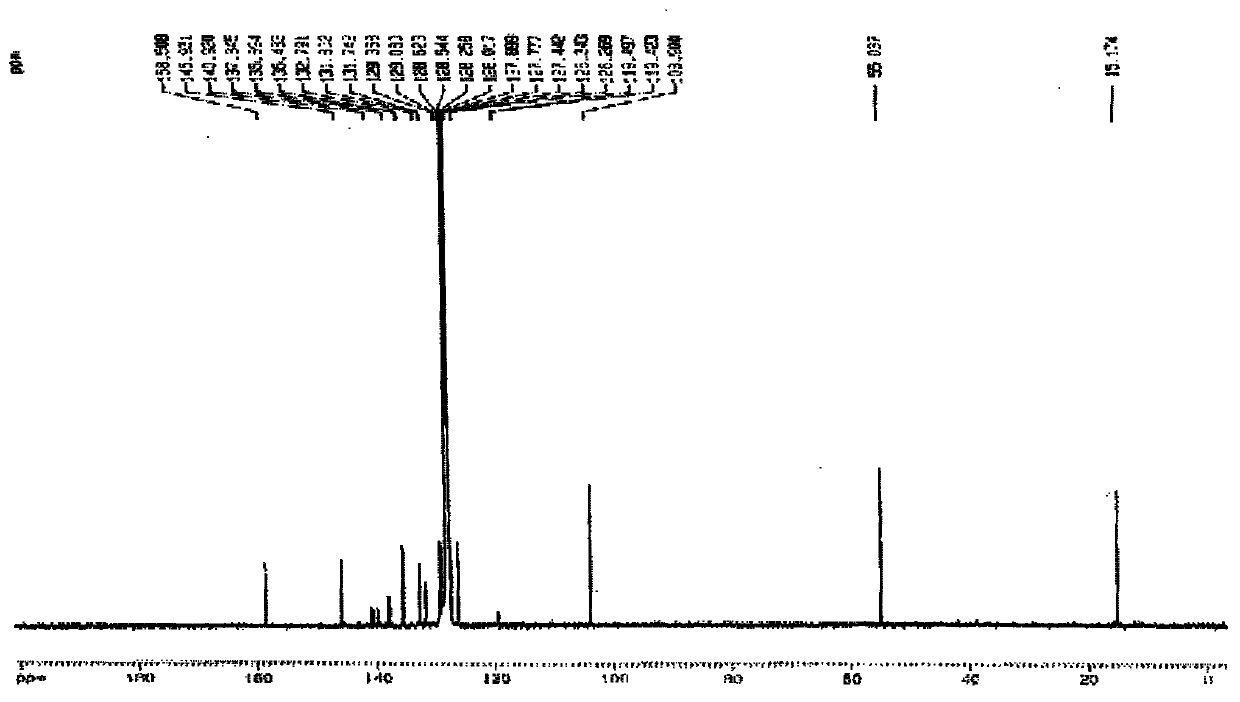

[0035] R in embodiment 1, preparation formula I is CH 3 Compound L1

[0036]

[0037] Compound 1 Compound 2 Compound L1

[0038] 1) Synthesis of compound 1: put 15mmol 1,3-dimethoxybenzene into the reaction flask, add 60ml of dry tetrahydrofuran (THF), and slowly drop into 15mmol n-BuLi (n-butyl base lithium) and then the reaction mixture was raised to room temperature to continue the reaction for 5-10 h, and then the reaction mixture was cooled to -78 ° C, and 14 mmol o-bromochlorobenzene was slowly added dropwise to obtain a light yellow crude product, which was recrystallized from methanol to obtain a white solid. Yield 84%.

[0039] 2) Synthesis of compound 2: Add 1 mmol of compound 1 to the reaction flask, add 100 ml of tetrahydrofuran, under nitrogen atmosphere, control the temperature at -78 ° C, slowly drop 1.2 mmol of n-BuLi, and continue stirring at this temperature for 20 min. The reaction mixture was cooled to -95°C, and 0.95 mmol P(OPh) was added by syringe ...

Embodiment 2

[0041] Embodiment 2, monomer G4 and M2 are in catalyst Pd2 (dba) 3 Polymerization under / L1 catalysis

[0042]

[0043] (Compound G4) (Compound M2)

[0044] PD 2 (dba) 3 Purchased from Shanghai Darui Fine Chemicals Co., Ltd., CAS code 51364-51-3 (52409-22-0).

[0045] Compound G4 was prepared with reference to the literature method, and the specific preparation method was as follows: (1) under nitrogen atmosphere, 1mol 1,4-dibromo-2-(bromomethyl)-5-toluene and 1mol phlorotriphenol were mixed, acetone was used as solvent, Then add 5mol of salt of wormwood, heat and reflux reaction, generate compound 5-(2,5-dibromo-4-methyl benzyloxy)-1,3-benzenediol;

[0046] (2) Under a nitrogen atmosphere, 1mol compound 5-(2,5-dibromo-4-methylbenzyloxy)-1,3-benzenediol is mixed with 2mol dimethyl (1,1-dimethylbenyloxy) Base) chlorosilane reacts to generate compound 3;

[0047] (3) Under nitrogen atmosphere, mix 1mol of 5-(bromomethyl)-1,3-benzenediol with 2mol of bromine, acetone as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com