A kind of nitrate sustained-release material and preparation method thereof

A slow-release material and nitrate technology, applied in chemical instruments and methods, biological sludge treatment, water/sludge/sewage treatment, etc., to achieve good slow-release effect, slow release process, and inhibit the release of sulfur and phosphorus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

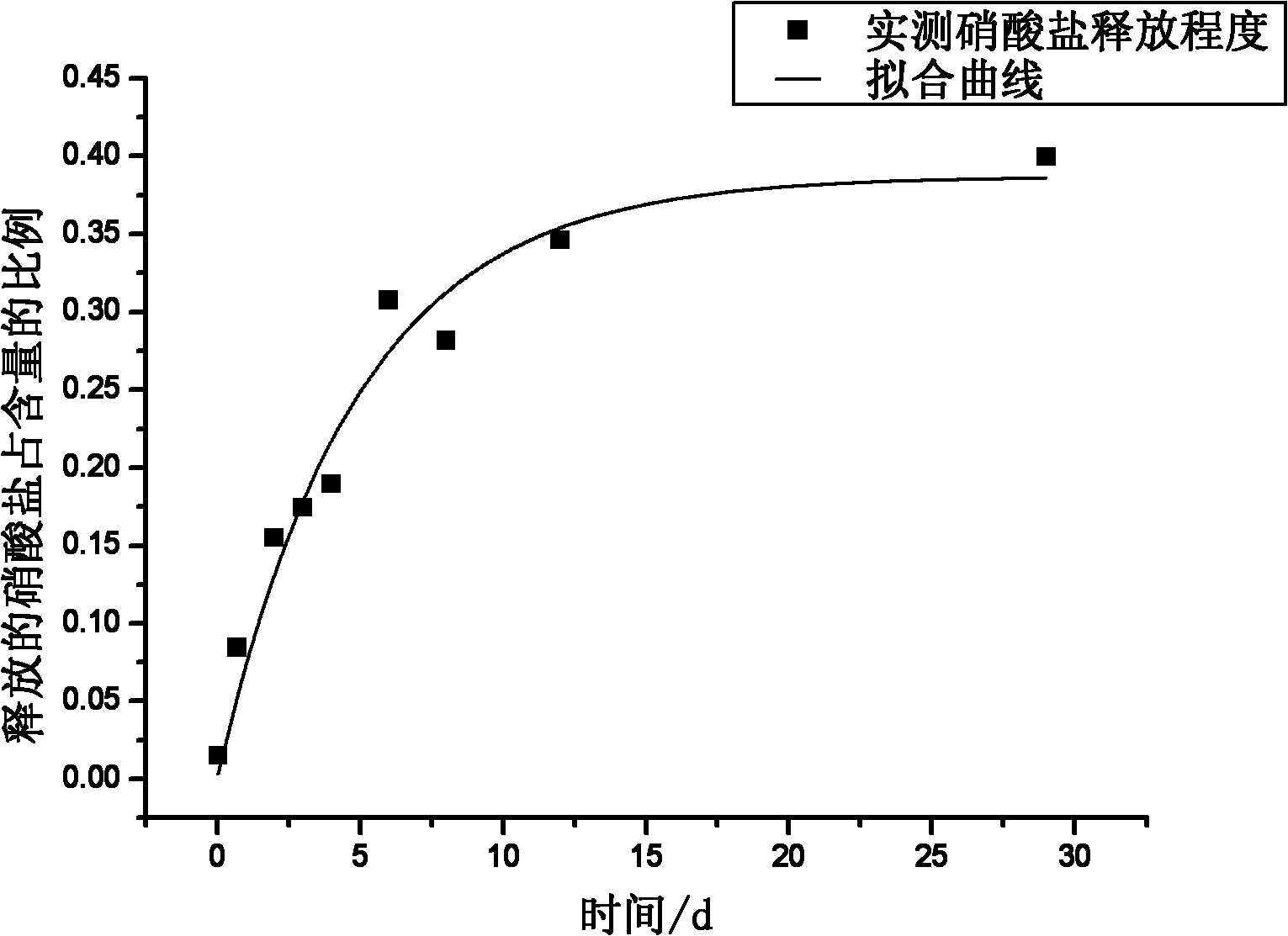

Embodiment 1

[0017] Dissolve 4.3kg of calcium nitrate in 33.2kg of pure water, mix it with 62.5kg of No. 425 ordinary Portland cement, put it in a cement standard curing box for curing for 7 days, and crush the cured material into pieces Small pieces with a thickness of about 10 mm are obtained as nitrate slow-release materials.

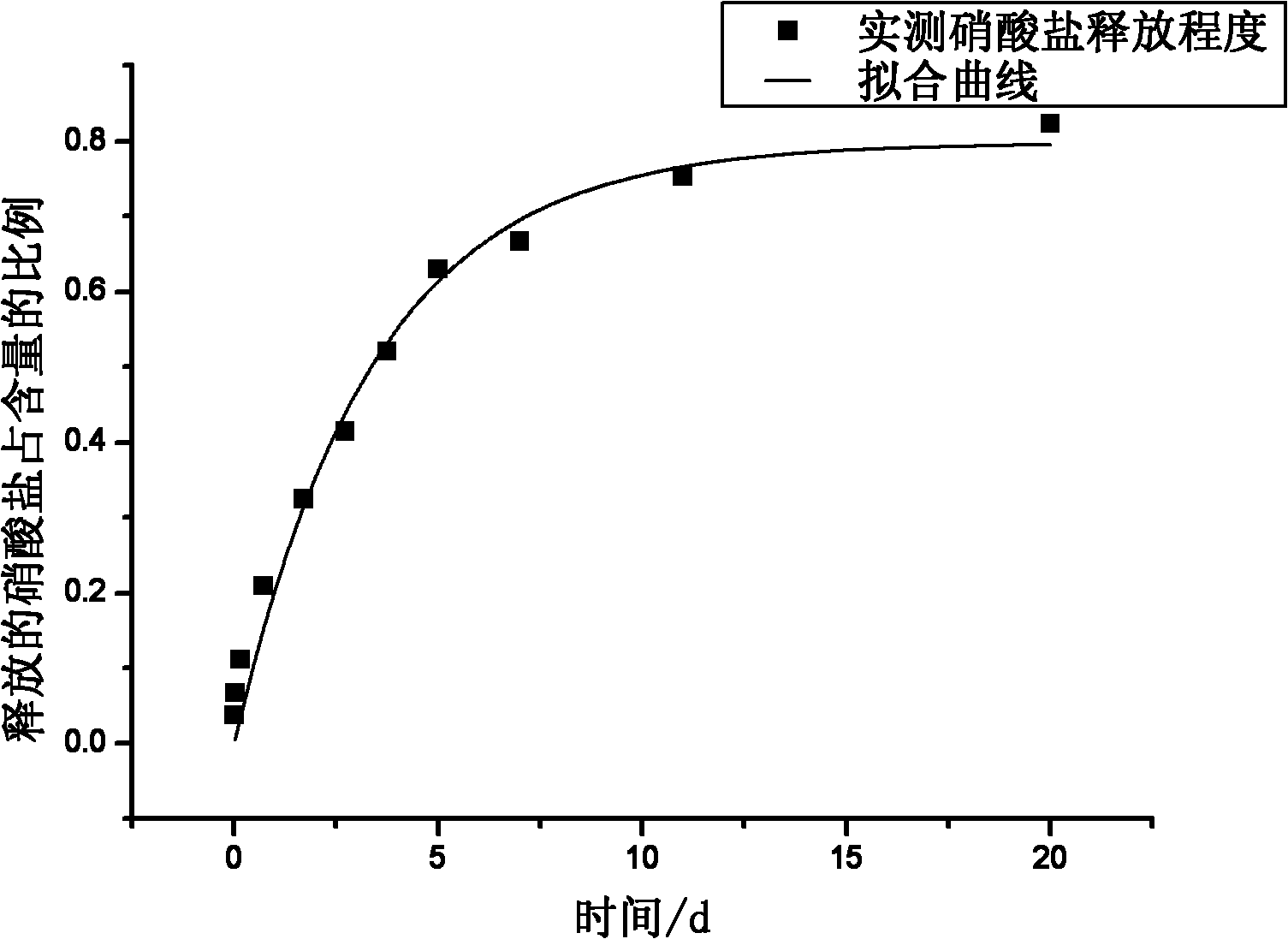

Embodiment 2

[0019] Dissolve 15.8kg of calcium nitrate in 29.6kg of pure water, mix 45.5kg of ordinary Portland cement with 9.1kg of kaolin to obtain a mixture, then mix the nitrate solution and the mixture evenly, and then put it in cement for standard curing Carry out curing in the box for 7 days and solidify, and crush the cured material into small pieces with a block size of about 6 mm to obtain the nitrate slow-release material.

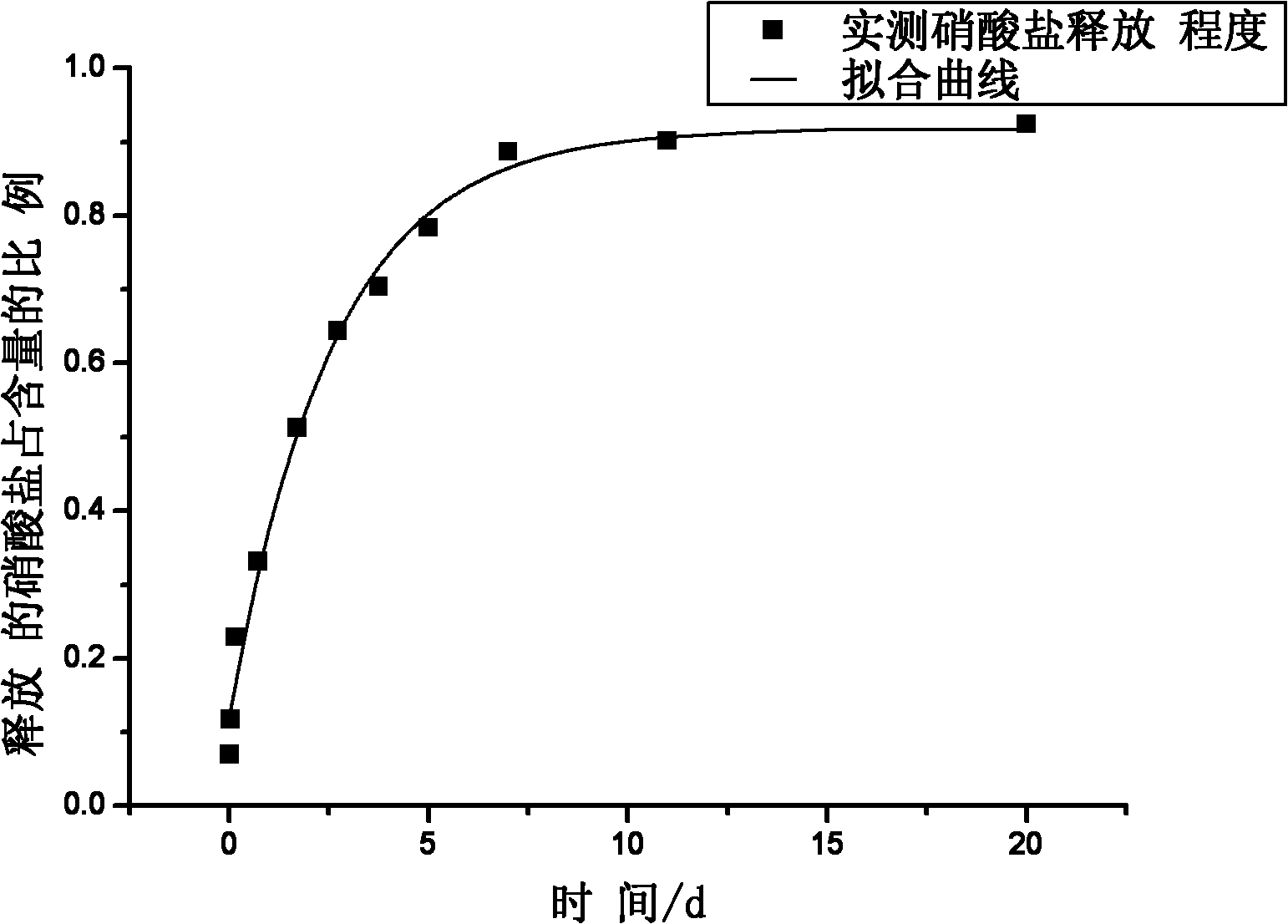

Embodiment 3

[0021] Dissolve 10.8kg of calcium nitrate in 23.7kg of pure water, mix 50.5kg of ordinary portland cement with 15kg of kaolin to obtain a mixture, then mix the nitrate solution and the mixture evenly, and then put it in the cement standard curing box Carry out curing in 7 days and solidify, and crush the cured material into small pieces with a block size of about 3 mm to obtain the nitrate slow-release material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com