Environment-friendly device for recycling and treating solvents in tail gas

An environmental protection device and tail gas technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem that the recovery speed and recovery rate of effective components cannot be balanced, and achieve ideal solvent recovery rate, waste prevention, and operation control Various and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

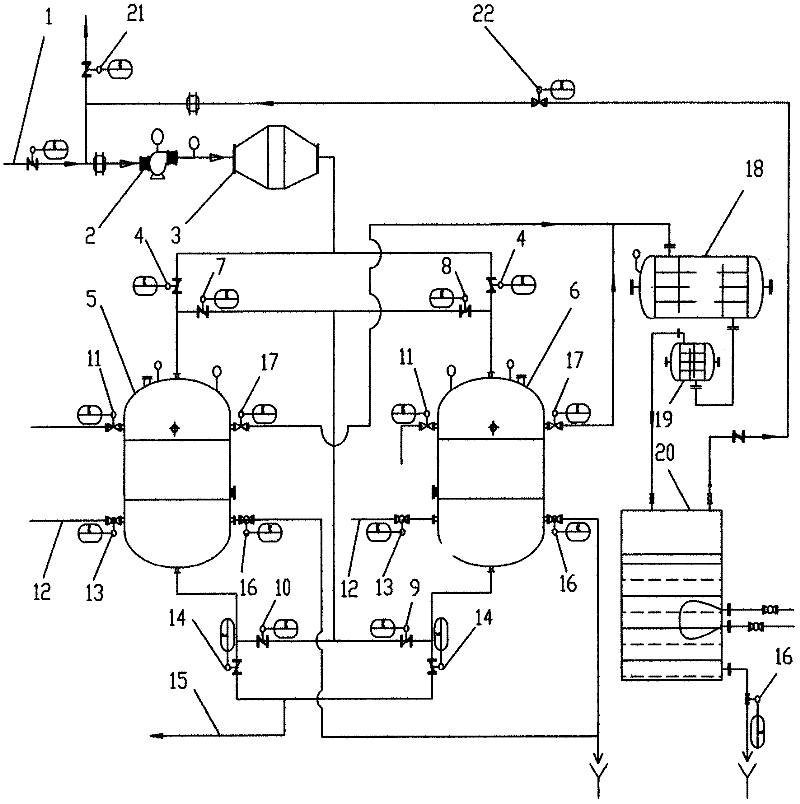

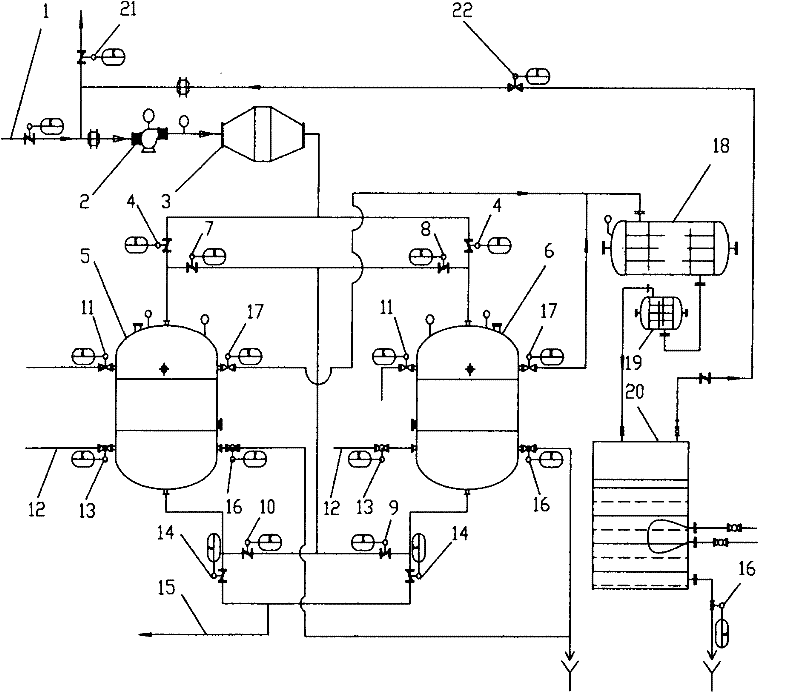

[0039] Parallel connection is adopted: valve 1 7, valve 2 8, valve 3 9, valve 4 10 are normally closed, and the rest of the valves need to be opened and closed according to the processing flow.

[0040] The tail gas is a mixture of solvent and air, and the solvent is hexane. The adsorption materials in the adsorption tower A5 and the adsorption tower B6 are activated carbon particles.

[0041] The valves mentioned above are all self-control type, connected to the self-control system, and the self-control system can control the switching action and switching time of each valve. The steam enters the steam pipeline from the steam inlet 12, and the steam pipeline is connected with a steam valve 13.

[0042] The tail gas enters from the upper end of the adsorption tower A5 or the adsorption tower B6, and the purified gas is discharged from the lower end of the adsorption tower A5 or the adsorption tower B6. The steam enters from the lower part of the adsorption tower A5 or the ad...

Embodiment 2

[0045] Adopt series connection form: valve 1 7, valve 4 10 normally open, valve 2 8, valve 3 9 normally closed; or, valve 2 8, valve 3 9 normally open, valve 1 7, valve 4 10 normally closed; other valves Normal switching is required by processing flow.

[0046] The tail gas is a mixture of solvent and air, and the solvent is a mixture of ordinary gasoline and 120# gasoline. The exhaust gas inlet 1 is connected with an exhaust pipeline and an exhaust valve 21 for use during device maintenance. An air cooler 3 is connected behind the fan 2 and in front of the adsorption tower A5. The adsorption materials in the adsorption tower A5 and the adsorption tower B6 are activated carbon fibers arranged in 3 layers.

[0047] Said valve is of self-control and manual double-acting type. During automatic control, the valve has a switch state feedback function, connected to the automatic control system, the automatic control system can control the switching action and switching time of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com