Loading fatigue tester

A technology of fatigue testing machine and loading mechanism, which is applied in the field of fatigue testing machine, can solve the problems of no corresponding method, low test efficiency, high cost, etc., and achieve the effects of long-term stable working performance, improved test efficiency, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

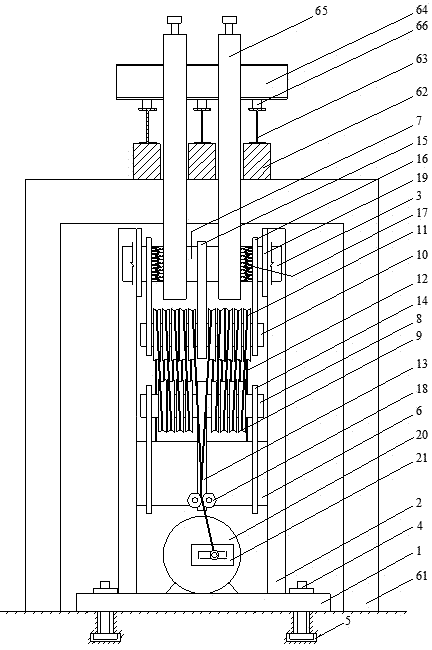

[0018] Embodiment one, as figure 1 Shown is a beam specimen loading testing machine, which is mainly composed of a main engine and a beam specimen reaction force device connected to the main engine. Wherein: the main engine is composed of three parts: an outer frame, a loading mechanism and a power mechanism; the outer frame is composed of a base 1 and a frame 3 arranged on the base 1 . The base 1 is fixedly connected to the trough 5 through the anchor bolt 4; the two frame columns 2 of the frame 3 are channel steel welded with a transverse partition at the top, and two vertical guide keys 19 are arranged on the inner side of the upper part of the two frame columns 2, and the top transverse partition Several connecting screw holes are provided, and the bottom end of the frame column 2 is fixed on the base 1 . The loading mechanism is arranged on the frame 3, and the power machine is arranged under the frame 3 and fixed on the base 1. The loading mechanism is mainly composed ...

Embodiment 2

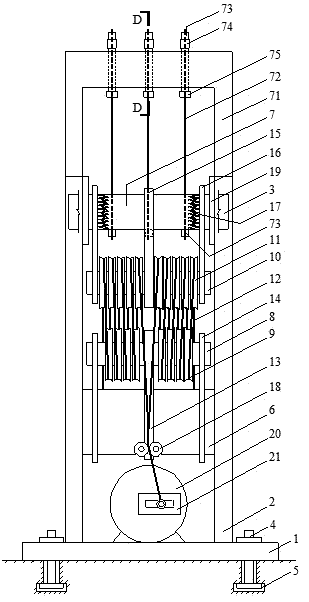

[0020] Embodiment two, such as figure 2 Shown is the steel bar test piece reaction force device testing machine 1. The test machine is mainly composed of a main engine and a steel bar test piece reaction force device connected to the main machine. Wherein the host computer is the same as the first embodiment, and the same parts are omitted. The steel bar test piece reaction force device comprises a steel bar test piece reaction force gantry 71 fixed on the main machine, the steel bar test piece reaction force gantry 71 is a single layer, and the steel bar test piece reaction force gantry 71 is provided with an upper beam A plurality of vertical hole positions on the 7 correspond to a plurality of steel bar holders with the same number of holes for fixing the steel bar test piece 72, and the steel bar holder is provided with a through-hole pressure sensor 74. Rebar anchors such as Figure 5 As shown, it includes a loading bolt 75 that is matched with the thread of the steel ...

Embodiment 3

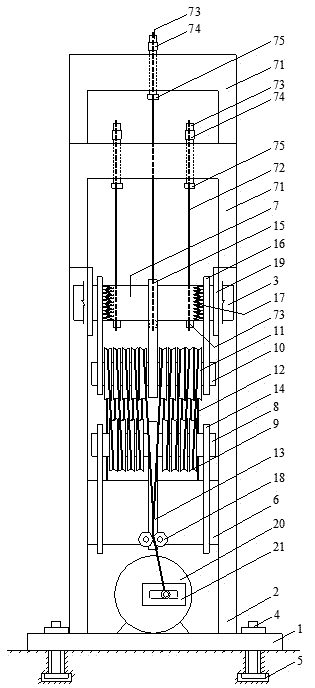

[0023] Embodiment three, as image 3 Shown is the steel bar test piece reaction force device testing machine II, which is basically the same as the second embodiment, and the same parts are omitted. The difference is that the structure of the steel bar test piece reaction gantry 71 is a double-layer structure, that is, the steel bar test piece reaction force device is divided into two layers, the steel bar test piece reaction force device in the middle is arranged on the top layer, and the steel bar test piece reaction force devices on both sides are arranged on the top layer. Symmetry is set on the lower floor. Since the vertical displacement of each specimen is the same, the difference in length must determine the difference in stiffness, which in turn must determine the difference in stress amplitude. Therefore, the multi-frame fatigue loading of the steel bar test piece can be realized by changing the length of the steel bar test piece, and by combining the steel bar test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com