Led device with light extracting rough structure and manufacturing methods thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to lighting devices, components of lighting devices, lighting and heating equipment, etc., can solve problems such as reducing light-emitting efficiency of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

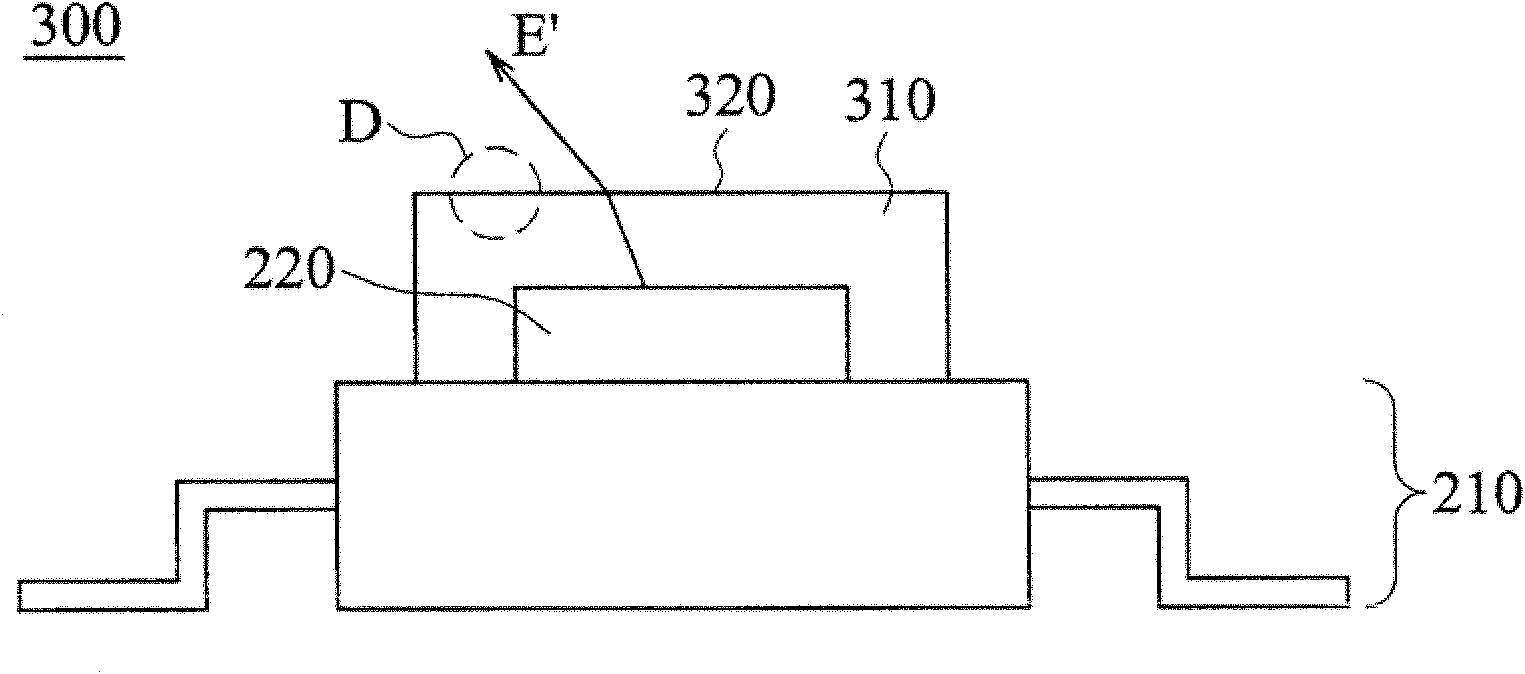

[0050] figure 2 A schematic diagram of a light emitting diode device 200 with a roughened light output structure according to an embodiment of the present invention is shown. Such as figure 2 As shown, the LED device 200 includes: a lead frame 210 ; an LED chip 220 electrically connected to the lead frame 210 ; a hemispherical packaging lens 230 for packaging the LED chip 220 and having a roughened surface 240 . image 3 A schematic diagram of a light emitting diode device 300 with a roughened light output structure according to another embodiment of the present invention is shown. Such as image 3 As shown, the construction of LED device 300 is similar to figure 2 The structure of the light-emitting diode device 200 shown is different in that: figure 2 The encapsulation lens 230 of the LED device 200 is hemispherical, and image 3 The packaging lens 310 of the LED device 300 is rectangular. Similarly, image 3 The packaging lens 310 also has a roughened surface 320...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com