High thermal efficiency steam generating device for caring products

A technology of steam generating device and nursing product, which is applied in steam generation, steam generation method, layered products, etc., can solve the problems of long heating time (more than 2 minutes, difficult to clean, large volume and space, etc., to achieve easy assembly and The effect of post-cleaning and maintenance, no leakage, safety and reliability, and high degree of modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

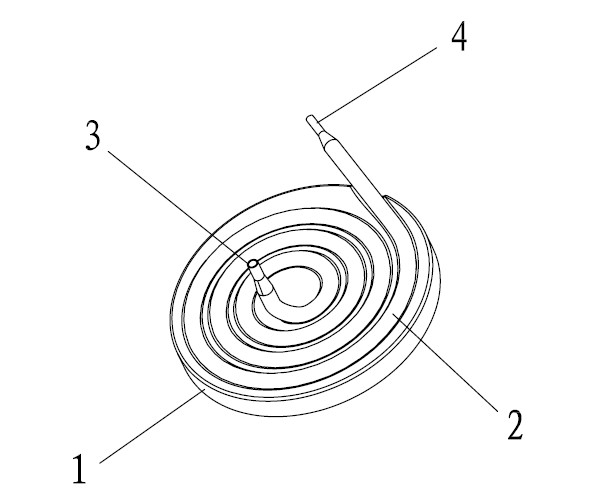

[0021] Such as Figures 1 to 5 As shown, the structure of the thick film heating element 1 involved in the patent of the present invention is divided into: a base 11 made of but not limited to stainless steel or ceramic materials; an insulating layer 12 made of insulating materials; Printed heating resistor layer 13; protective layer 14 made of materials with insulation and good thermal conductivity. The vaporization pipe 2 is closely attached to the base 11 and integrated with the heating element 1 . After the heating element 1 is energized, the heating resistor works to generate heat, which is transferred to the vaporization pipe 2 through the protective layer 14 .

[0022] Liquid water flows into the vaporization pipe 2 through the water inlet 3 of the vaporization pipe 2, absorbs the heat generated by the heating element 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com