Method for superhydrophobic finishing of textile

A textile and super water-repellent technology, applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve the problems of super water-repellent textile patents and literatures that have not been seen, and achieve the effect of soft hand feeling, high efficiency and safe environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

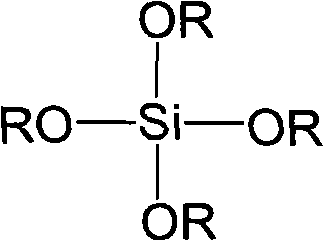

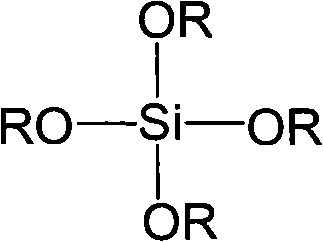

[0050] 0.5 g of 37% hydrochloric acid by mass was added into 500 g of deionized water, and stirred at room temperature for 10 minutes. Then 10 g of tetraethyl orthosilicate was added dropwise, stirring was continued for 60 minutes, and the solution was left to stand for 15 minutes to obtain a slightly bluish, transparent silica hydrosol. The Tyndall effect of the hydrosol was observed in the Tyndall phenomenon tester, and the average particle diameter of the hydrosol measured by Zetasizer Nano ZS nanometer particle size analyzer was 65.3nm. Cotton fabric (poplin, 40 s ×40 s / 133×72 (purchased from Hangzhou Tianrui Printing and Dyeing Co., Ltd.) was dipped twice and rolled twice in the prepared hydrosol, with a liquid retention rate of 80%, and dried at 120°C for 2 minutes.

[0051] 17.5g polydimethylsiloxane emulsion (TW-304, purchased from T-Win (SHANGHAI) Trading Ltd), 2.5g hydroxyl polydimethylsiloxane emulsion (YMR7212, purchased from MOMENTIVE Performance Materials), 2g...

Embodiment 2

[0056] Add 0.4 g of hydrochloric acid with a concentration of 37% by mass to 500 g of deionized water, and stir at room temperature for 10 minutes. Then 10 g of methyl orthosilicate was added dropwise, continued to stir for 60 minutes, and stood still for 15 minutes to obtain a slightly bluish, transparent silica hydrosol. The Tyndall effect of the hydrosol was observed in the Tyndall phenomenon tester, and the average particle diameter of the hydrosol measured by Zetasizer Nano ZS nanometer particle size analyzer was 72.1 nm. Cotton fabric (poplin, 40 s ×40 s / 133×72 (purchased from Hangzhou Tianrui Printing and Dyeing Co., Ltd.) was dipped twice and rolled twice in the prepared hydrosol, with a liquid retention rate of 80%, and dried at 120°C for 2 minutes.

[0057] Add 30g of polydimethylsiloxane emulsion (TW-304, purchased from T-Win (SHANGHAI) Trading Ltd) and 4g of titanium tetrachloride into 500g of deionized water, and stir evenly to prepare a finishing solution. Th...

Embodiment 3

[0062] 4 g of ammonia water with a concentration of 28% by mass was added to 500 g of deionized water, and stirred at room temperature for 10 minutes. Then, 12 g of tetraethyl orthosilicate was added dropwise, stirring was continued for 120 minutes, and the solution was allowed to stand for 30 minutes to obtain a slightly bluish, transparent silica hydrosol. The Tyndall effect of the hydrosol was observed in the Tyndall phenomenon tester, and the average particle diameter of the hydrosol measured by Zetasizer Nano ZS nanometer particle size analyzer was 98.4nm. Cotton fabric (poplin, 40 s ×40 s / 133×72 (purchased from Hangzhou Tianrui Printing and Dyeing Co., Ltd.) was dipped twice and rolled twice in the prepared hydrosol, with a liquid retention rate of 80%, and dried at 120°C for 2 minutes.

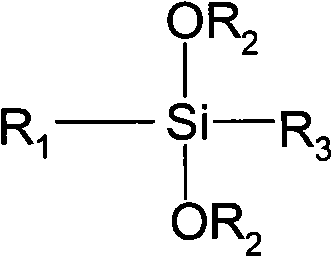

[0063] Add 12.5g of dodecyltriethoxysiloxane emulsion, 7.5g of hydroxyl polydimethylsiloxane emulsion (YMR7212, MOMENTIVE Performance Materials), 2g of titanium tetrachloride into 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com