Leaching method of low-grade copper oxide mud ore

A copper oxide, low-grade technology, applied in the field of hydrometallurgy, can solve the problems of difficult mining and utilization of copper oxide mud ore, unable to meet market demand, unable to obtain economic benefits, etc., to reduce labor intensity of workers, improve solid-liquid separation effect, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The main chemical components of the low-grade copper oxide slime processed in this embodiment are: 0.356% of free copper oxide, 0.436% of combined copper oxide, 0.072% of secondary copper sulfide, 0.429% of primary copper sulfide, Al 2 o 3 4.44%, SiO2 38.12%, Fe17.64%, CaO10.77%, MgO0.81%.

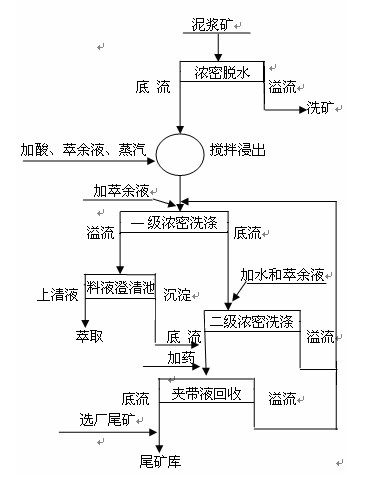

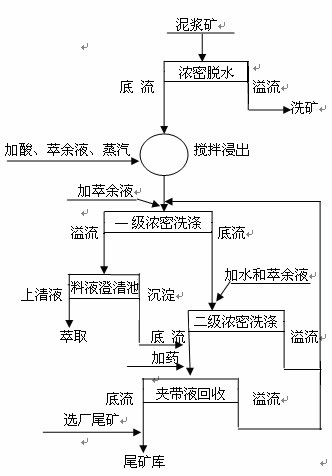

[0023] Through the following process steps:

[0024] A. Send the above-mentioned fine-grained ore slurry produced by the conventional ore washing process into the thickening tank, and perform concentration and dehydration according to the routine until the mass concentration of the underflow is 50%, and the overflow returns to the ore washing process for recycling, and the underflow automatically flows into the mixing tank;

[0025] B. In the mixing tank equipped with underflow in step A, add raffinate until the mass concentration of the underflow is 40%, then add sulfuric acid to the underflow according to the amount of 150g / l underflow, and feed waste heat steam from the sulfur...

Embodiment 2

[0030] The main chemical composition of the low-grade copper oxide slime processed in this embodiment is: 0.356% of free copper oxide, 0.435% of combined copper oxide, 0.071% of secondary copper sulfide, 0.43% of primary copper sulfide, Al 2 o 3 4.45%, SiO2 38.11%, Fe17.62%, CaO10.75%, MgO0.82%.

[0031] Through the following process steps:

[0032] A. Send the above-mentioned fine-grained ore slurry produced by the conventional ore washing process into the thickening tank, and perform concentration and dehydration according to the routine until the mass concentration of the underflow is 50%, and the overflow returns to the ore washing process for recycling, and the underflow automatically flows into the mixing tank;

[0033] B. In the mixing tank equipped with underflow in step A, add raffinate until the mass concentration of the underflow is 30%, and then add sulfuric acid to the underflow according to the amount of 100g / l underflow, and pass in waste heat steam from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com