Coal gasification method and device of suspension bed

A technology of coal gasification and suspended bed, which is applied in the direction of granular/powder fuel gasification, etc., can solve the problems that heat loss cannot be recovered, pollution cannot be completely eliminated, and the selection range of coal types is narrow, and the structure is simple and adaptable to coal types. Wide and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

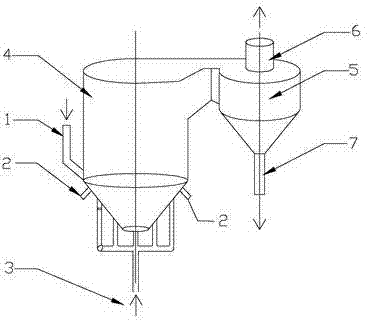

[0040] Such as figure 1 As shown, the present embodiment provides a suspended bed coal gasification device, including a gasifier 4 and a cyclone separator 5, the gasifier 4 includes a cylinder and a cone, and the cone is arranged at the lower part of the cylinder, A pulverized coal feed inlet 1 is provided on the side wall of the lower end of the cylinder of the gasification furnace 4, and 21 gasification agent nozzles 3 are uniformly arranged in two circles around the center of the cone at the bottom of the cone to form a conical air distribution surface. The side wall of the cone is provided with an ignition fire source 2, and the cylinder is connected with a cyclone separator 5. A slag outlet 7 is arranged at the lower end of the cyclone separator 5, and an air outlet 6 is arranged at the upper end.

[0041]During gasification, the igniter 2 at the lower part of the cone of the gasifier 4 is ignited first, and the temperature in the furnace is kept at 1000-1300°. The gasif...

Embodiment 2

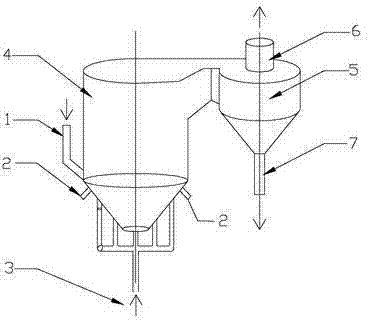

[0043] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the feeding positions of the gasification agent feed port and the pulverized coal feed port are changed, the side wall of the cone is provided with an ignition source 2, and the bottom is provided with 1 The pulverized coal feed port 1, the pulverized coal enters the gasifier from the bottom of the gasifier 4 at a certain speed and pressure; a plurality of gasification agent nozzles 3 are arranged on the side wall of the lower end of the cylinder, and the gasification agent flows along the gasification furnace. The lower part of 4 is fed tangentially, and a gas field capable of suspending pulverized coal is formed at the bottom of gasifier 4, so that pulverized coal can be burned and gasified in a stable suspended state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com