Method for producing alpha type high-strength gypsum powder by using desulfurization gypsum serving as industrial byproduct

A technology for desulfurizing gypsum and by-products, which is applied in the field of inorganic material preparation, can solve problems such as high cost and cumbersome process, and achieve the effects of simple ingredients, easy-to-obtain raw materials, and high social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

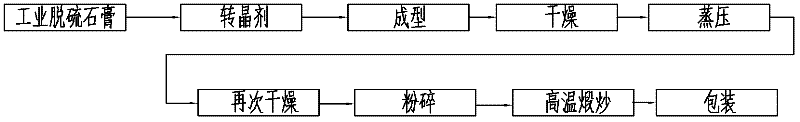

[0022] Such as figure 1 As shown, the α-type high-strength gypsum powder produced by industrial by-product desulfurization gypsum is obtained by the following method: take 100 parts of industrial by-product desulfurization gypsum, and extrude it into a certain geometric shape under a pressure of 0.5-5 MPa, and then Drying method: dry at a temperature lower than 80°C or dry naturally until the water content is ≤3%, and then dry at a pressure of 4-6kgf / cm 2 Autoclave for 4-6 hours and dry again until the water content is below 3%. Afterwards, it is crushed to pass through a 80-200 mesh sieve, and calcined at a high temperature of 120-210°C for 30-150 minutes to obtain α-type high-strength gypsum powder, which is packed and stored for later use.

Embodiment 2

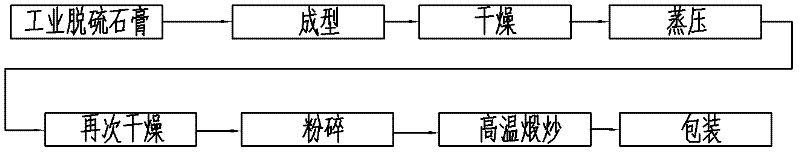

[0024] Such as figure 2 As shown, the α-type high-strength gypsum powder produced by the industrial by-product desulfurized gypsum is obtained by the following method: take 80 parts of the industrial by-product desulfurized gypsum, add β-type hemihydrate gypsum (CaSO 4 1 / 2H 2 O) 20 parts, stir evenly. And extrude it into a certain geometric shape under the pressure of 0.5 ~ 5MPa, then dry it at a temperature lower than 80°C or dry it naturally until the water content is ≤ 3%, and then dry it under a pressure of 4 ~ 6kgf / cm 2 Autoclave for 4-6 hours and dry again until the water content is less than 3%, then crush until it can pass through a 80-200 mesh sieve, and calcined at 120-210°C for 30-150 minutes to obtain α-type high-strength gypsum powder. Pack this α-type high-strength gypsum powder and put it aside for later use.

Embodiment 3

[0026] Such as figure 2 As shown, the α-type high-strength gypsum powder produced by the industrial by-product desulfurized gypsum is obtained by the following method: in parts by mass, take 95 parts of the industrial by-product desulfurized gypsum, add α-type hemihydrate gypsum (CaSO 4 1 / 2H 2 O) 5 parts, and extrude it into a certain geometric shape under a pressure of 0.5-5MPa, then dry it at a temperature lower than 80°C or naturally dry it to a water content of ≤3% in a conventional drying method, and then dry it under a pressure of 4 ~6kgf / cm 2 Autoclave for 4-6 hours and dry again until the water content is less than 3%, then crush until it can pass through a 80-200 mesh sieve, and calcined at 120-210°C for 30-150 minutes to obtain α-type high-strength gypsum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com