Method for biochemically treating and discharging refinery wastewater within controlling index of national standard

A technology for biochemical treatment and oil refinery sewage, applied in multi-stage water/sewage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve aggravated emulsification, low ability to remove ammonia nitrogen, and high-concentration sewage Impact increase and other issues, to save investment and operating costs, compact system structure, reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

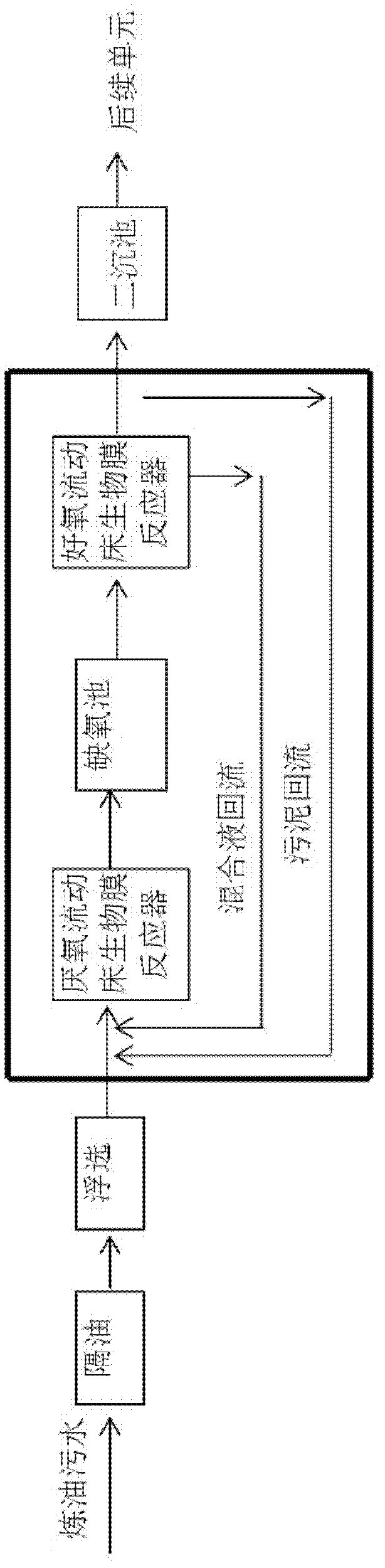

[0017] The invention relates to oil refinery sewage treatment technology, in particular to biochemical treatment technology for oil refinery sewage after flotation treatment. The combined process of "anaerobic fluidized bed biofilm reactor-anoxic-aerobic fluidized bed biofilm reactor" is mainly used to treat oil refinery sewage, and a safe and reliable biochemical treatment technology for oil refinery sewage is provided.

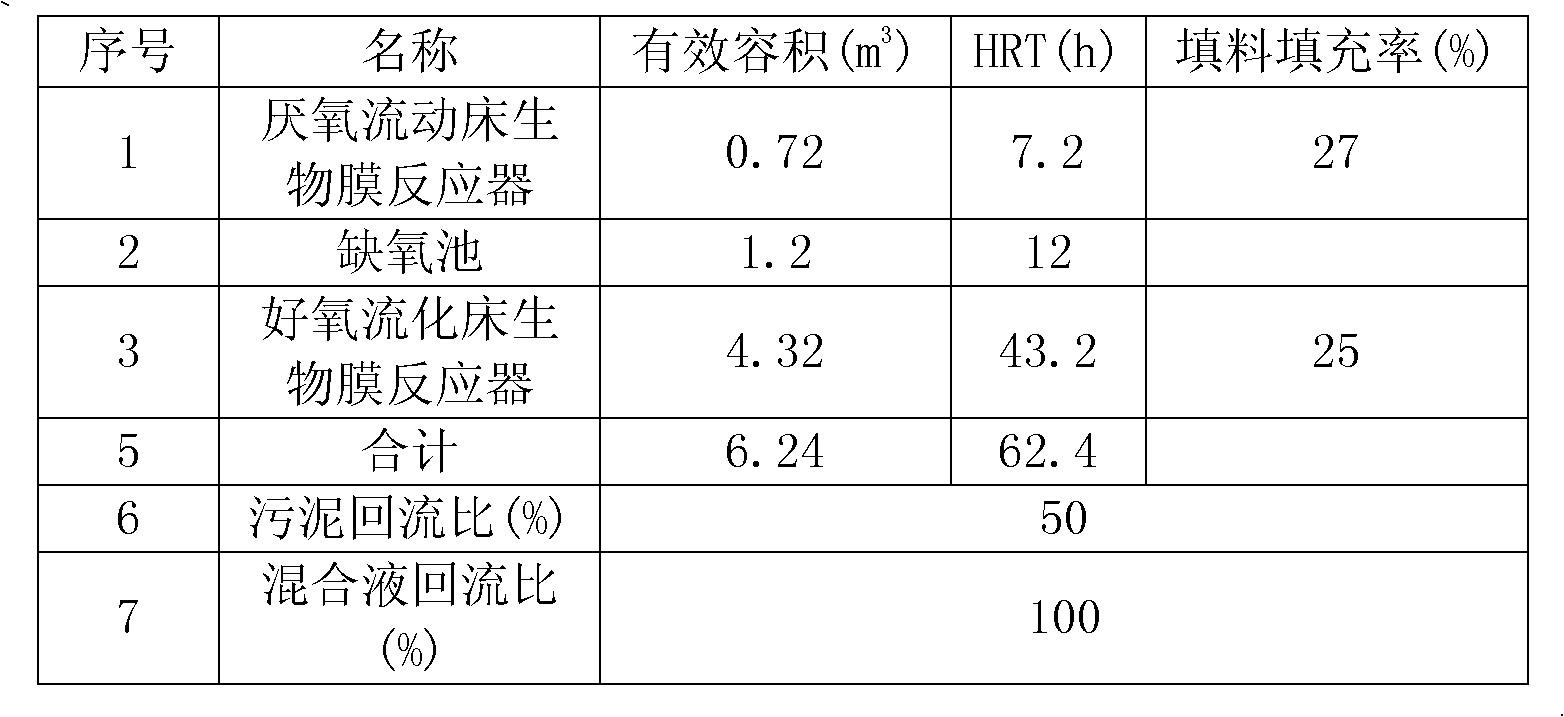

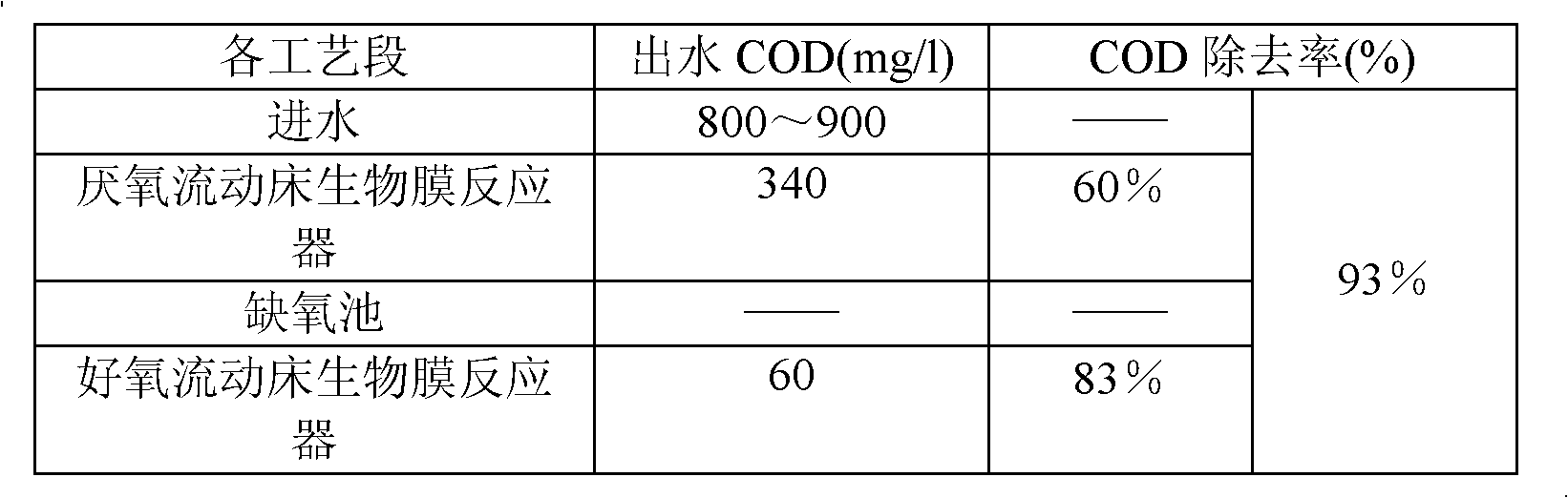

[0018] After flotation, the COD of the previous refinery sewage was around 400mg / l, and it reached 800mg / l under impact conditions. Due to the heavy and inferior quality of the current crude oil, after flotation, the COD is generally 800-1000mg / l, or even higher. The content of oil and salt in the sewage is relatively high, so the patent of the present invention adopts the biological treatment method of "anaerobic fluidized bed biofilm reactor-anoxic tank-aerobic fluidized bed biofilm reactor" resistant to high salt and high sulfur. A specific process such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com