Portable integrated machine for opening tube connecting and saddle-shaped weld joint welding

A saddle-shaped, all-in-one machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex process, low precision, high cost, etc., to increase system flexibility and prevent the pipe from tilting , The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

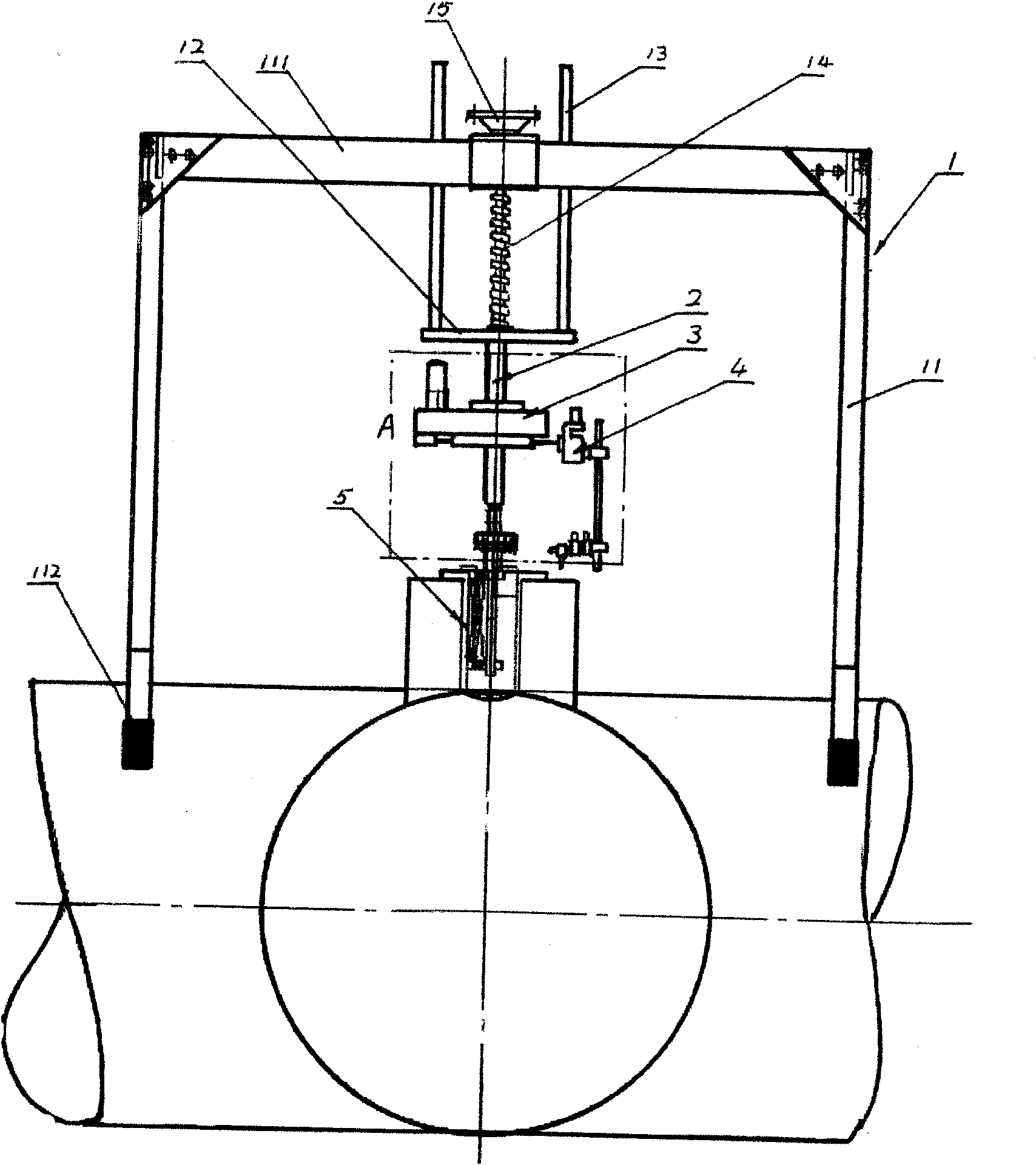

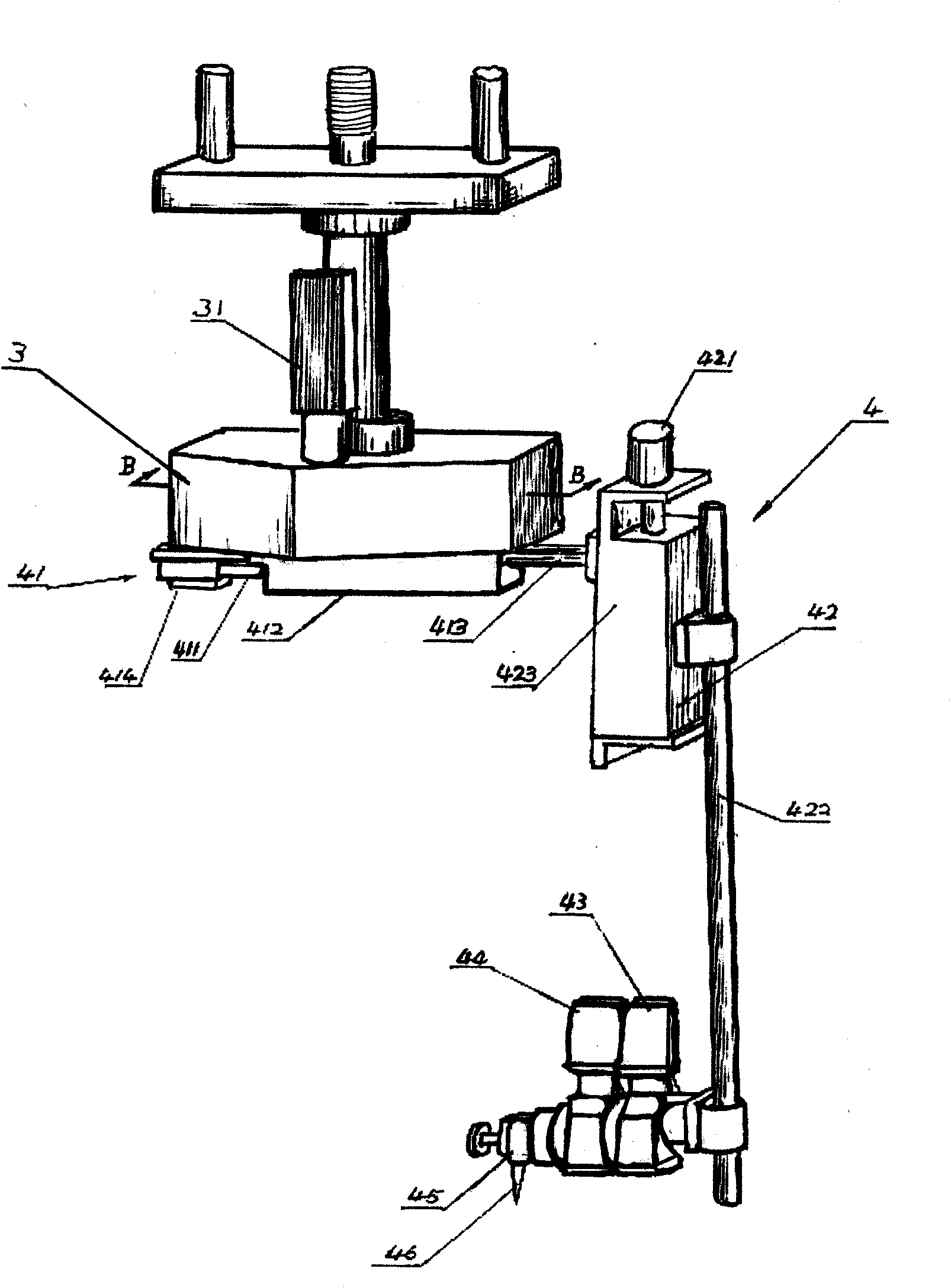

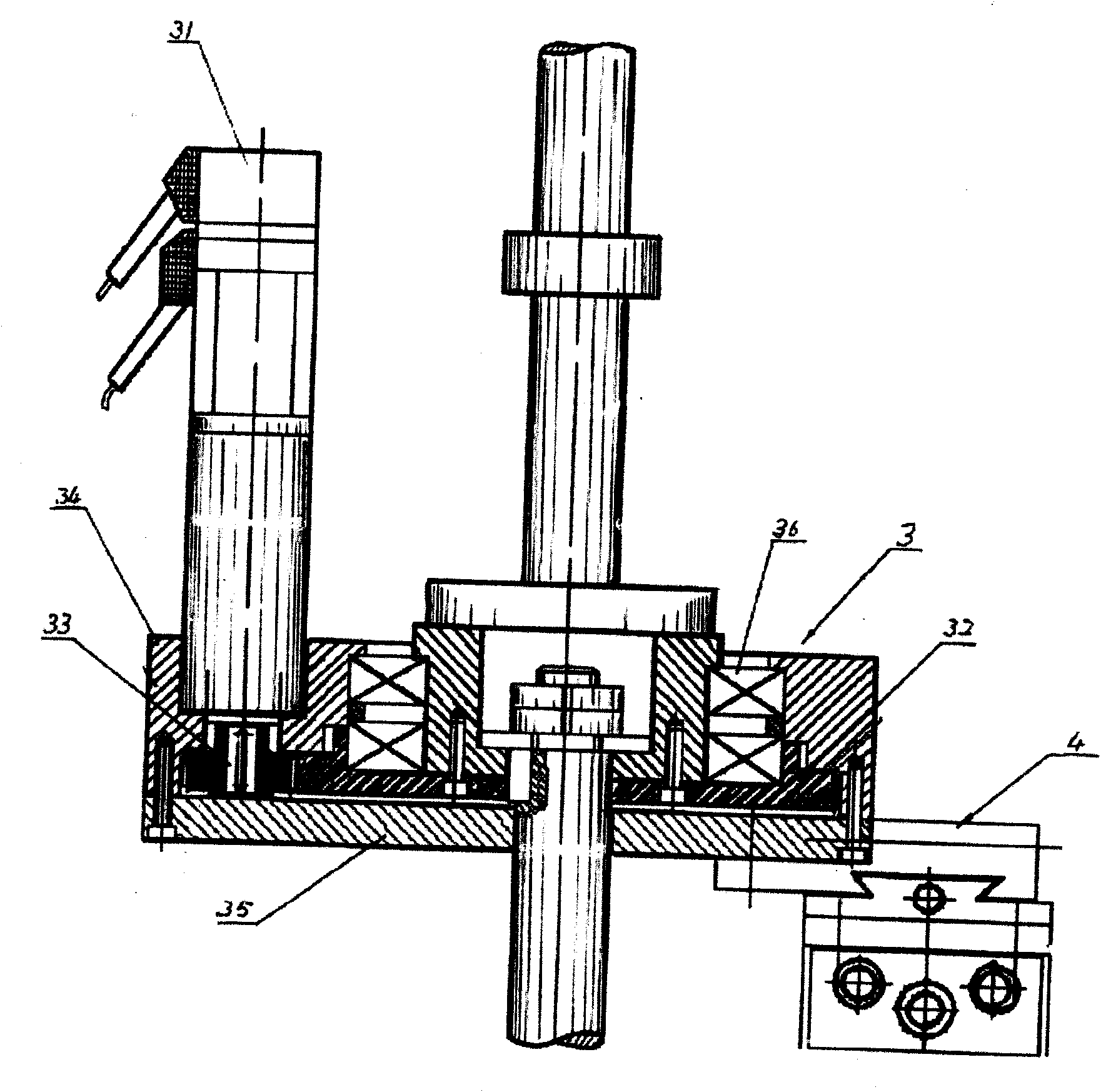

[0018] Depend on Figure 1 to Figure 4 Shown, a portable open-hole connection and saddle-shaped welding seam welding machine is mainly composed of a hanger (1), a main shaft (2), a rotating disk (3), a welding head (4) and a pipe expansion mechanism (5 ), wherein: the main body (11) of the hanger is formed by the profile piece (111) and the magnetic base (112), and the feed rod (13) and the main shaft connected by the screw (14) and the connecting plate (12) are arranged on it (2), hanger (1) and main shaft (2) are connected by lead screw (14), and lead screw (14) is connected with control handle (15) through hanger main body (11); The large gear (32) fixedly connected with the main shaft (2) and the rotating motor (31) fixedly connected with the outer disc (34) and equipped with a pinion (33) at the end are composed of the large gear (32) and the small The gears (33) are engaged, the bearing (36) is arranged between the outer disc (34) and the main shaft (2), and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com