Method for integrally forming aluminum alloy equal-diameter three-way member

An equal-diameter tee, integral forming technology, used in engine components, metal processing equipment, mechanical equipment, etc., can solve the problems of high performance requirements and low material utilization, improve material utilization, reduce welding and machining Process, the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

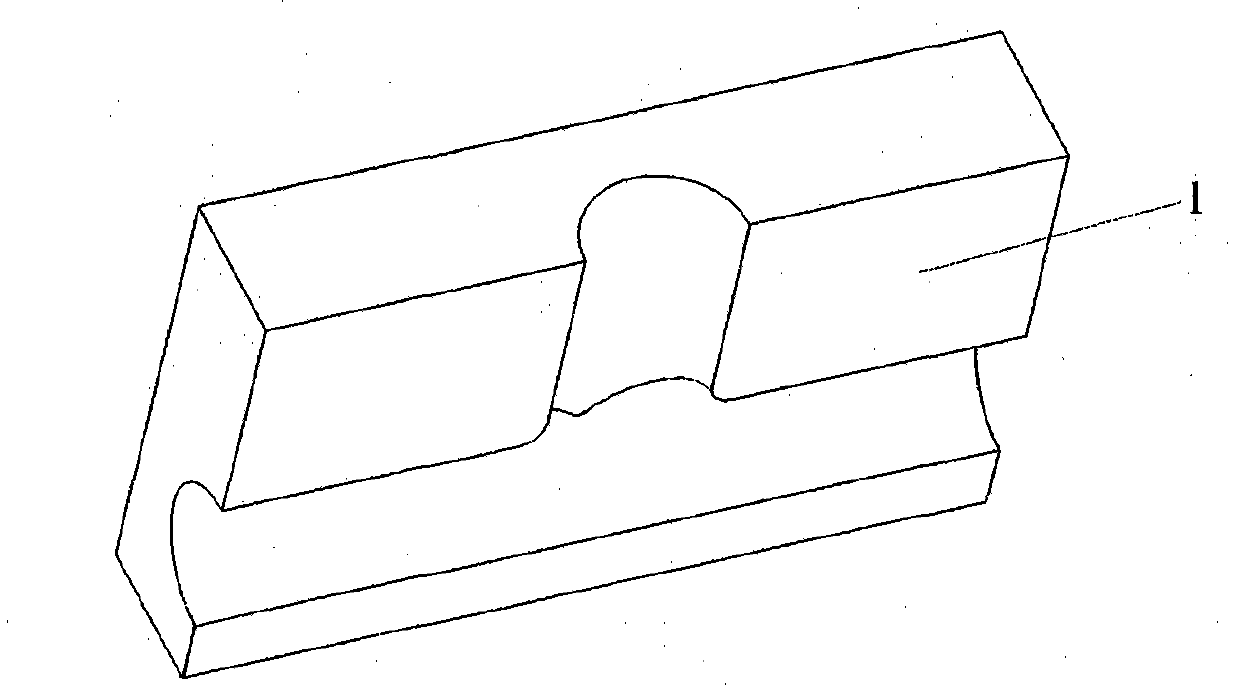

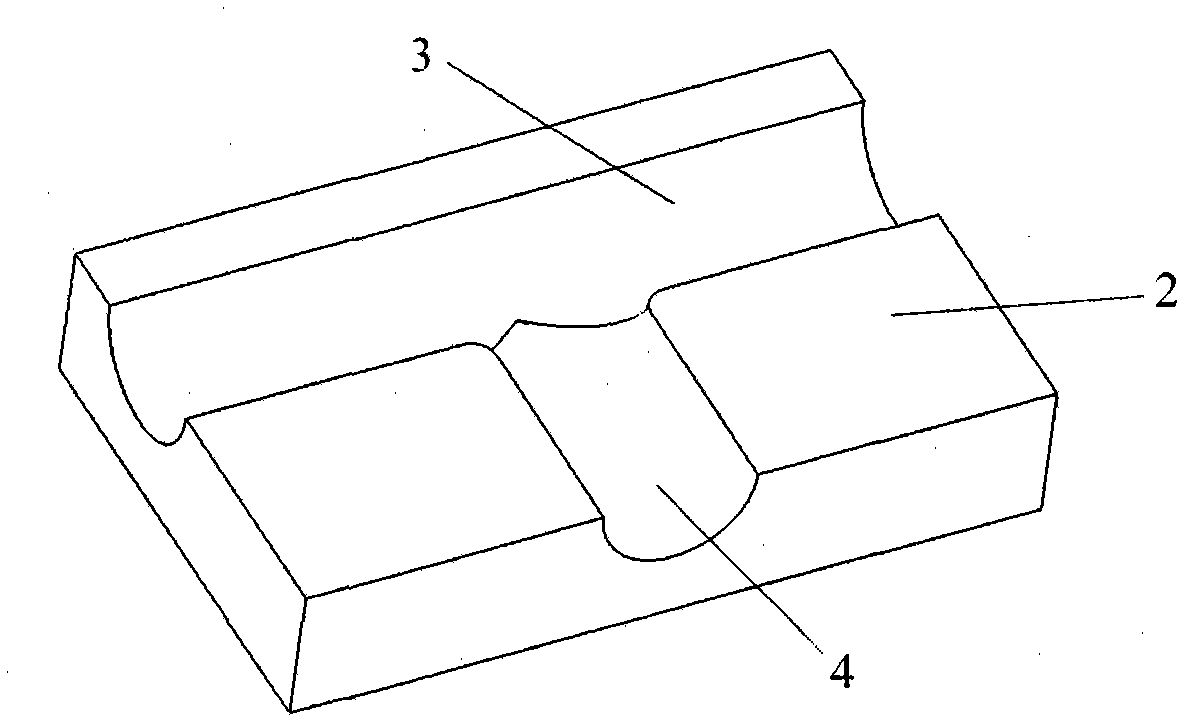

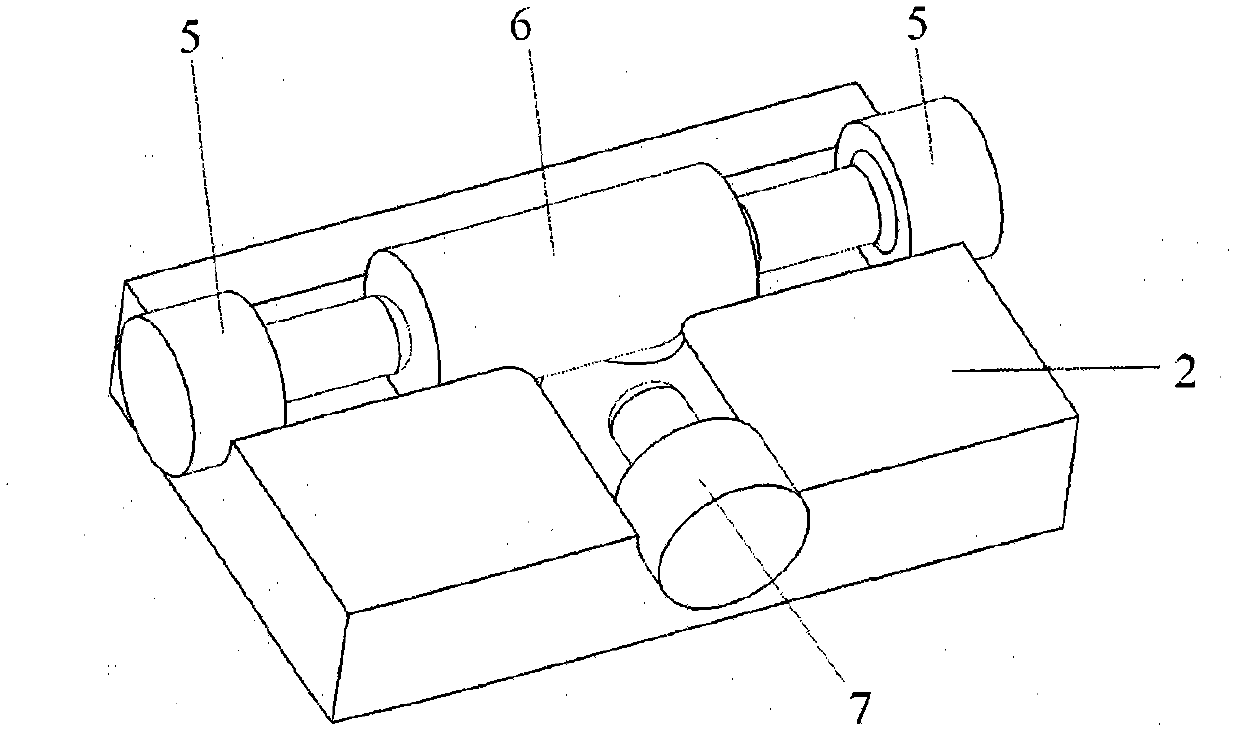

[0025] In this embodiment, a tee die is used to integrally form an aluminum alloy equal-diameter tee, and the formed tee includes a branch pipe 8 and a main pipe 9 . as attached figure 1 As shown, L is the height of the branch pipe, H is the depth of the main pipe, h is the depth of the branch pipe, and 0.5H<h<H, D1 is the inner diameter of the main pipe, D2 is the outer diameter of the main pipe, the inner and outer diameters of the branch pipe of the tee and the main pipe are correspondingly equal. In this embodiment, h=48mm, H=66mm, L=70mm, D1=32mm, D2=66mm.

[0026] In this embodiment, the above-mentioned tee is formed on a 40MN multi-directional die forging hydraulic press, and the specific steps are:

[0027] Step 1: Prepare the blank. The material selected in this example is 7075 aluminum alloy extruded bar. First, the bar is turned to a diameter smaller than the outer diameter of the main pipe of the tee by 1mm, that is, φ65mm, and then the blank is determined accor...

Embodiment 2

[0035] In this embodiment, a tee die is used to integrally form an aluminum alloy equal-diameter tee, and the formed tee includes a branch pipe 8 and a main pipe 9 . as attached figure 1 As shown, L is the height of the branch pipe, H is the depth of the main pipe, h is the depth of the branch pipe, and 0.5H

[0036] In this embodiment, the above-mentioned tee is formed on a 40MN multi-directional die forging hydraulic press, and the specific steps are:

[0037] Step 1: Prepare the blank. The material selected in this example is 7075 aluminum alloy extruded bar. First, the bar is turned to a diameter smaller than the outer diameter of the main pipe of the tee (0.5-1) mm, that is, φ59mm, and then according to the "volume...

Embodiment 3

[0045] In this embodiment, a tee die is used to integrally form an aluminum alloy equal-diameter tee, and the formed tee includes a branch pipe 8 and a main pipe 9 . as attached figure 1 As shown, L is the height of the branch pipe, H is the depth of the main pipe, h is the depth of the branch pipe, and 0.5H

[0046] In this embodiment, the above-mentioned tee is formed on a 40MN multi-directional die forging hydraulic press, and the specific steps are:

[0047] Step 1: Prepare the blank. The material selected in this example is 7075 aluminum alloy extruded bar. First, the bar is turned to a diameter smaller than the outer diameter of the main pipe of the tee (0.5 ~ 1) mm, that is, φ64mm, and then according to the "volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com