Silver chloride-silver phosphate composite photocatalyst and preparation method thereof

A technology of silver phosphate and silver chloride, which is applied in the field of photocatalysis, can solve the problem of low photocatalytic activity, achieve the effect of improving reaction activity, facilitating large-scale promotion, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of a silver chloride-silver phosphate composite visible light catalyst comprises the steps:

[0026] Weigh 1.1688g or 0.02mol NaCl solid, and 0.7602g or 0.002mol of Na 3 PO 4 12H 2 O was dissolved in 200ml deionized water and stirred for 10min to obtain a mixed solution of phosphate ions and chloride ions;

[0027] Another weighed 4.4166g or 0.026mol AgNO 3 Dissolve in 200ml deionized water, stir for ten minutes to obtain silver nitrate solution;

[0028] Use a dropper to slowly add the silver nitrate solution dropwise to the mixed solution of phosphate ion and chloride ion prepared above, continue stirring for 4 to 5 hours after the dropwise addition, filter the suspension, wash it, and dry it at 60°C. Grind to get yellow Ag 3 PO 4 And the molar ratio of AgCl, that is, chloride ion: phosphate ion is 1:0.1 Ag 3 PO 4 / AgCl composite photocatalyst nanoparticles, the particle size of which is 10-100nm.

Embodiment 2

[0030] When the molar weight of the supported silver phosphate is 0, the preparation of a silver chloride visible light catalyst comprises the following steps:

[0031] Weigh 1.1688g, that is, 0.02mol NaCl solid, dissolve it in 200ml deionized water, and stir for 10min to obtain a sodium chloride solution;

[0032] Another weighed 3.3974g or 0.02mol of AgNO 3 Dissolve in 200ml deionized water, stir for 10min to obtain silver nitrate solution;

[0033] Use a dropper to slowly add the silver nitrate solution to the sodium chloride solution prepared above, and continue stirring for 4 to 5 hours after the addition is completed, filter the suspension, wash, dry at 60°C, and grind to obtain yellow chlorine dioxide. Silver Visible Light Catalyst.

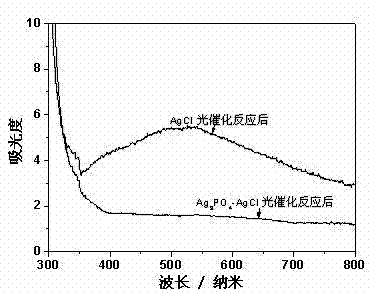

[0034] figure 1 Ag obtained for the above-mentioned embodiment 1 3 PO 4 / AgCl composite photocatalyst and the X-ray diffraction (XRD) pattern of the silver chloride visible light catalyst of embodiment 2 gained, by comparing with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com